Description:

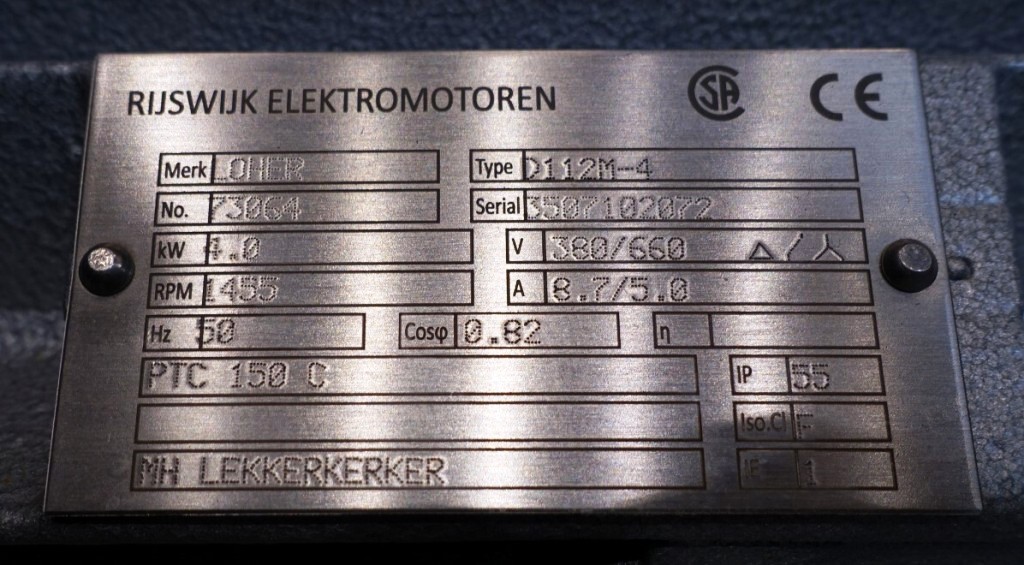

Max bowl speed 9210 RPM, rated @ 5000 LPH, heavy liquid phase discharged under pressure. 4 KW motor 380/3/50/1450 RPM, sludge tank, water valves, water harness, water filter, tools, PLC control panel with VFD, unitized on a SS stand with manual and PID. 1990 vintage. Reconditioned to "as new" with 6 month full mechanical warranty. Located in Europe.

