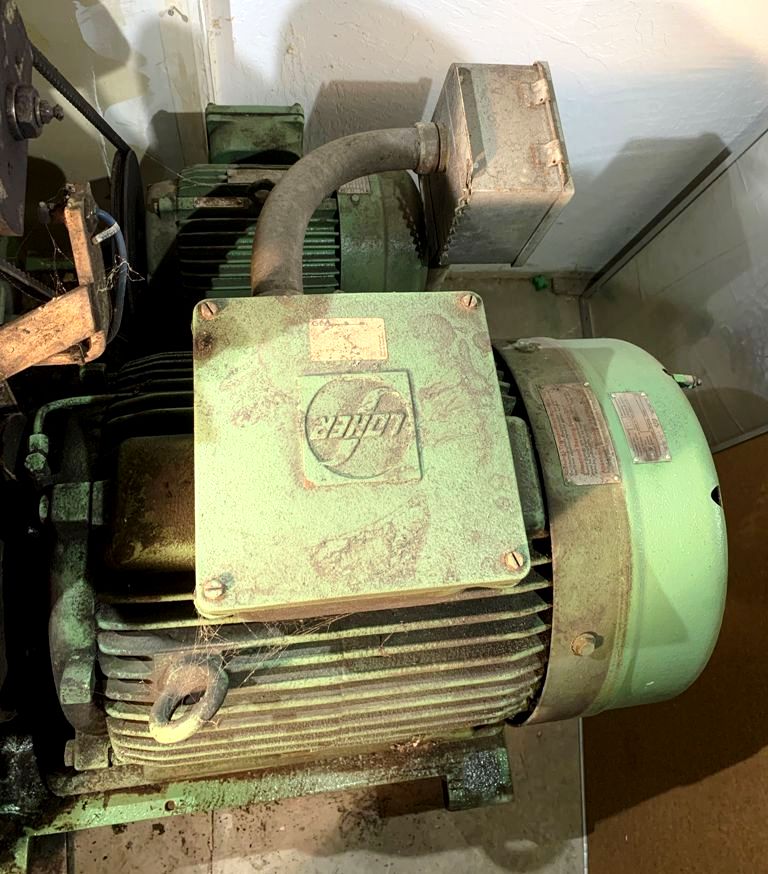

Description:

