Description:

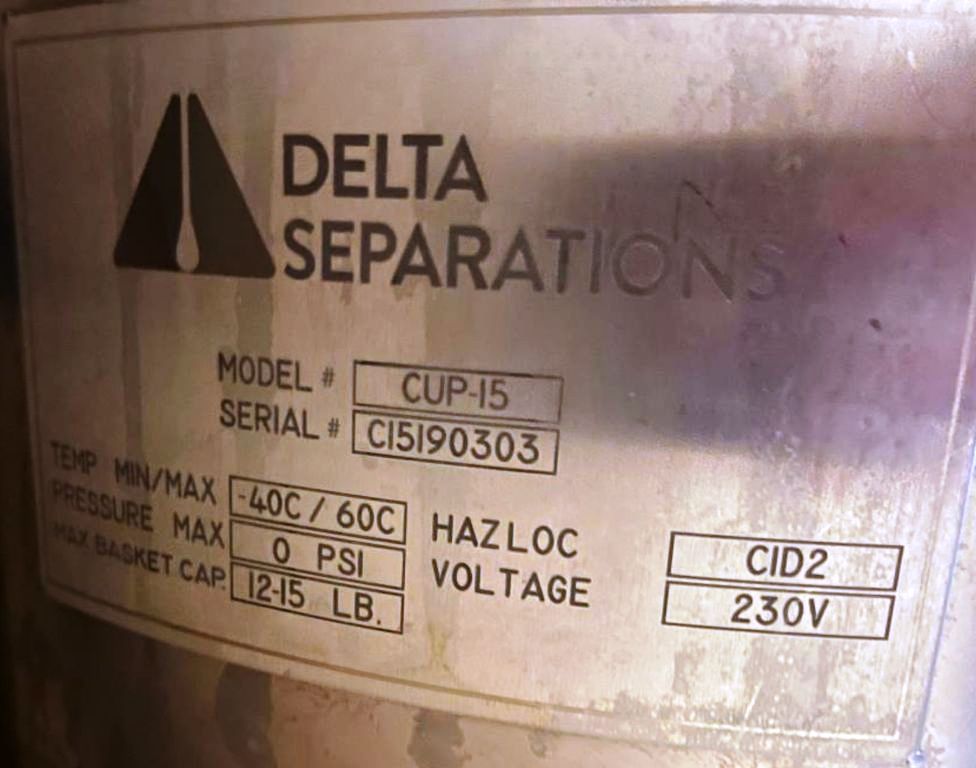

Max bowl speed 1500 RPM, rated @ 15 LB biomass per batch, low temp -40C max, sanitary design, vacuum jacketed insulation layer, 2.2 KW XP motor 230/3/60, reinforced sight glass, tri-clamp fitting for feed and drain ports, Siemens control panel with VFD, mounted on a portable cart. Includes (2) transfer kegs, hoses and adaptors. Excellent condition.

The Delta Separations CUP-15 ethanol extractor, 316L SS. is engineered for efficiency and reliability in the extraction process, making it an ideal choice for laboratories and production facilities seeking to optimize their extraction capabilities. With a maximum bowl speed of 1500 RPM, this extractor is capable of processing up to 15 pounds of biomass per batch, ensuring a robust throughput that meets the demands of high-volume operations. The low-temperature capability of -40°C allows for the extraction of sensitive compounds without degradation, preserving the quality and potency of the extracted materials. The vacuum jacketed insulation layer enhances thermal efficiency, minimizing heat loss and ensuring consistent extraction temperatures throughout the process, which is critical for achieving optimal yields and maintaining product integrity.

Designed with a focus on sanitary operations, the Delta Separations CUP-15 features a reinforced sight glass and tri-clamp fittings for both feed and drain ports, facilitating easy access and maintenance while ensuring a secure and leak-proof connection. The inclusion of a Siemens control panel with variable frequency drive (VFD) allows for precise control over the extraction process, enabling operators to adjust parameters as needed for different types of biomass and desired outcomes. The 2.2 KW explosion-proof motor operates on a 230/3/60 electrical configuration, ensuring powerful performance while adhering to safety standards. Additionally, the extractor is mounted on a portable cart, allowing for easy mobility within the facility, which is particularly beneficial for operations that require flexibility in equipment placement.

To enhance operational efficiency, the Delta Separations CUP-15 comes complete with two transfer kegs, hoses, and adaptors, providing everything needed to streamline the extraction and transfer process. This comprehensive setup not only reduces the time and effort required for setup but also minimizes the risk of contamination during transfers. With its excellent condition and robust construction, this ethanol extractor is a valuable investment for any facility looking to enhance its extraction capabilities while ensuring compliance with industry standards.

Key Features:

High-Speed Performance, Durable Construction, Sanitary Design, Efficient Temperature Control, Portable and User-Friendly