Description:

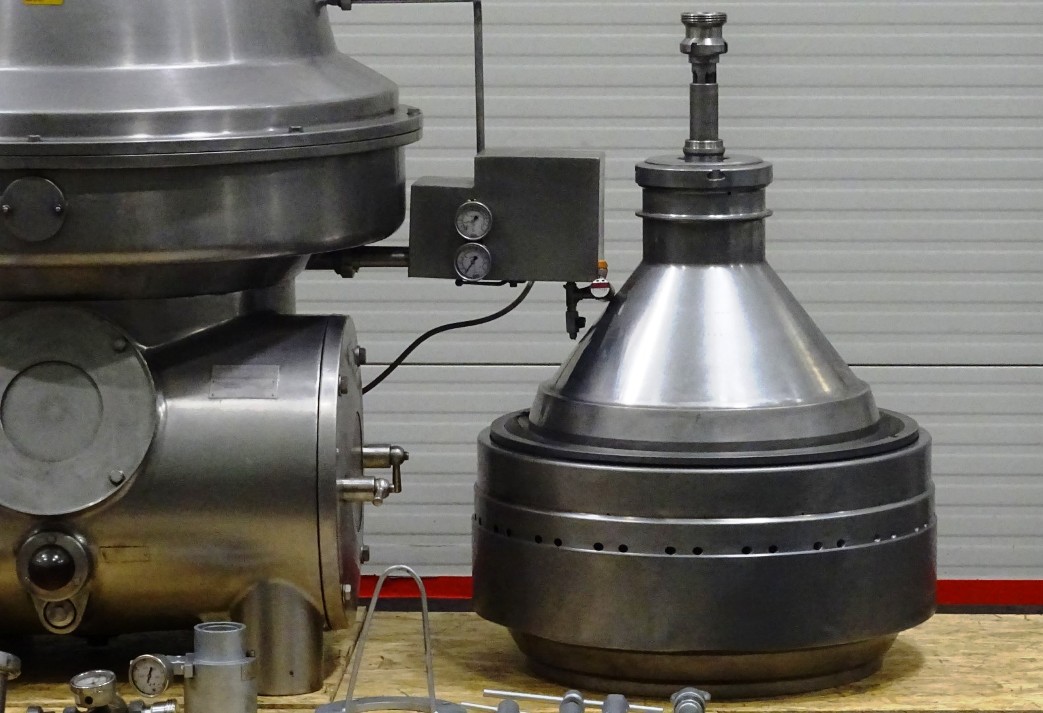

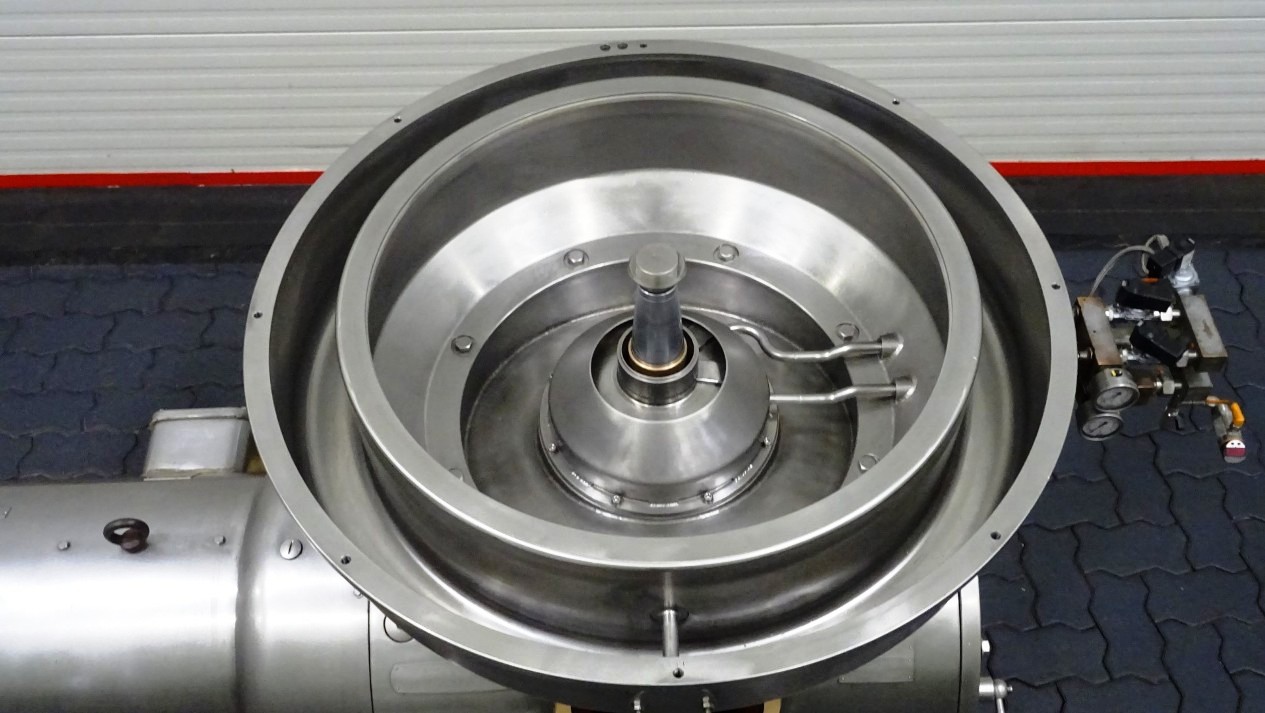

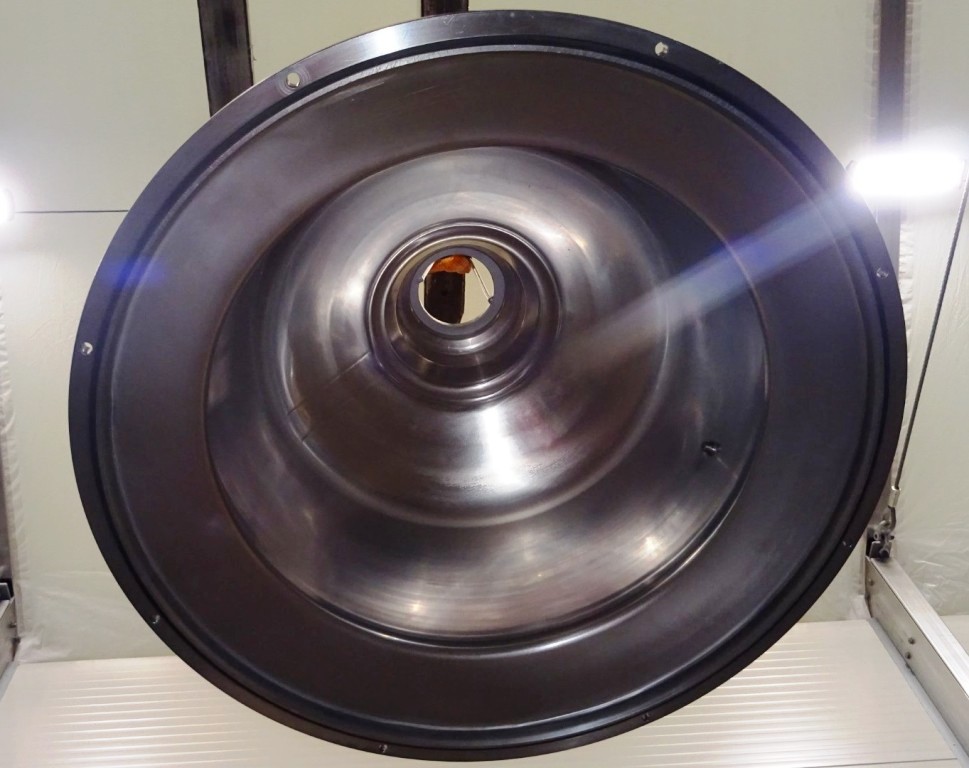

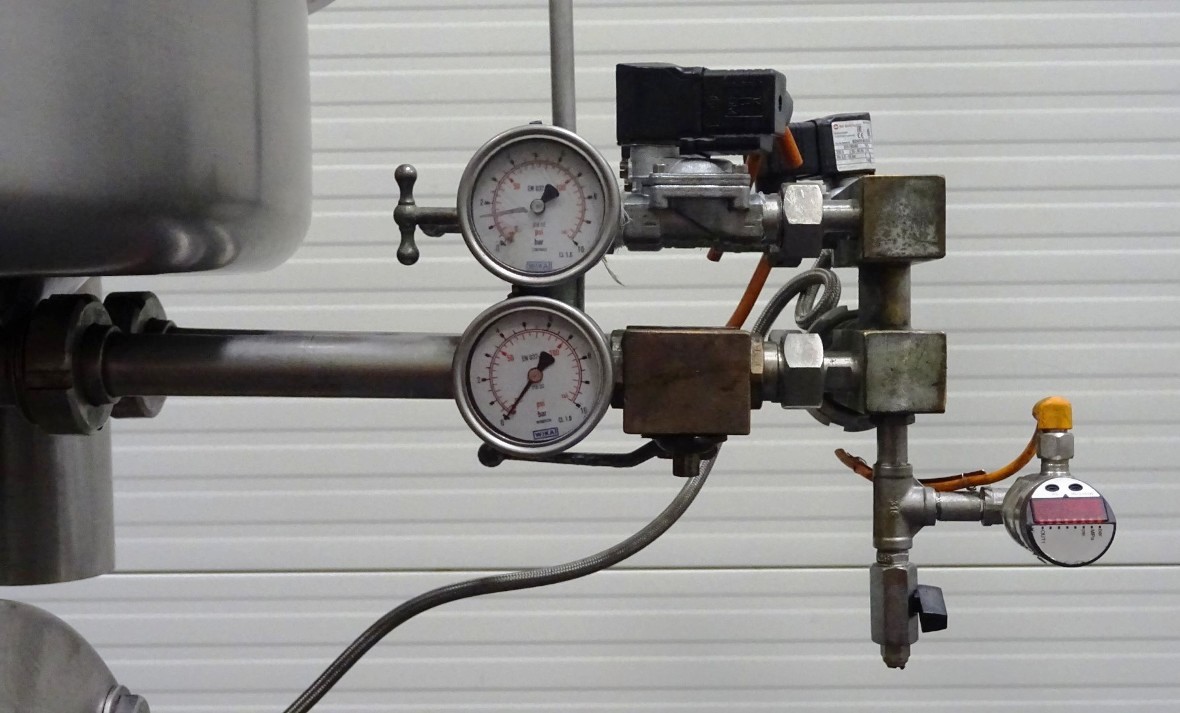

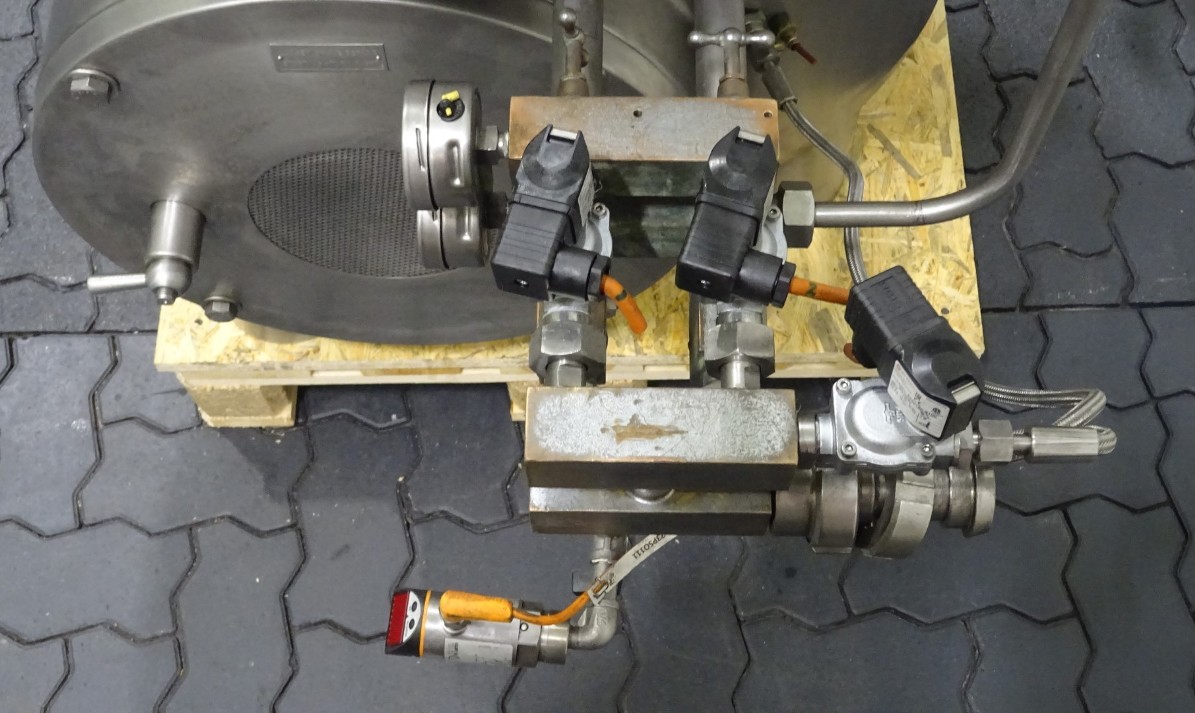

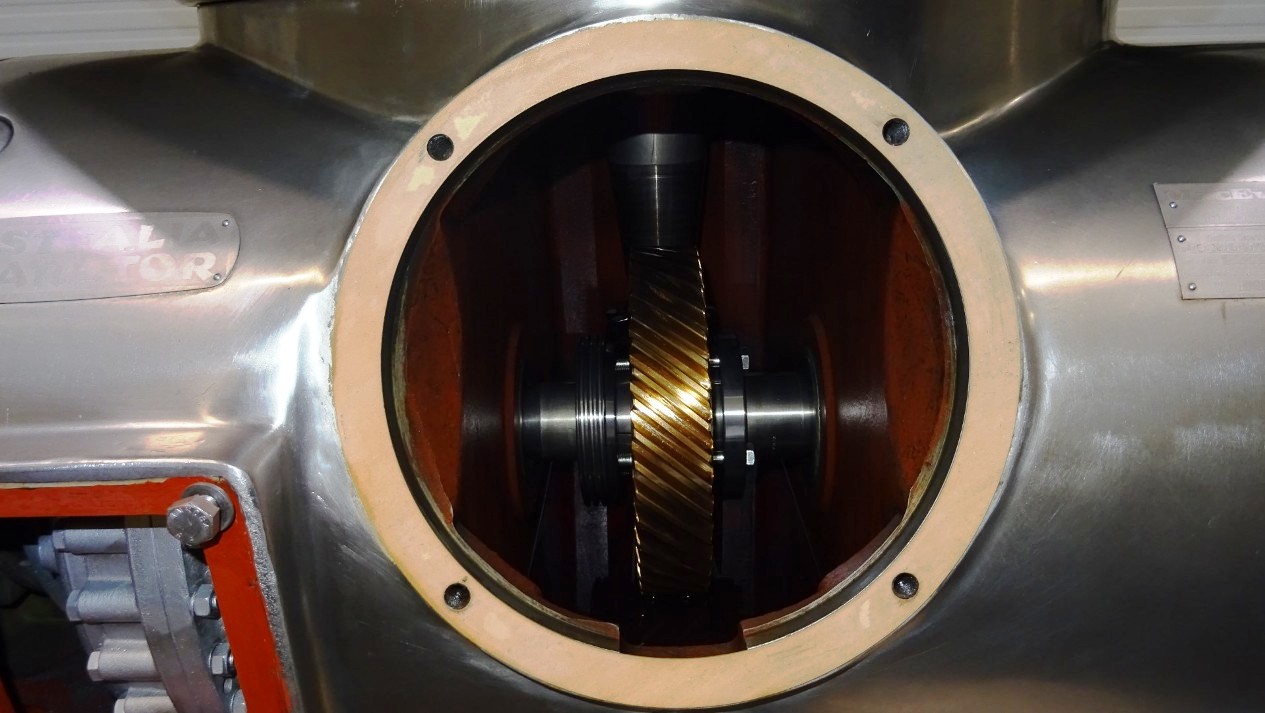

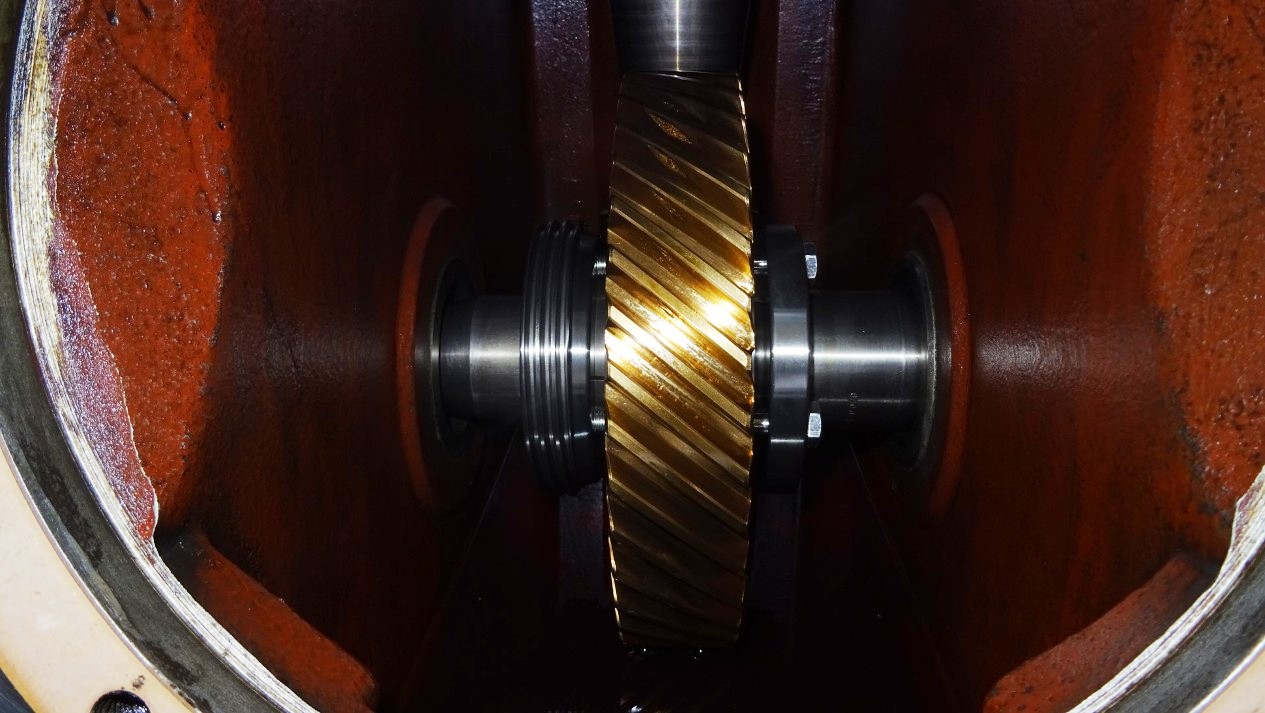

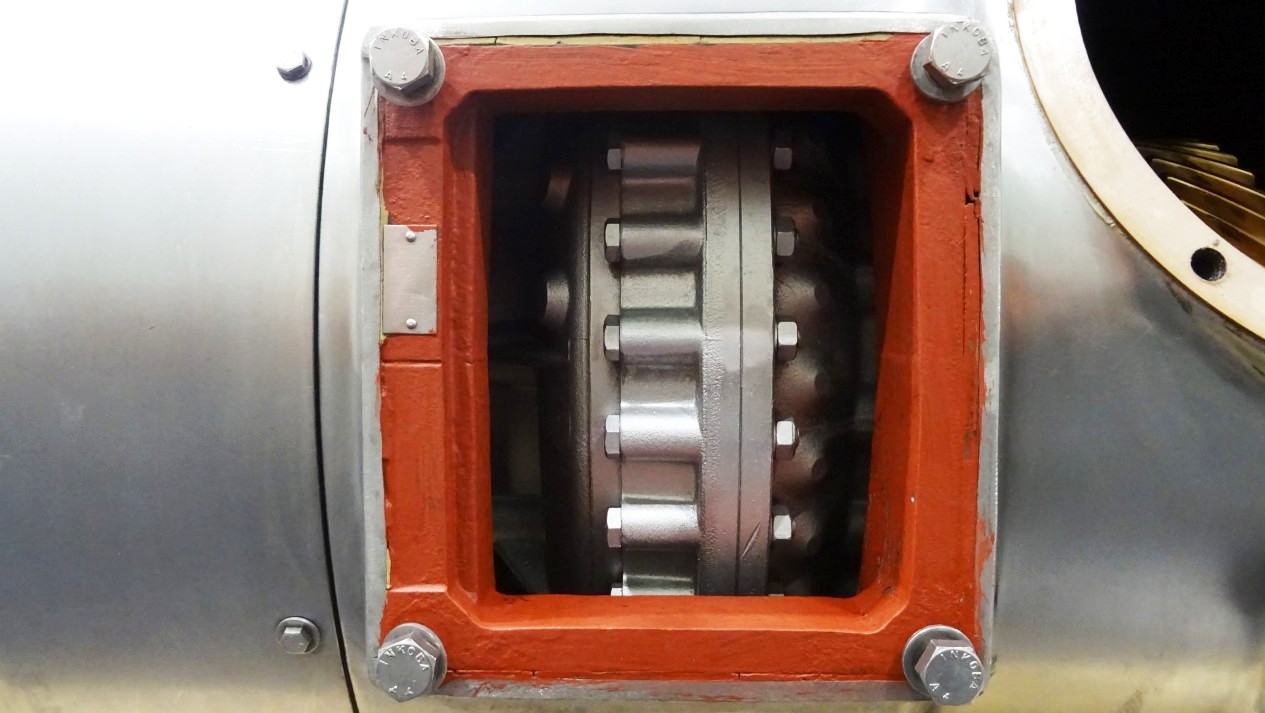

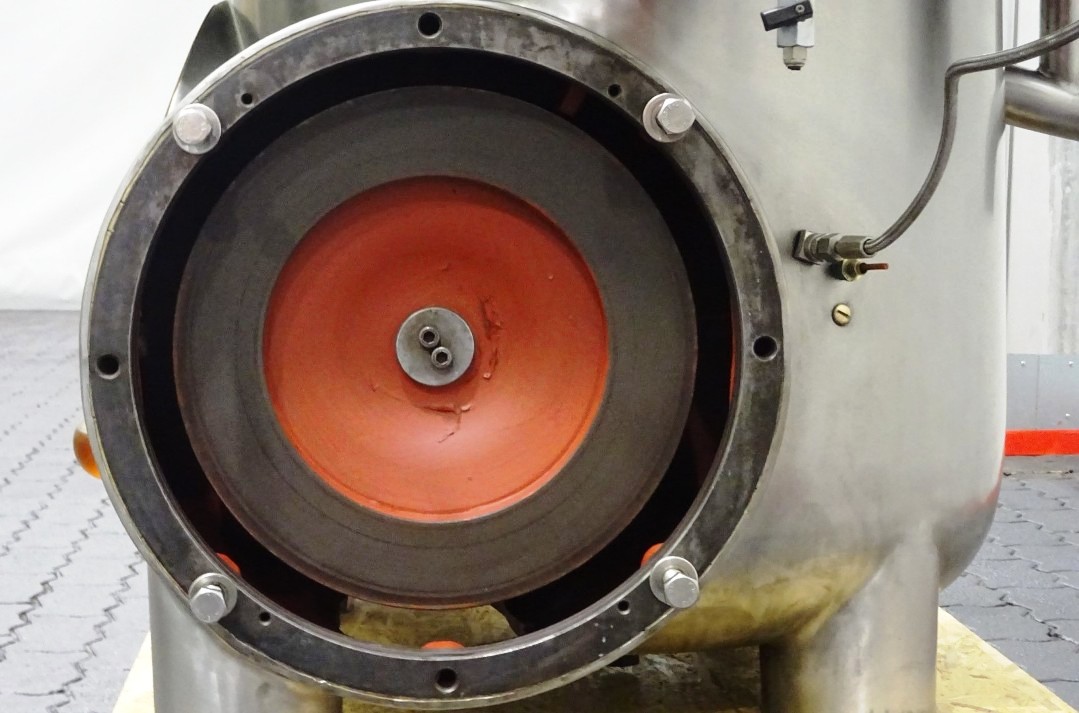

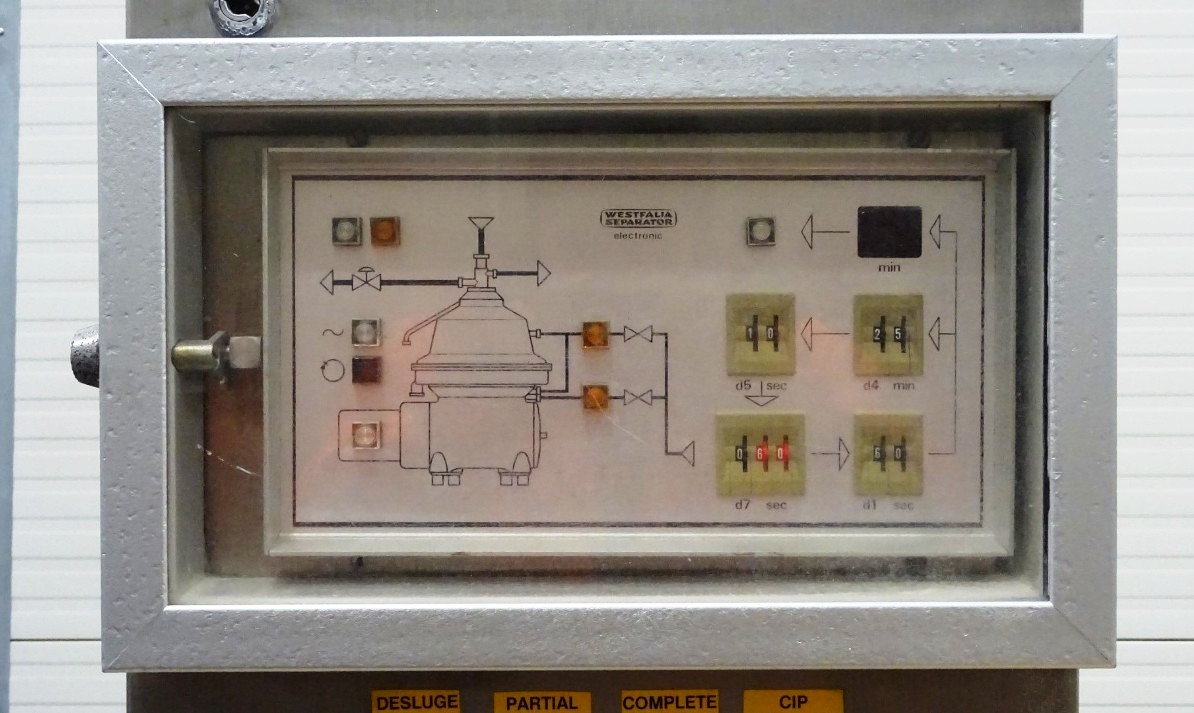

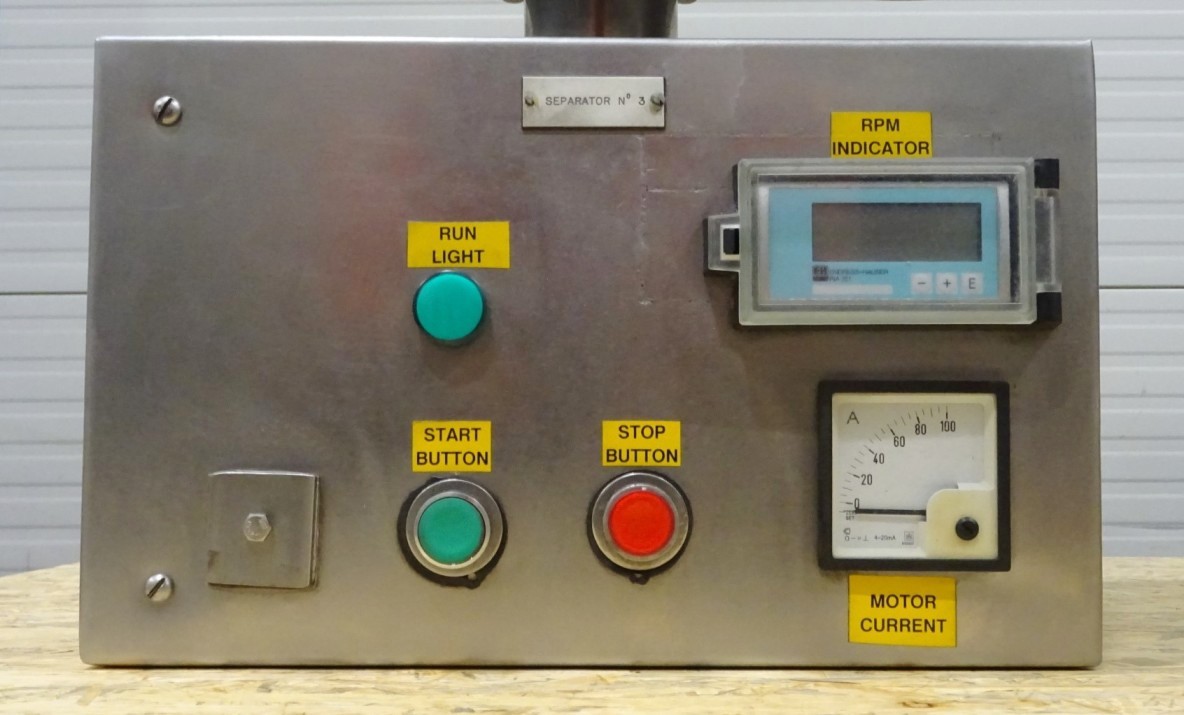