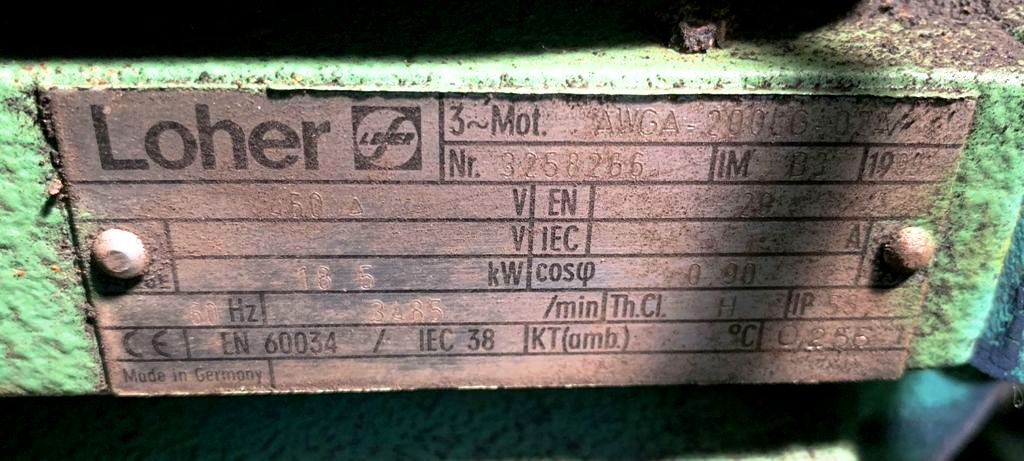

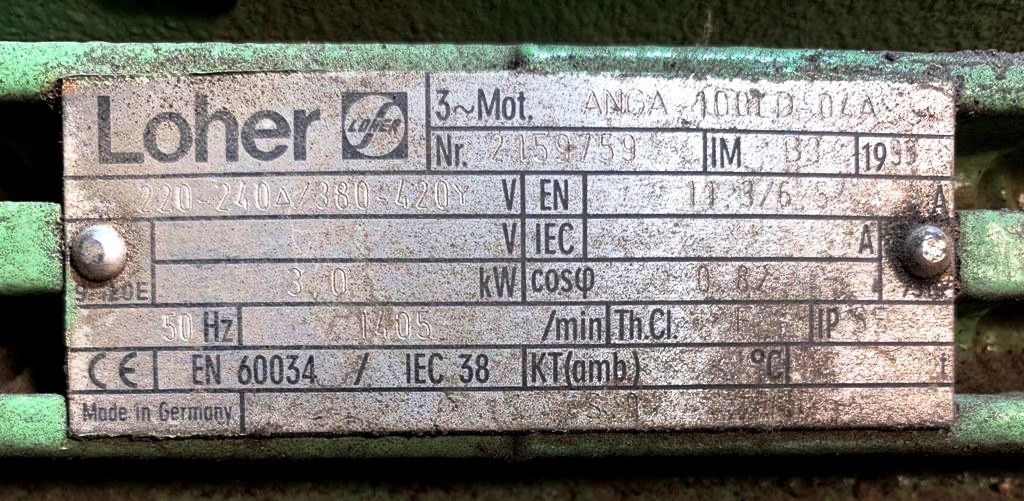

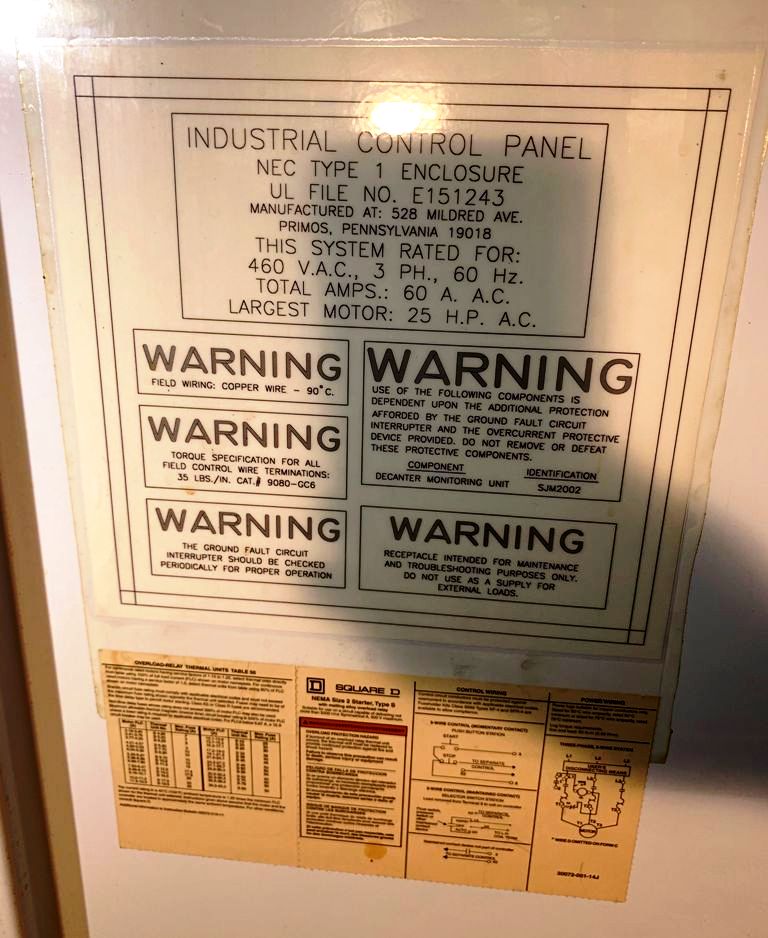

Max bowl speed 3500 RPM, 2300 G's, rated @ 25 GPM, pressure discharge design, 18.5 KW motor 460/3/60/3550 RPM, cyclo gearbox, 3 KW backdrive, guards, sludge pump, feed tube, chutes and control panel with VFDs. 1999 vintage. Very good condition. Exclusive.