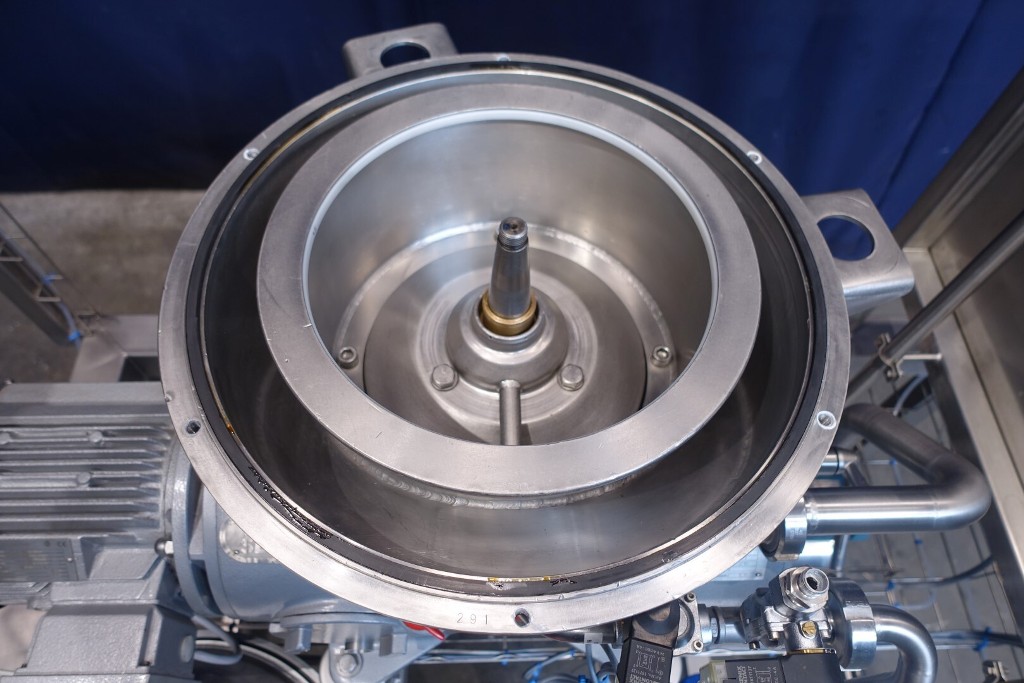

The Westfalia SB 7-03-076 fat separator, 316SS, is engineered for high-efficiency separation of fats, oils, and solids from liquid waste streams, making it an essential component for various industrial applications. With a maximum bowl speed of 9210 RPM and a rated capacity of 5000 liters per hour (LPH), this separator is designed to handle substantial volumes while ensuring optimal performance. The heavy liquid phase is discharged under pressure, facilitating effective separation and minimizing downtime during operation. The unit is powered by a robust 4 kW motor operating at 380V/3/50Hz and 1450 RPM, ensuring reliable and consistent performance even in demanding environments. The inclusion of a sludge tank, water valves, water harness, and water filter further enhances its operational efficiency, allowing for seamless integration into existing systems.