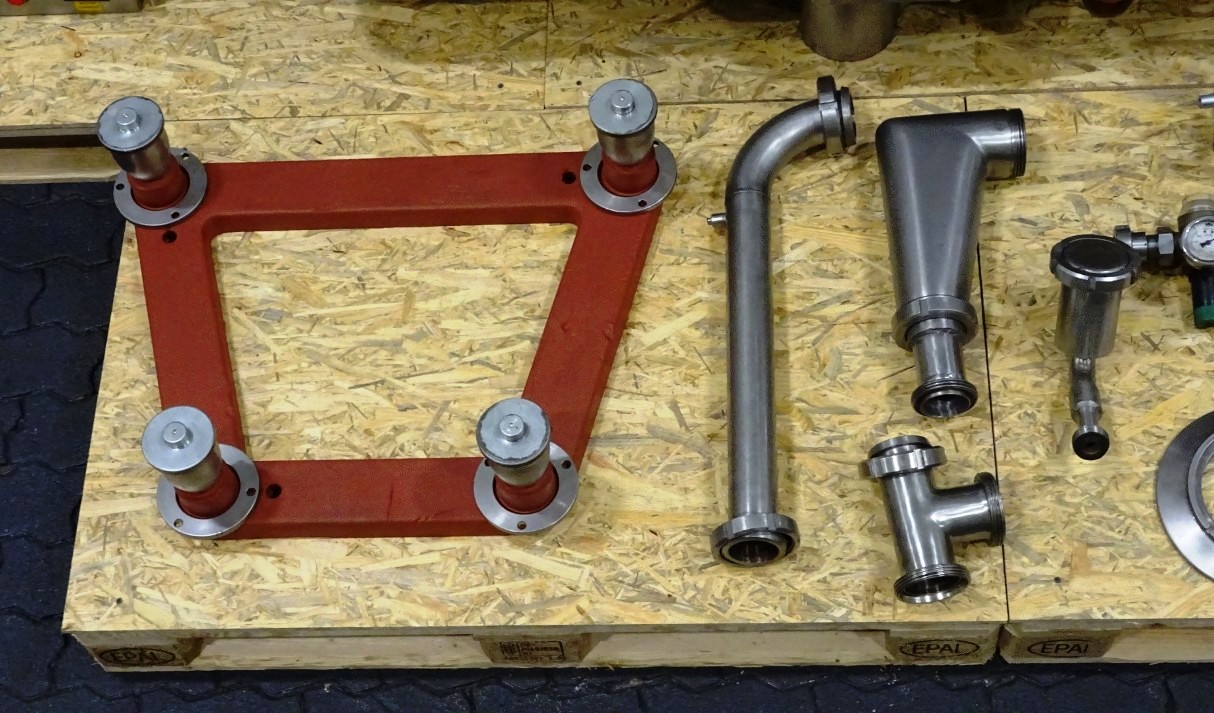

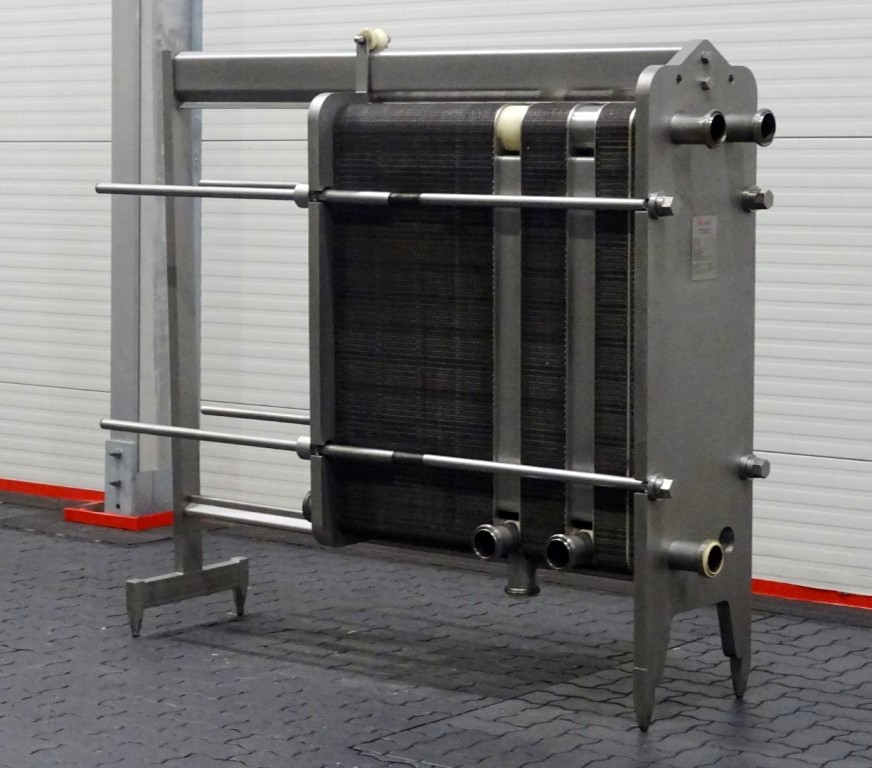

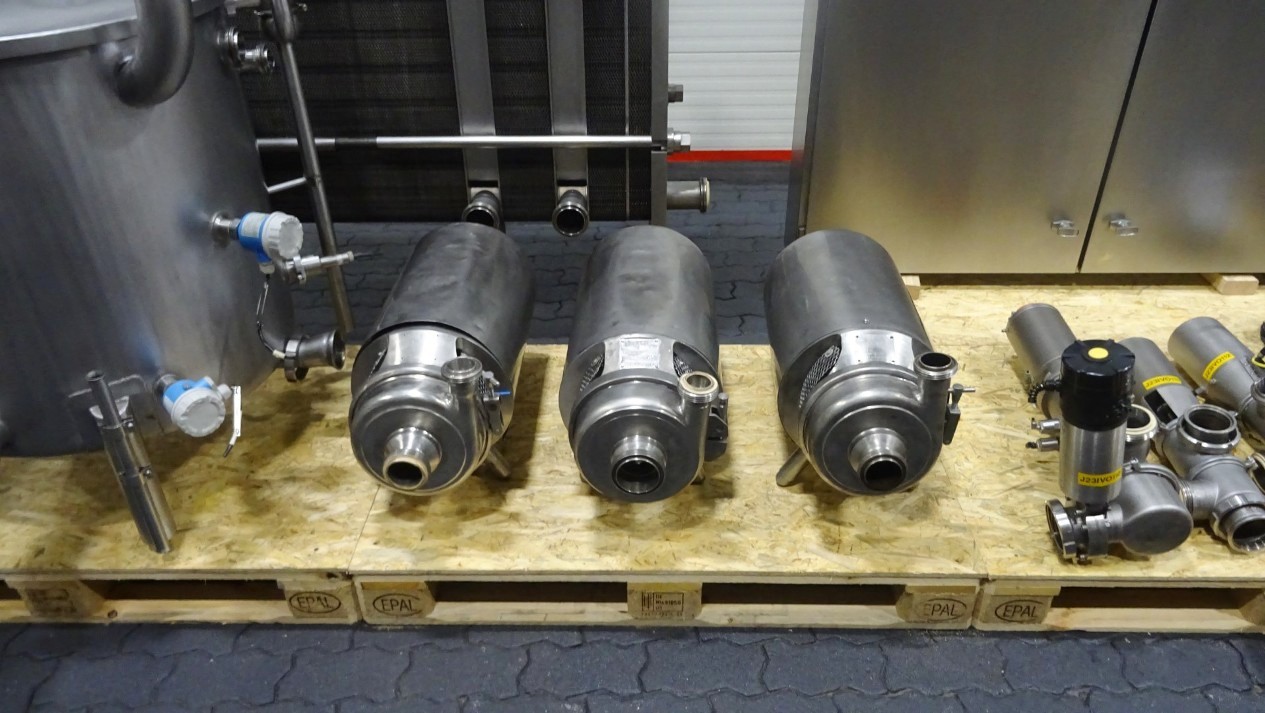

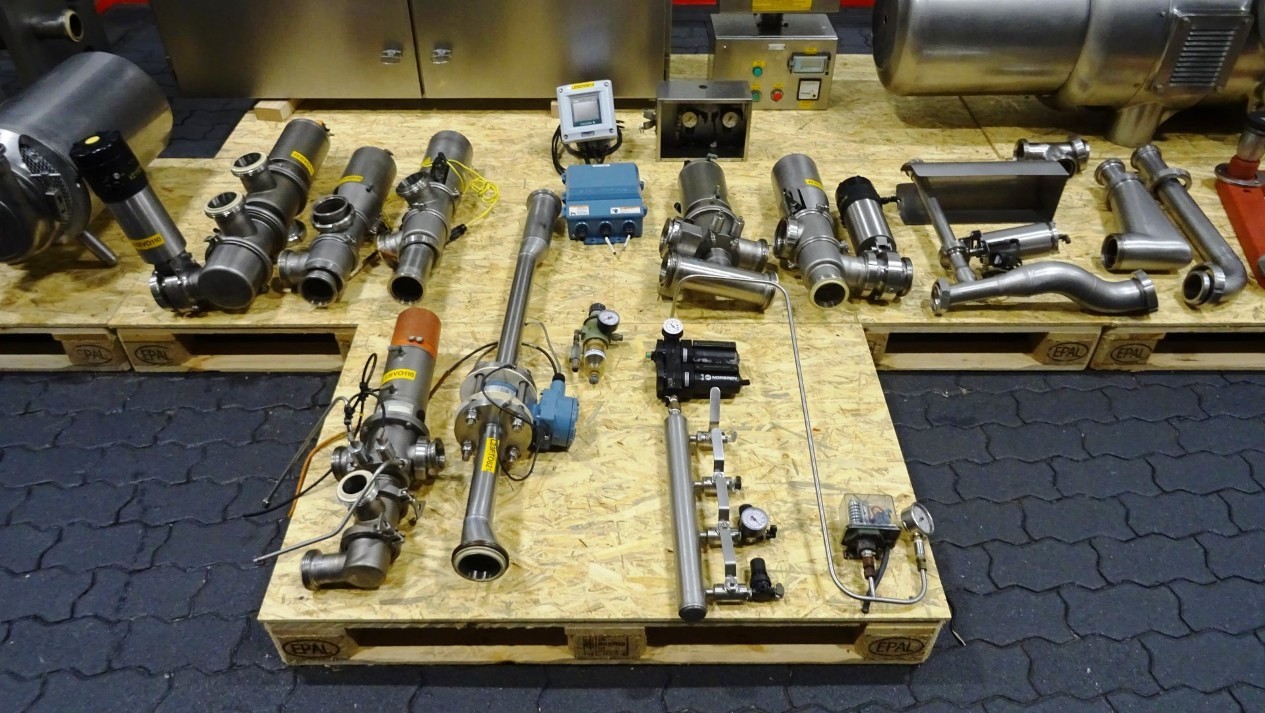

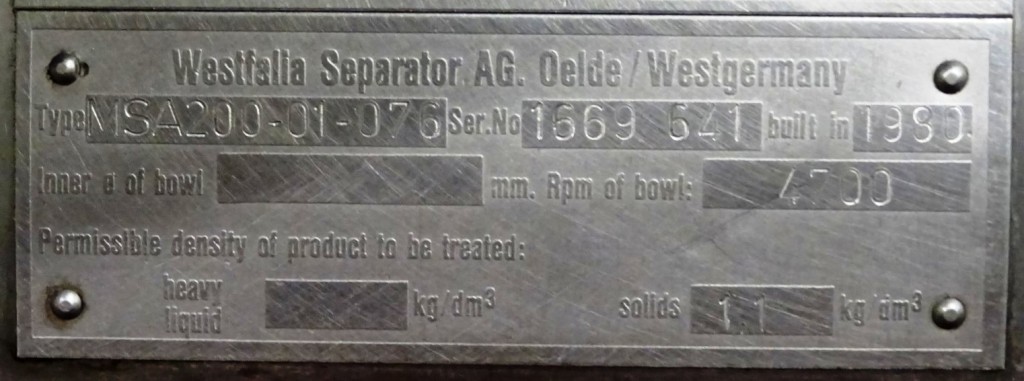

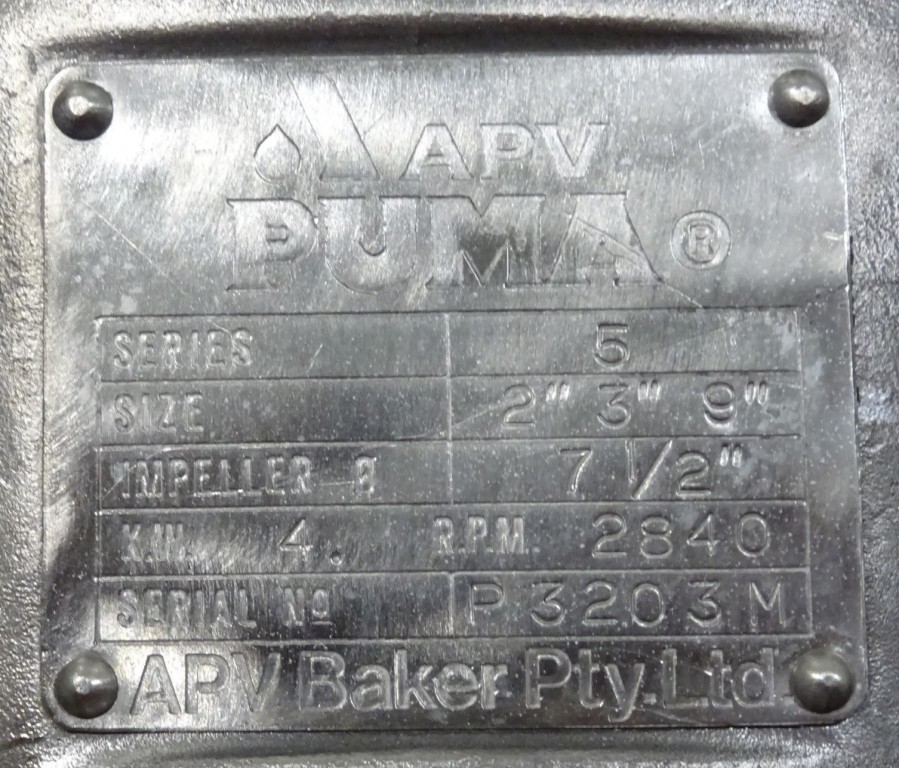

Includes APV N35 RKS plate heat exchanger for milk (4 sections), rated @ 25,000 LPH, 6 bar pressure, 2004 vintage. APV Puma product and booser pumps, Rosemount and Yogakawa digital flow transmitters. Westfalia MSA 200-01-076 milk