Description:

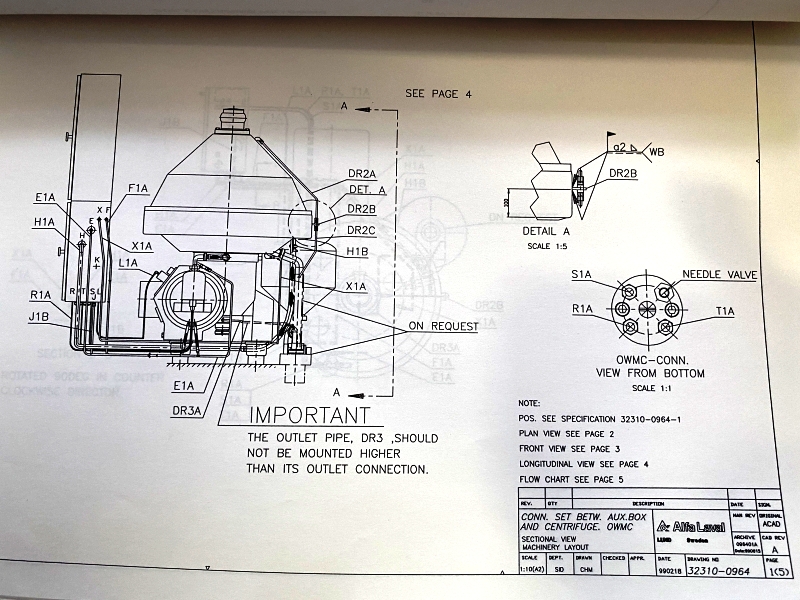

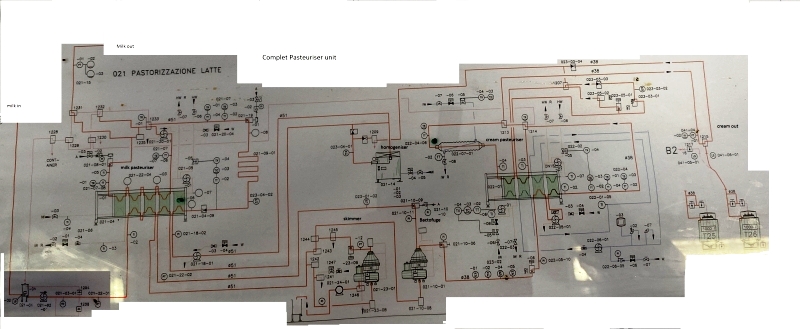

Complete milk pasteurization and standardization line. Pasteurizer: Alfa Laval M10 / M6 / Alfast / SHL 20, balance tank with float, constant flow control unit, Alfa-Laval LKH 25/190 SSS 5.5 KW pump. Heat exchanger: Alfa-Laval M10-FMC, 10 bar pressure. Over-pressure system: ALC2 /110 7.5 KW booster pump and (3) E&H Cerabar pressure transmitters. Holding tubes 20 sec or 60 sec, temperature scheme milk: in 4°C to separators and homogenizer at approx. 60°C - 75°C -4°C. Skimmer: Alfa-Laval MRPX 614 HGV-74C-50, 22 KW motor, tools, OWM, LKH 112 FSS 5.5 KW inlet pump with flushed seal. Standardization unit: Tetra Alfast for milk and cream, including flow transmitters, valves, and control panel. Homogenizer: partial stream (all cream and part of skim milk is homogenized) 2 stage. Cream pasteurizer: temperature scheme: in 55°C - 85°C - 4°C. Plate heat exchanger: Alfa-Laval M6, 3000 LPH capacity. All cream in this line is pasteurized. The outlet of surplus cream is transported to a transport tank. Controls excluded. Includes all interconnecting piping and valves. Software available. 1992 vintage. Optional: Tetra-Pak BBRPX 714 HGV-34C Bactofuge with internal recirculation, 22 KW motor, OWM and set of tools. 1999 vintage. Excellent condition. FCA Europe.

The Alfa-Laval 12-15,000 LPH milk pasteurization and standardization line is engineered to meet the rigorous demands of modern dairy processing. This comprehensive system is designed not only for efficiency but also for maintaining the highest standards of product quality. The heart of the line is the Alfa Laval M10 / M6 / Alfast / SHL 20 pasteurizer, which ensures that milk is subjected to precise temperature control during the pasteurization process. This is crucial for eliminating harmful bacteria while preserving the nutritional integrity and flavor of the milk. The system also features a balance tank equipped with a float and a constant flow control unit, ensuring smooth operation and consistent product flow throughout the pasteurization process. The Alfa-Laval LKH 25/190 SSS pump, with a power output of 5.5 KW, is integral in maintaining the necessary pressure and flow rates, thereby enhancing the overall efficiency of the line.

In addition to the pasteurizer, the line includes a sophisticated heat exchanger, the Alfa-Laval M10-FMC, capable of handling pressures up to 10 bar. This component is vital for optimizing heat transfer and energy efficiency, contributing to lower operational costs. The over-pressure system, featuring the ALC2 /110 booster pump and three E&H Cerabar pressure transmitters, ensures that the system operates safely and effectively under varying conditions. The holding tubes, designed for either 20 or 60 seconds, facilitate the required retention time for effective pasteurization. Furthermore, the standardization unit, Tetra Alfast, is equipped with flow transmitters and valves, allowing for precise adjustments to the milk and cream ratios, ensuring that the final product meets specific fat content requirements. This line is not only efficient but also user-friendly, with interconnecting piping and valves included, making installation and maintenance straightforward.

Key Features:

High Efficiency, Advanced Temperature Control, Robust Construction, User-Friendly Design, Comprehensive Processing Capabilities

Frequently Asked Questions

We're sorry, but this item has been sold.

Please consider the alternatives below.