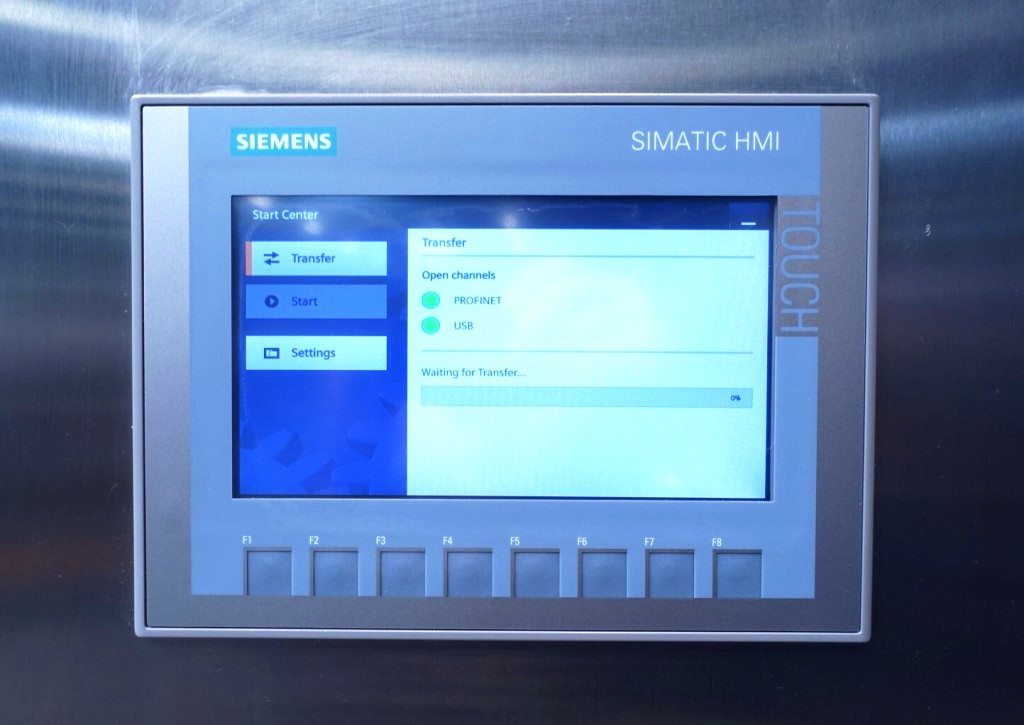

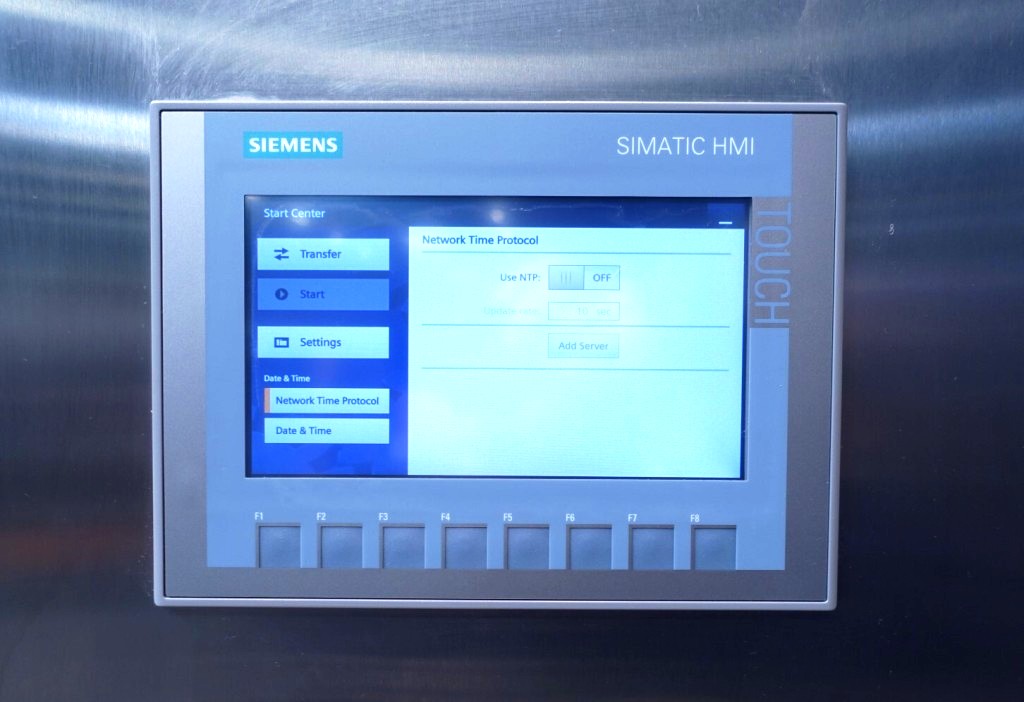

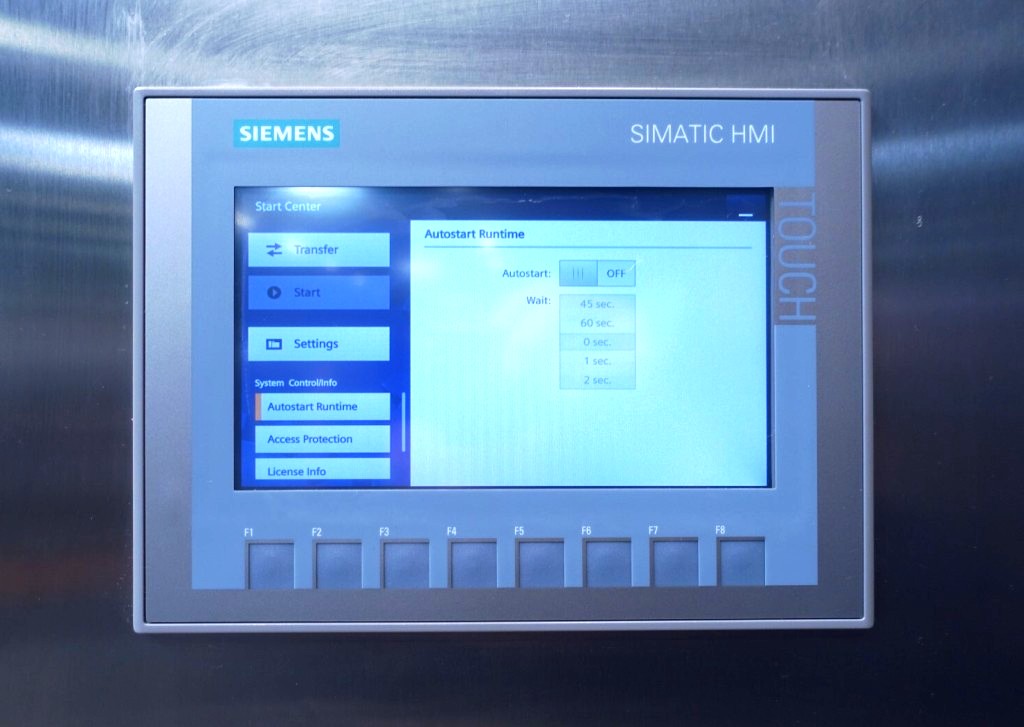

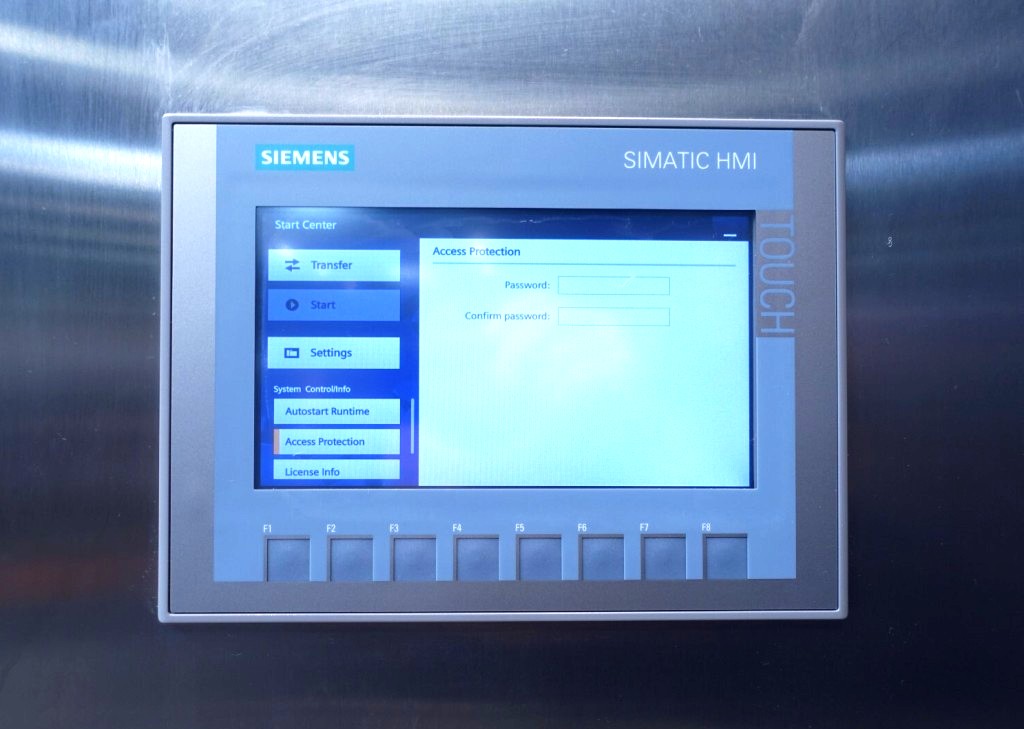

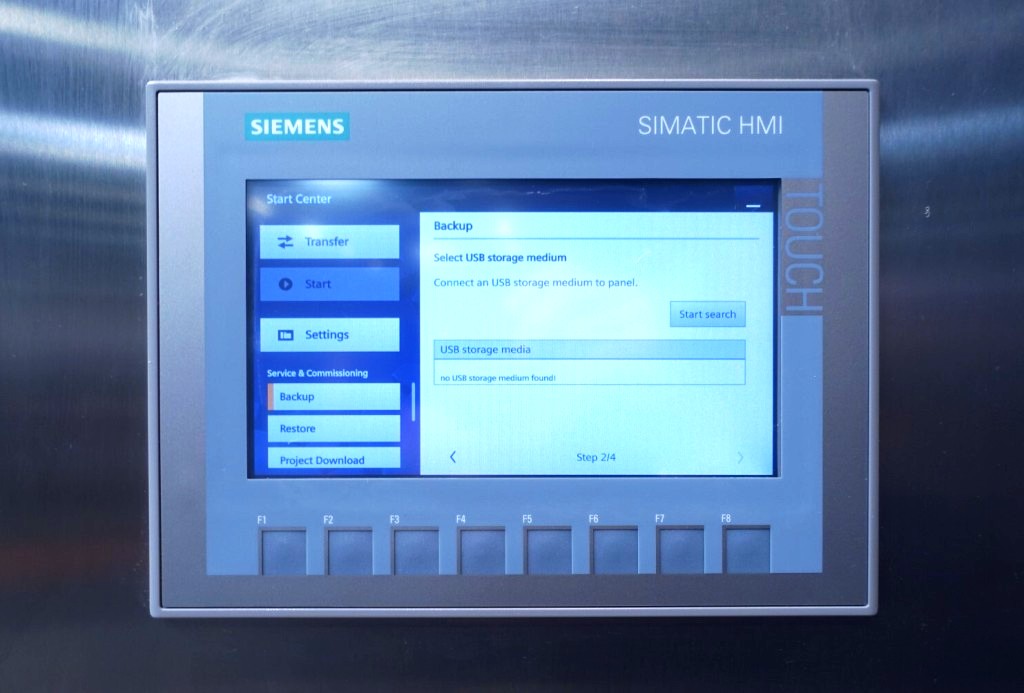

The Westfalia SB 7-03-076 fat separator, 316SS, is not only built for performance but also designed with user convenience in mind. It features a PLC control panel equipped with a Variable Frequency Drive (VFD), enabling precise control over the separation process and allowing operators to adjust parameters as needed for optimal results. The unitized stainless steel stand provides stability and durability, ensuring that the separator remains secure during operation. Additionally, this model has been reconditioned to 'as new' condition, reflecting a commitment to quality and reliability. With a comprehensive 6-month full mechanical warranty, buyers can have confidence in their investment. This equipment is located in Europe, making it accessible for various industrial sectors looking to enhance their waste management processes.

Key Features:

High-Speed Performance, Durable Stainless Steel Construction, User-Friendly PLC Control Panel, Efficient Waste Management, Comprehensive Warranty