separator, max bowl speed 4700 RPM, rated @ 25,000 LPH skimming, 37 KW motor 420/3/50/1475 RPM, counter pressure valve on inlet, manometer, manual flow regulation valve and flow indicator for cream, water valves, foundation frame, sludge tank, all inlet/outlet piping, tools and control panel. 1980 vintage. Very good condition. Located in Europe.

The GEA Westfalia 25,000 LPH milk and cream pasteurization plant is engineered for efficiency and reliability, making it an essential asset for dairy processing facilities aiming to maintain high-quality standards. The APV N35 RKS plate heat exchanger, with its four-section design, is specifically optimized for the rapid and effective pasteurization of milk. Operating at a pressure of 6 bar, this unit ensures that the milk is heated uniformly, effectively eliminating harmful pathogens while preserving the nutritional value and flavor of the product. The system's capacity of 25,000 liters per hour positions it as a robust solution for medium to large-scale dairy operations, ensuring that production demands are met without compromising on quality or safety.

Complementing the heat exchanger are the APV Puma product and booster pumps, which facilitate seamless fluid movement throughout the pasteurization process. These pumps are designed for durability and efficiency, ensuring consistent flow rates and pressure management. The integration of advanced digital flow transmitters from Rosemount and Yokogawa enhances process control, allowing operators to monitor flow rates accurately and make real-time adjustments as necessary. Additionally, the Westfalia MSA 200-01-076 milk separator, with a maximum bowl speed of 4700 RPM, plays a crucial role in skimming cream from milk, ensuring optimal fat content in the final product. With a powerful 37 KW motor and various control features such as a counter pressure valve and manual flow regulation