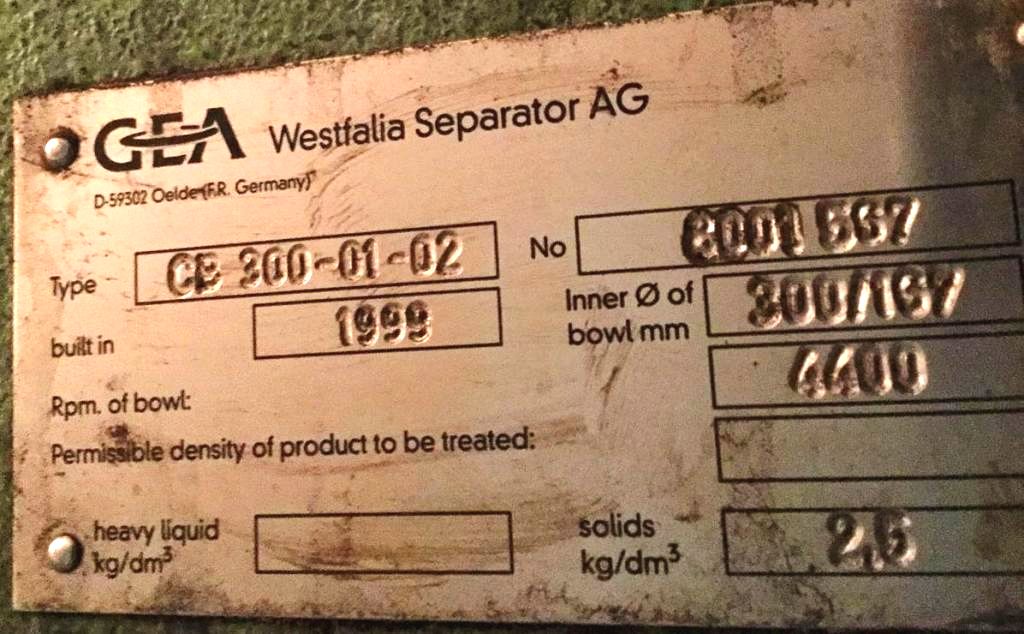

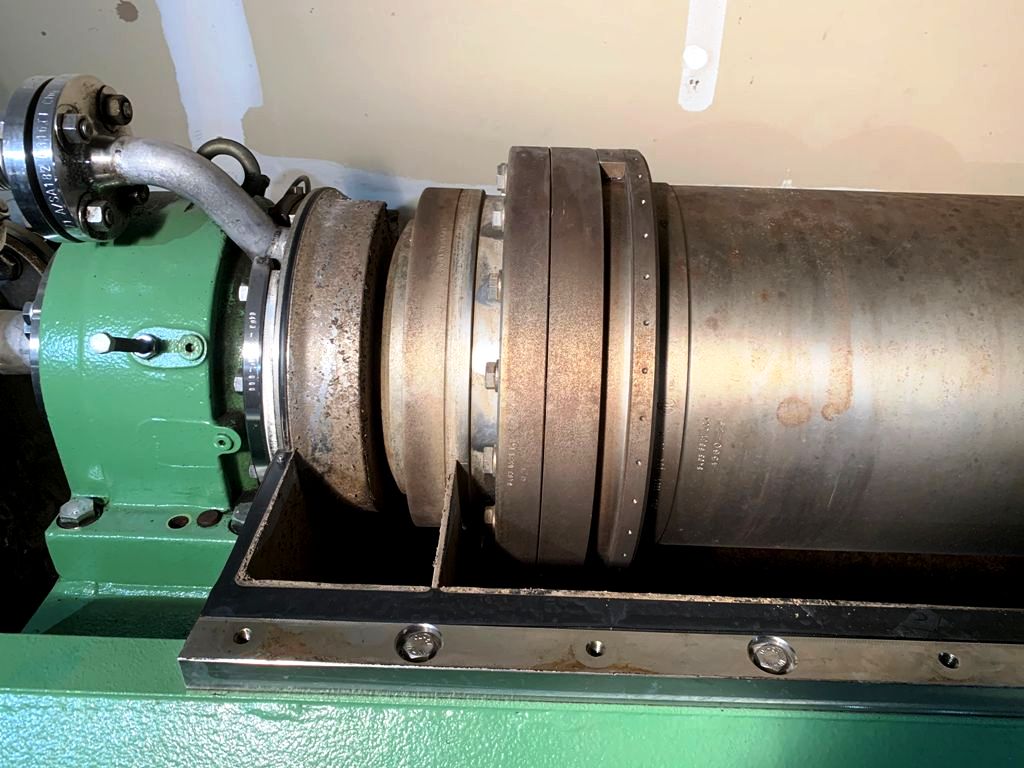

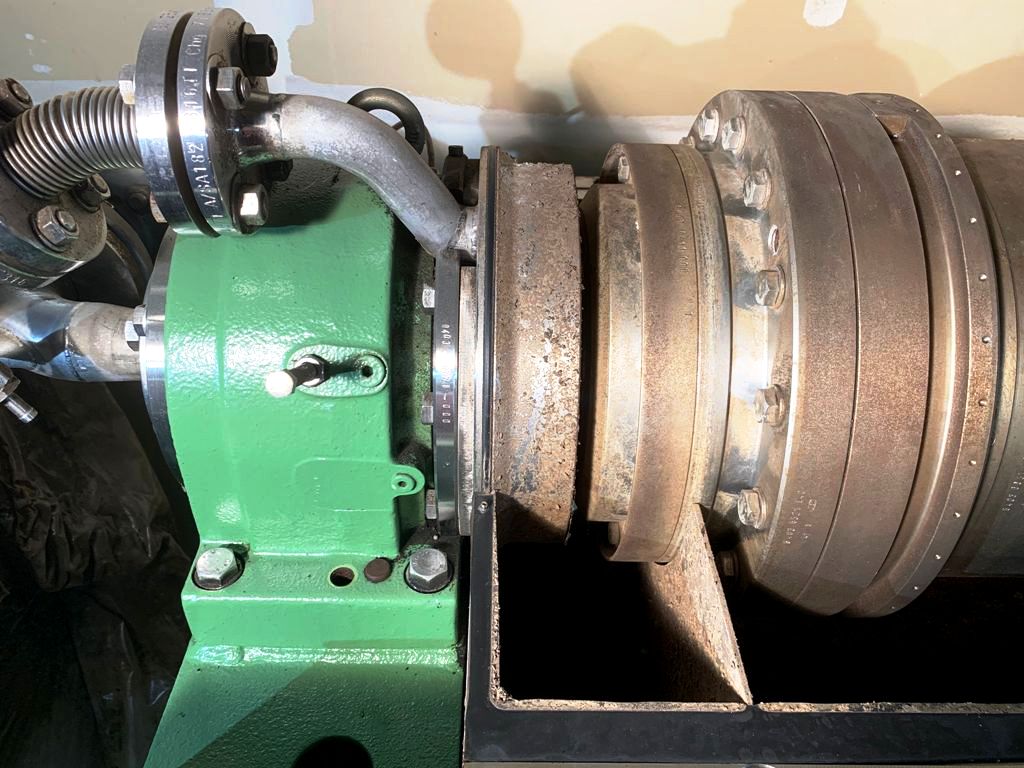

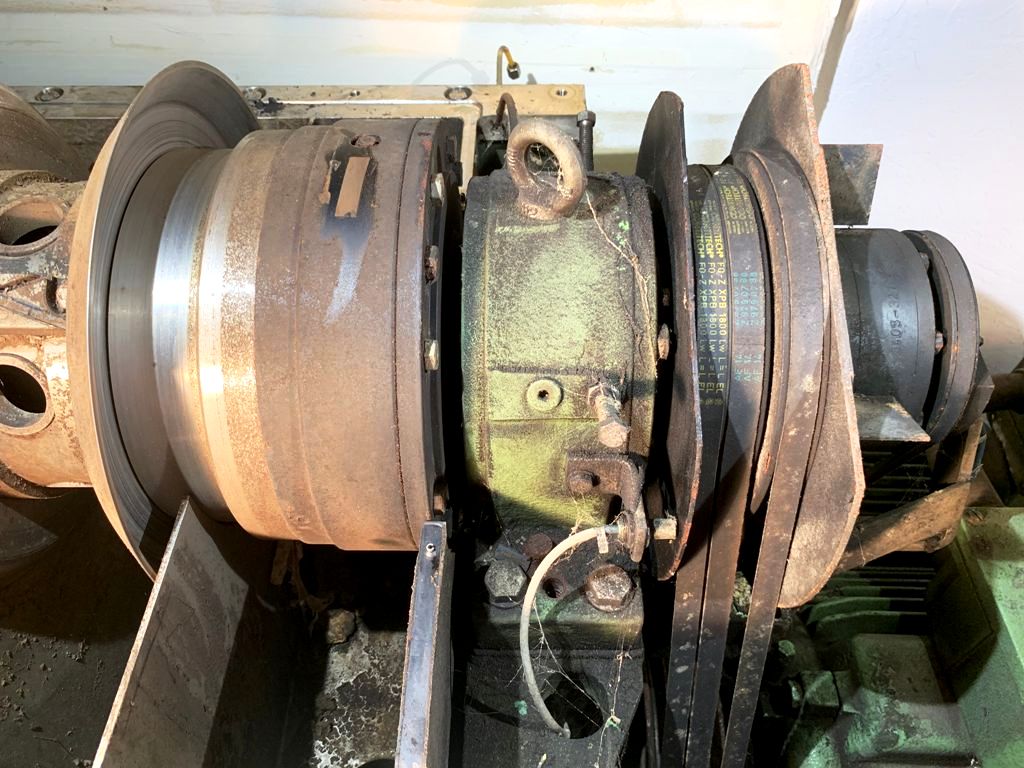

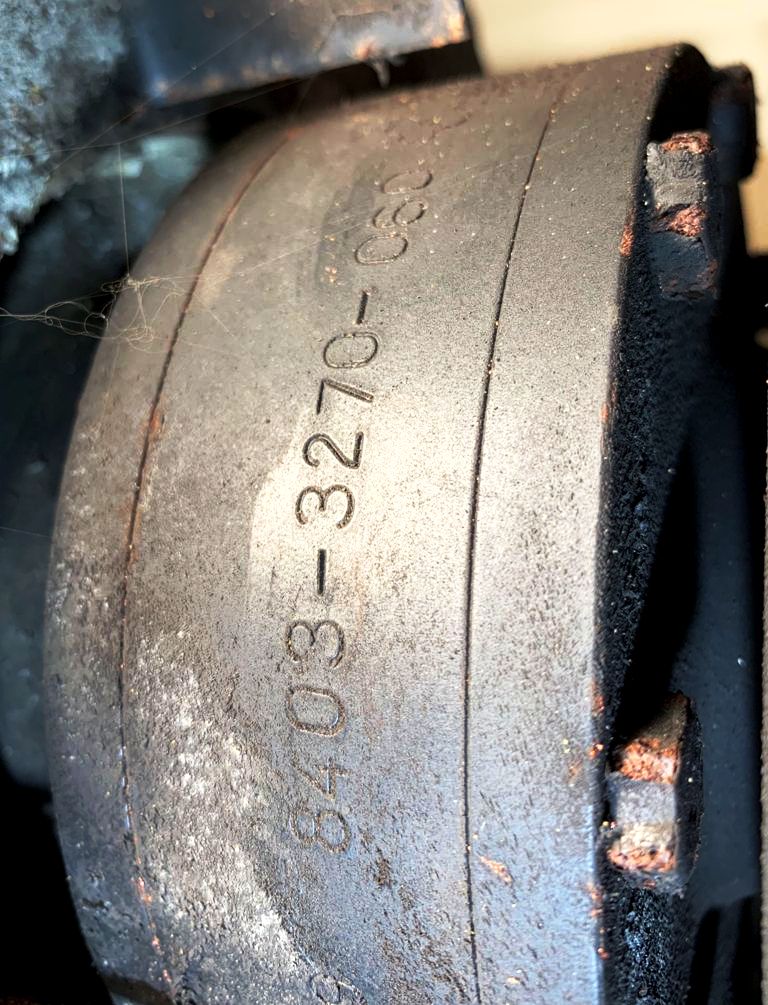

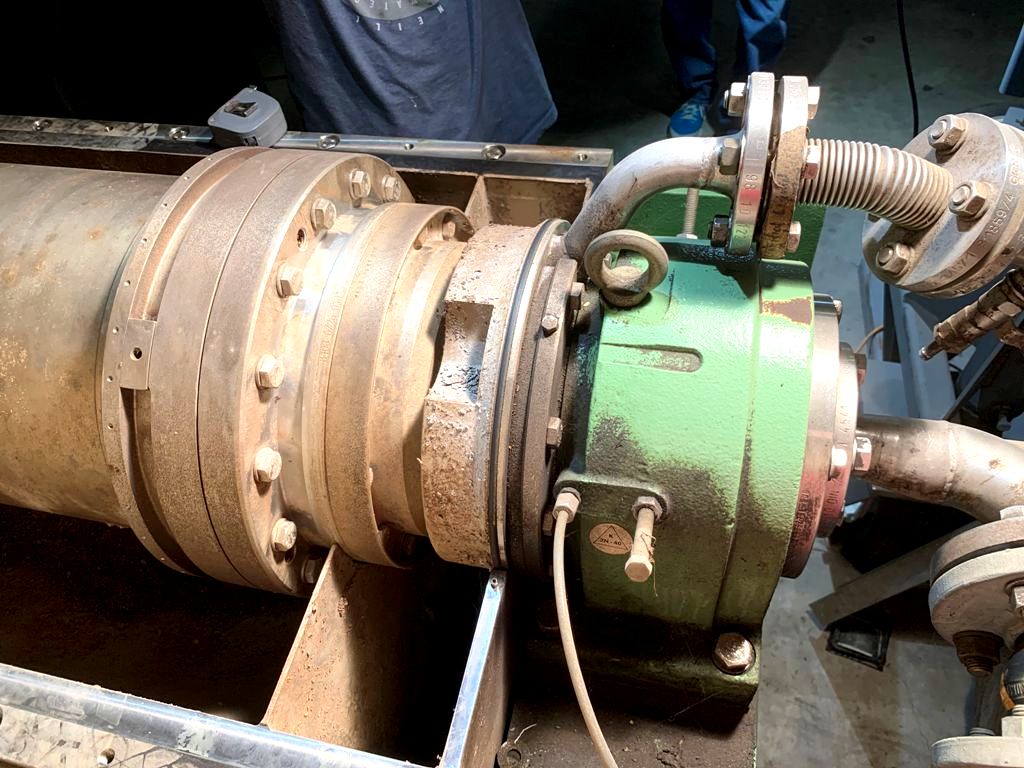

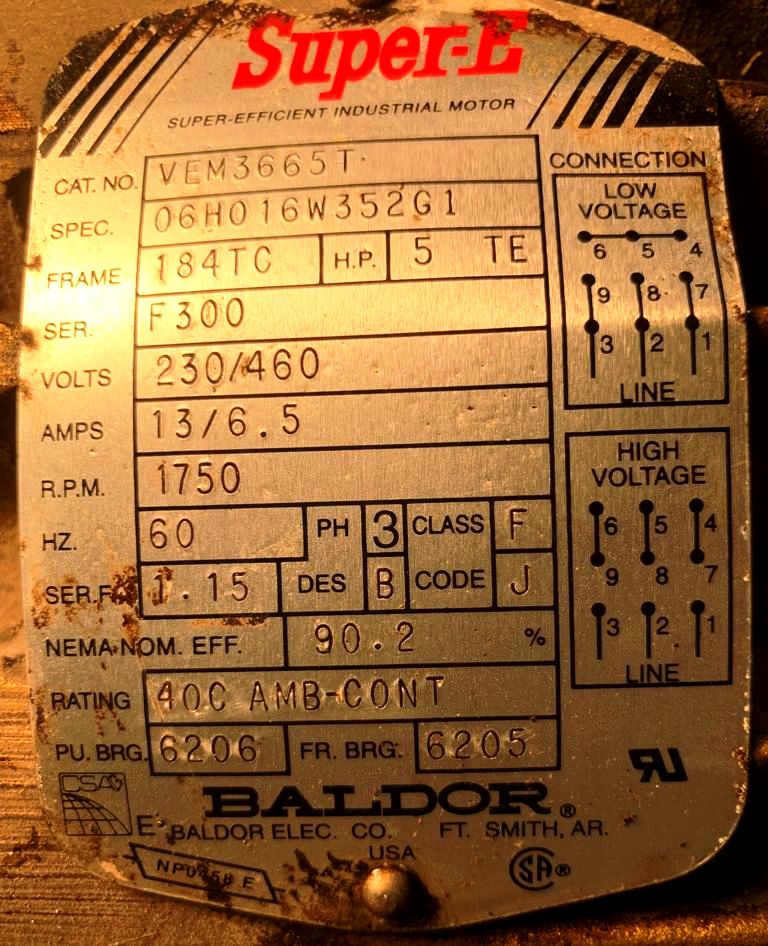

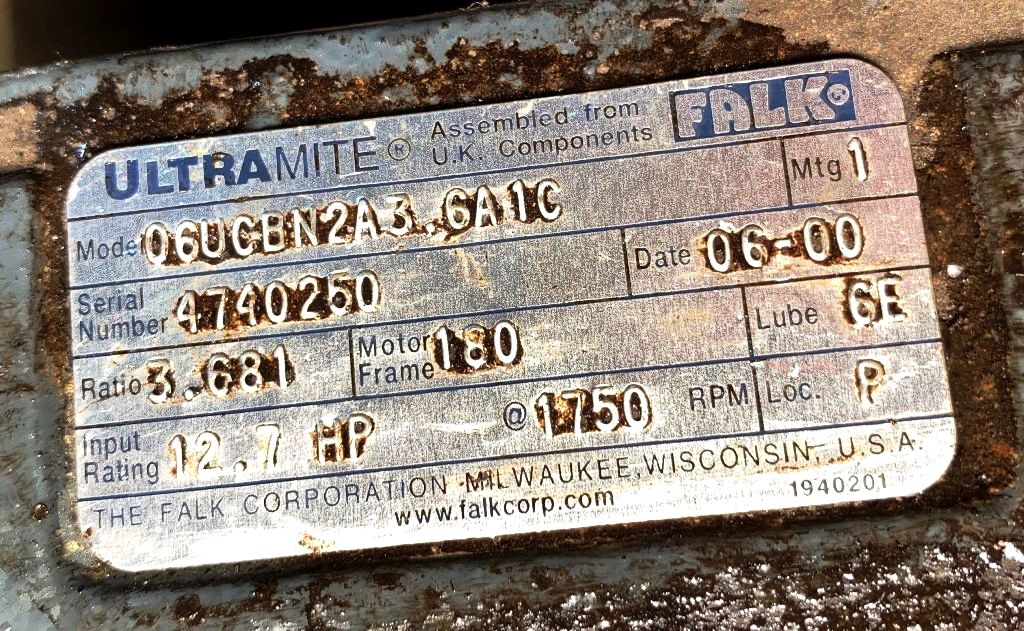

The Westfalia CB 300-01-02 decanter centrifuge, 316SS. is engineered for optimal performance in a variety of industrial applications, particularly in the separation of solids from liquids. With a maximum bowl speed of 3500 RPM and the capability to generate forces up to 2300 G's, this centrifuge is designed to efficiently handle high volumes of material, rated at 25 gallons per minute (GPM). The pressure discharge design enhances the separation process, allowing for effective removal of solids while maintaining the integrity of the liquid phase. This is particularly beneficial in industries such as food processing, wastewater treatment, and chemical manufacturing, where purity and efficiency are paramount. The robust 18.5 KW motor, operating at 460V, 3-phase, 60Hz, ensures that the centrifuge can perform consistently under demanding conditions, while the cyclo gearbox provides reliable torque transmission for sustained operation.

