Description:

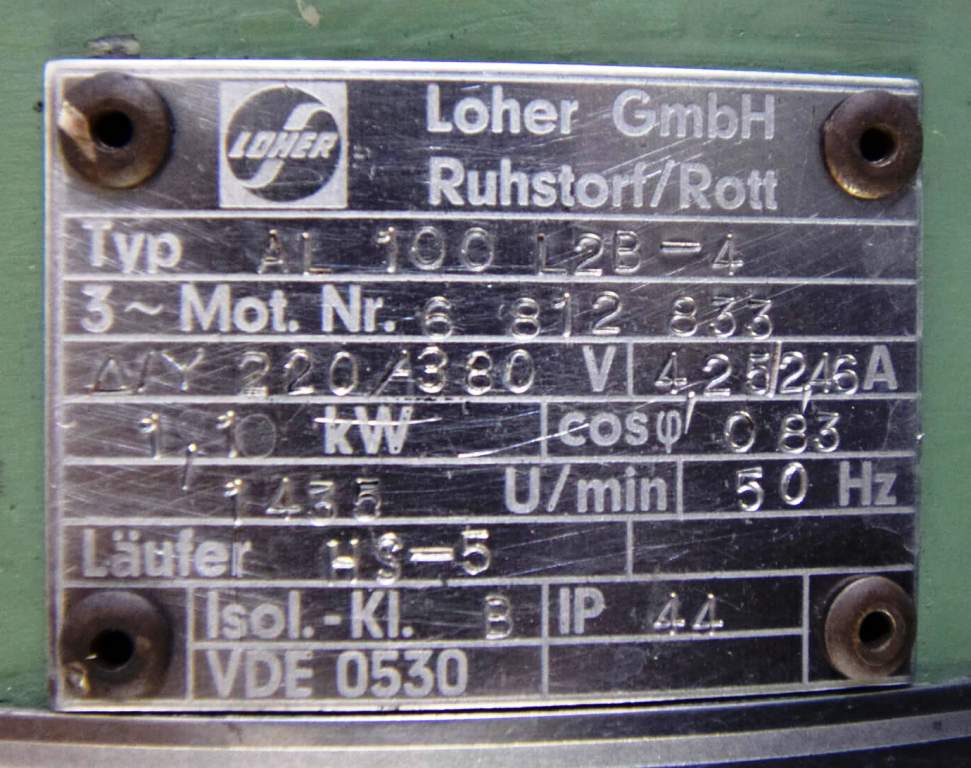

Max bowl speed 10,000 RPM, rated @ 100 GPH, both liquid phases discharged under pressure, 1.1 KW motor 220/380/3/50/1455 RPM, tools and control panel, unitized on a stand. Very good condition. Located in Europe. Equivalent to: SA 1-01-175.

The Westfalia SAOH 205 pilot plant separator, 316SS, is engineered for high-efficiency separation processes, making it an ideal choice for pilot plant applications in various industries, including food processing, pharmaceuticals, and chemical manufacturing. With a maximum bowl speed of 10,000 RPM, this separator ensures rapid and effective separation of liquid phases, achieving a rated capacity of 100 gallons per hour (GPH). The ability to discharge both liquid phases under pressure enhances operational efficiency, reducing the need for additional pumping systems and streamlining the overall process. This feature is particularly advantageous in applications where maintaining product integrity and minimizing contamination is critical.

Equipped with a robust 1.1 KW motor, the Westfalia SAOH 205 operates at a voltage of 220/380 volts and a frequency of 50 Hz, providing reliable performance with a rotational speed of 1455 RPM. The unit comes complete with essential tools and a control panel, all unitized on a sturdy stand, ensuring ease of use and accessibility during operation. The construction of this separator in 316 stainless steel (316SS) not only guarantees durability and resistance to corrosion but also meets stringent hygiene standards required in sensitive processing environments. Its very good condition indicates that it has been well-maintained, making it a valuable addition to any pilot plant setup.

In summary, the Westfalia SAOH 205 pilot plant separator, 316SS, combines high-speed performance with durable construction, making it a reliable solution for efficient liquid separation. Its design facilitates easy maintenance, ensuring that operators can keep the unit running smoothly with minimal downtime. This separator is a versatile tool that can adapt to various processing needs, providing consistent results and enhancing productivity in pilot plant operations.

Key Features:

High-Speed Performance, Durable Construction, Easy Maintenance, Efficient Liquid Discharge, Versatile Applications