valve, this system is designed to deliver superior performance and reliability.

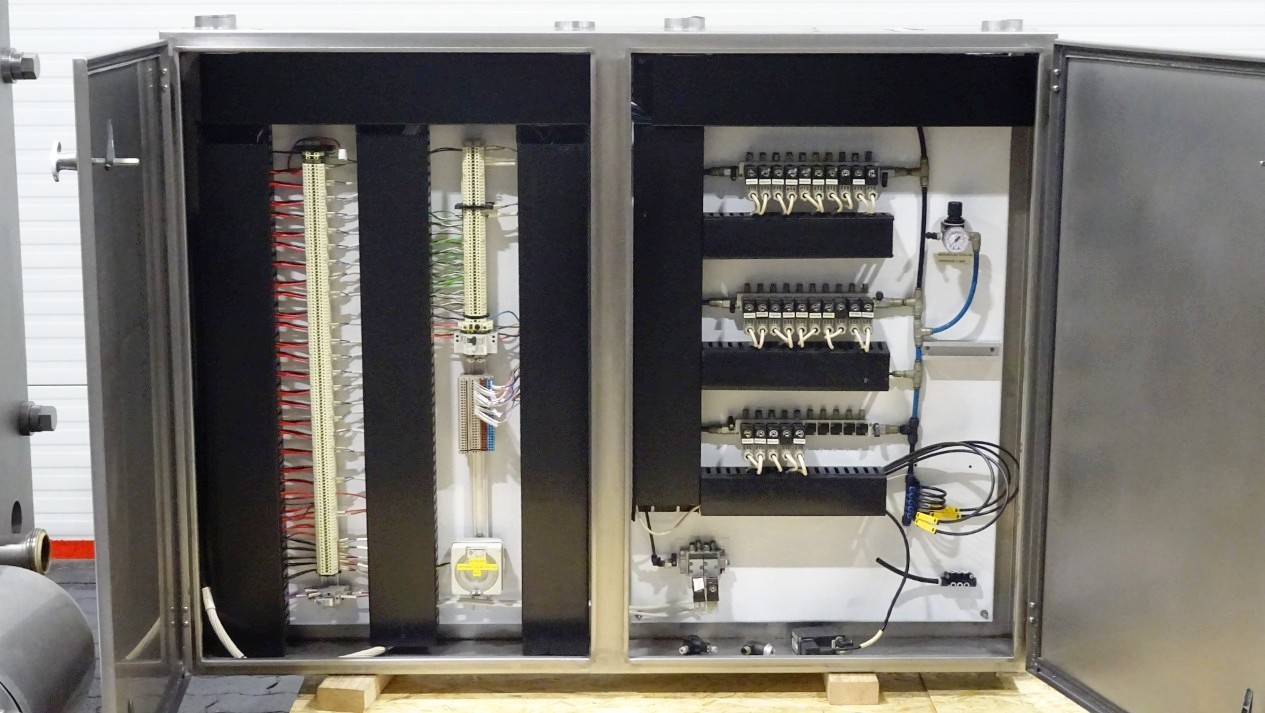

This GEA Westfalia pasteurization plant is not only a testament to advanced engineering but also to the commitment to quality in dairy processing. Its 1980 vintage indicates a legacy of reliability, and its very good condition ensures that it can continue to serve dairy operations effectively. The inclusion of essential components such as a foundation frame, sludge tank, and all necessary inlet and outlet piping means that this plant is ready for installation and operation. With the tools and control panel included, operators will find it easy to manage and maintain the system, making it an excellent investment for any dairy processing facility looking to enhance its production capabilities.

Key Features:

High-Speed Performance, Durable Construction, Advanced Control Systems, Efficient Fluid Movement, Ready for Installation