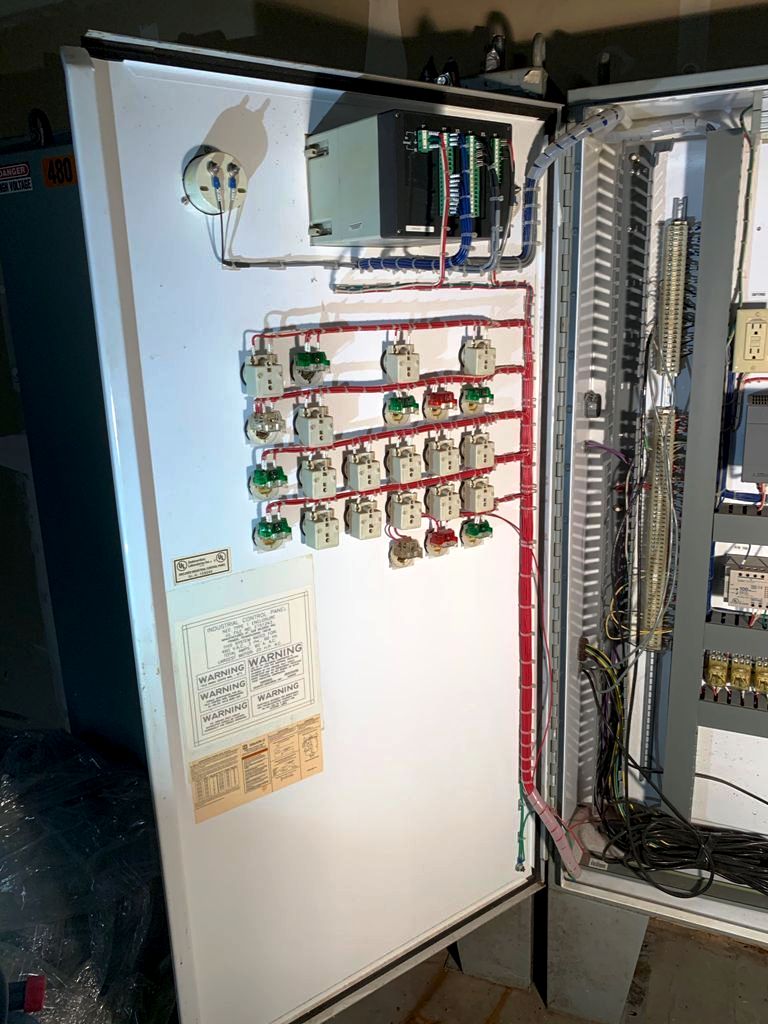

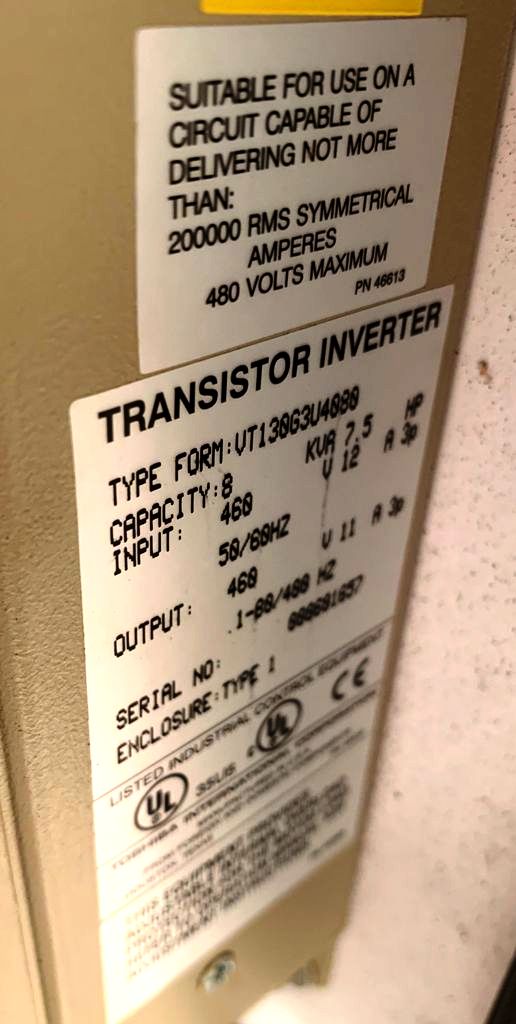

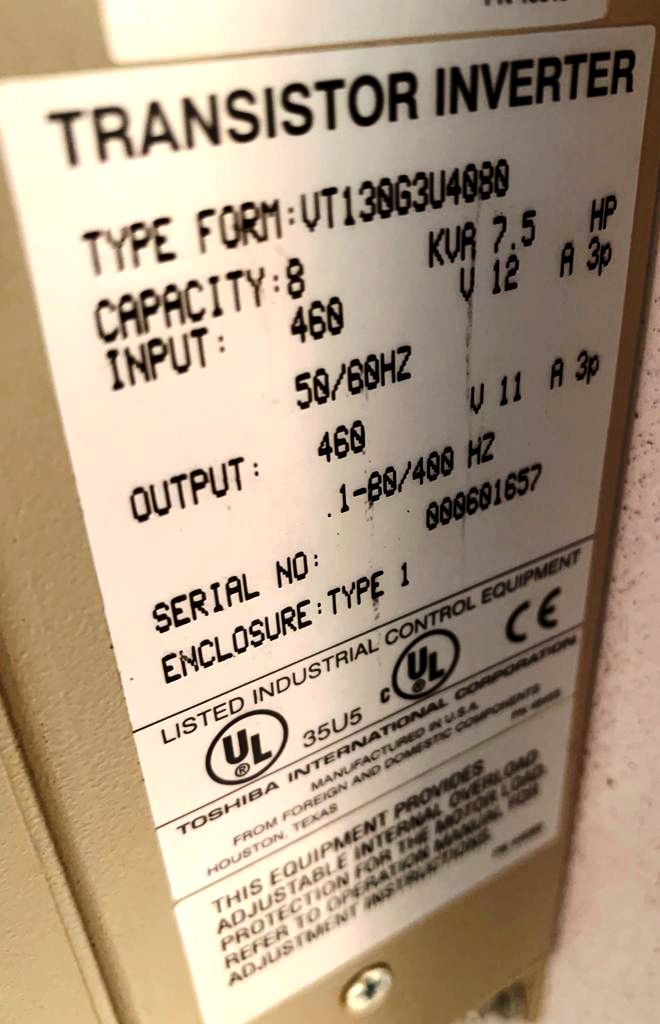

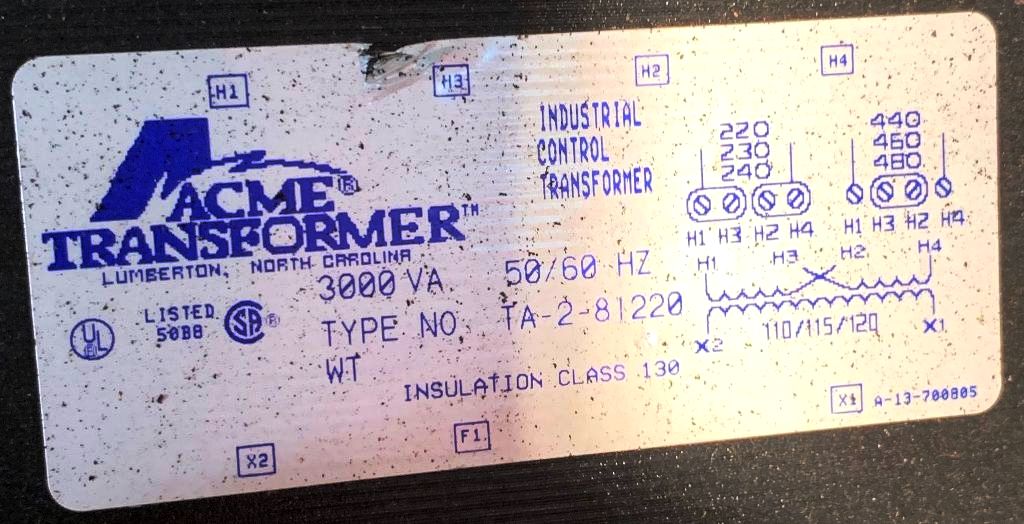

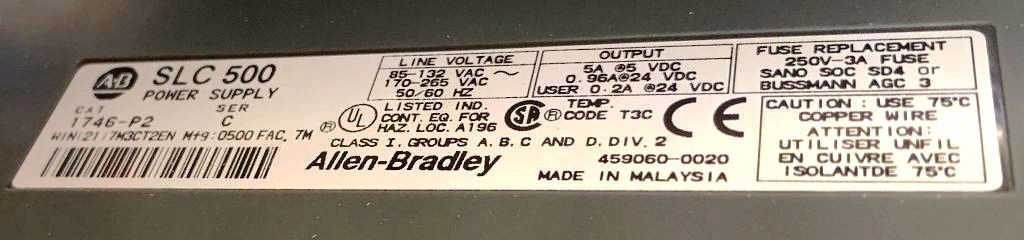

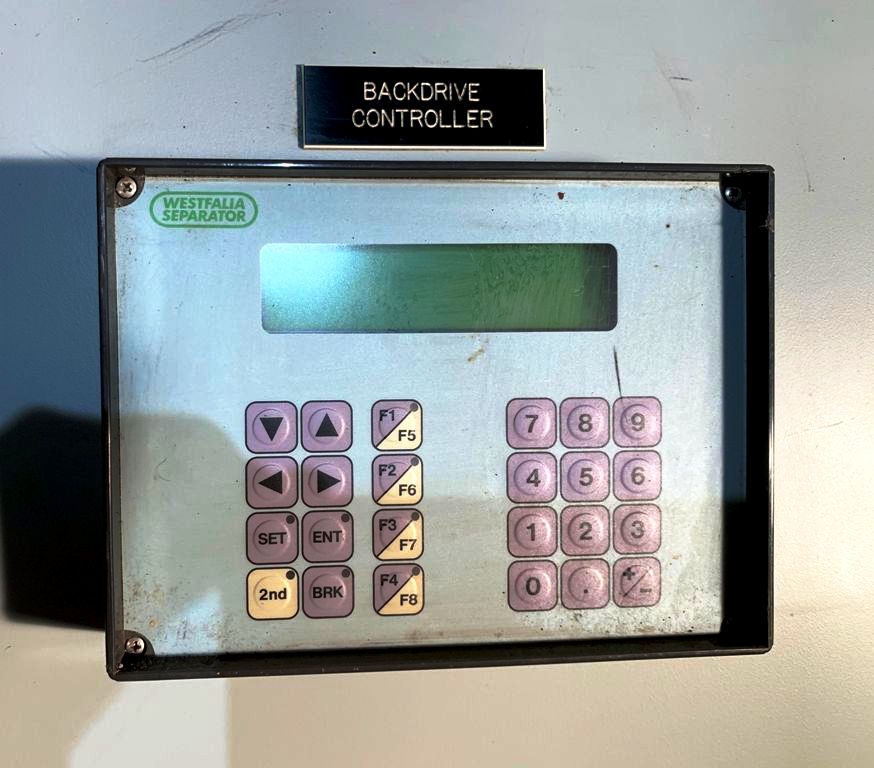

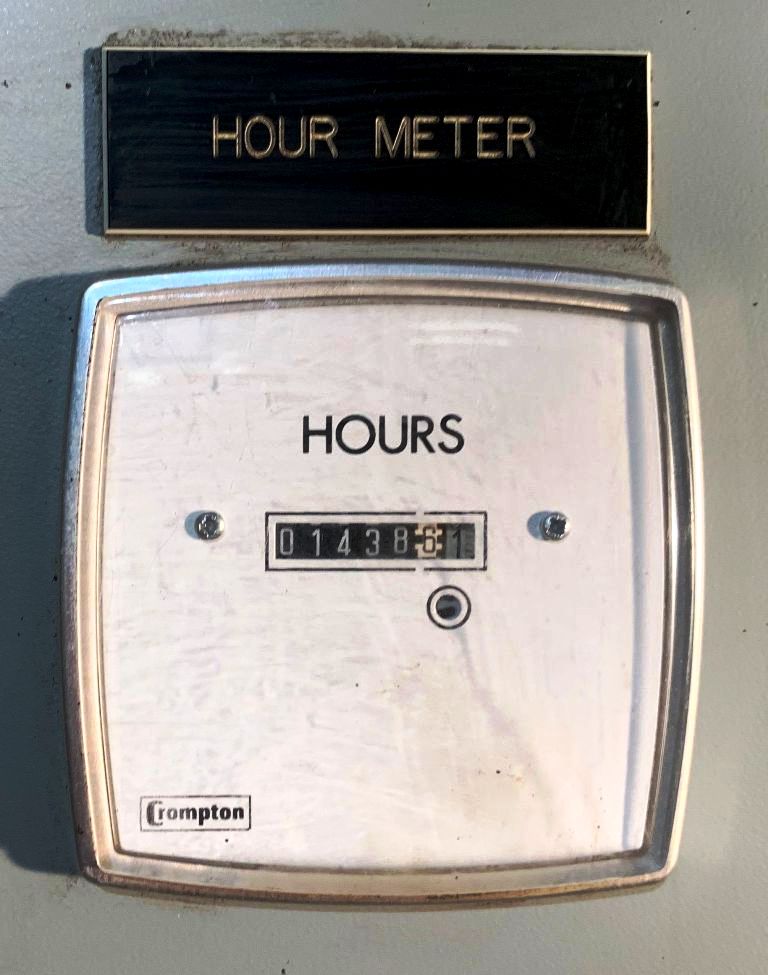

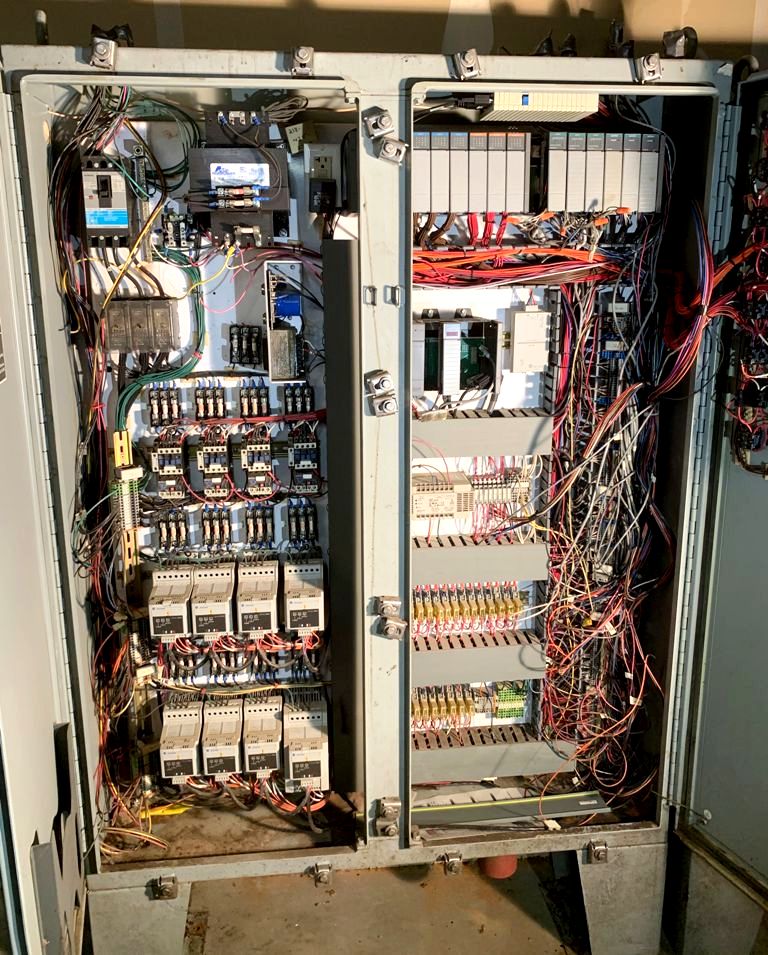

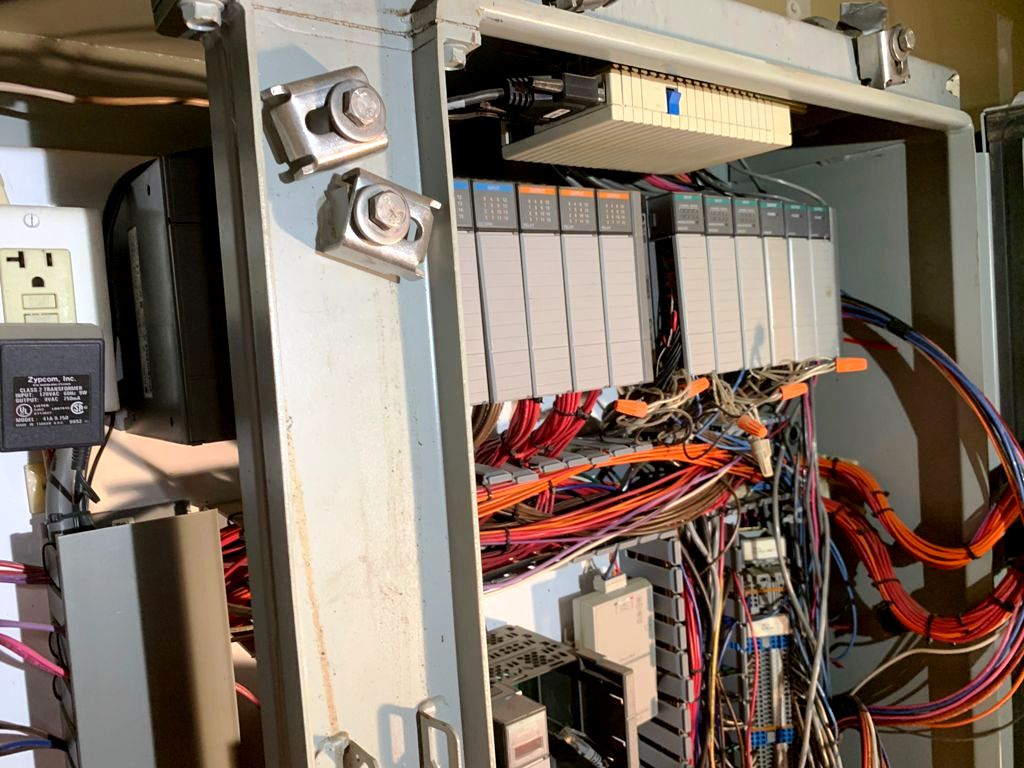

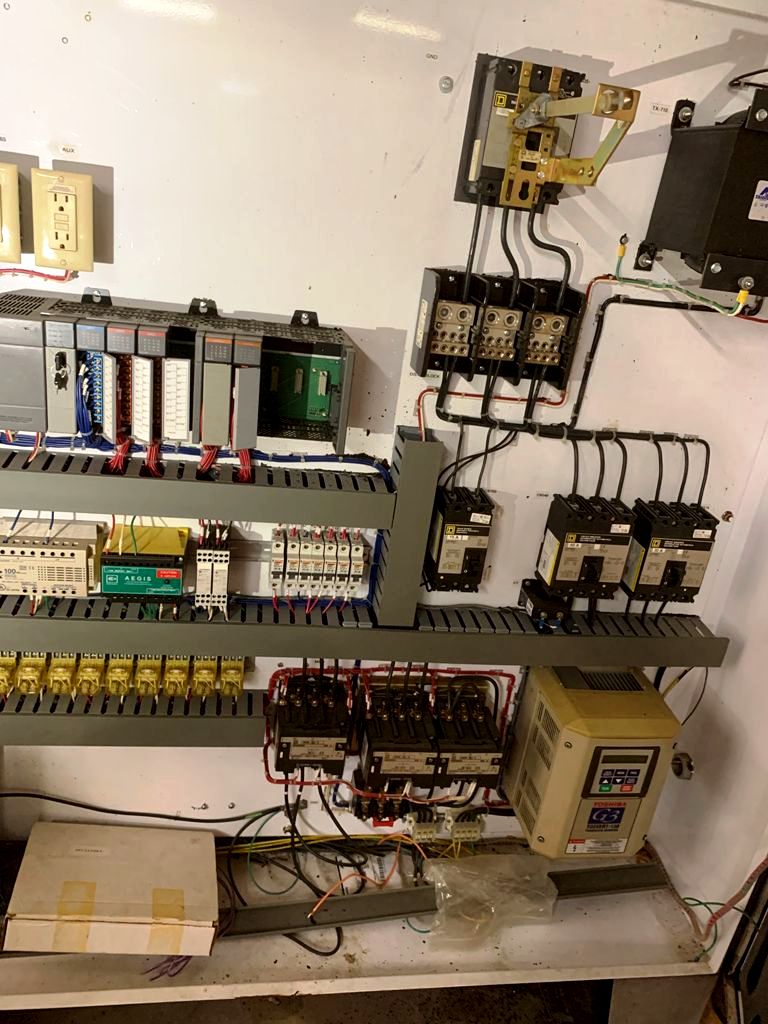

In addition to its powerful motor, the Westfalia CB 300-01-02 decanter centrifuge features a 3 KW backdrive, which allows for easy reverse operation when necessary, facilitating maintenance and cleaning processes. Safety is also a priority, as evidenced by the inclusion of guards that protect operators from moving parts. The unit comes equipped with a sludge pump, feed tube, and chutes, which streamline the feeding and discharge processes, making it user-friendly and efficient. Furthermore, the integrated control panel with variable frequency drives (VFDs) allows for precise control over the centrifuge's operational parameters, enabling users to adjust speeds and optimize performance based on specific application needs. With its 1999 vintage, this centrifuge has been maintained in very good condition, making it a valuable addition to any industrial operation looking to enhance its separation capabilities.

Key Features:

High-Speed Performance, Durable Construction, Efficient Solid-Liquid Separation, User-Friendly Design, Advanced Control Features