Description:

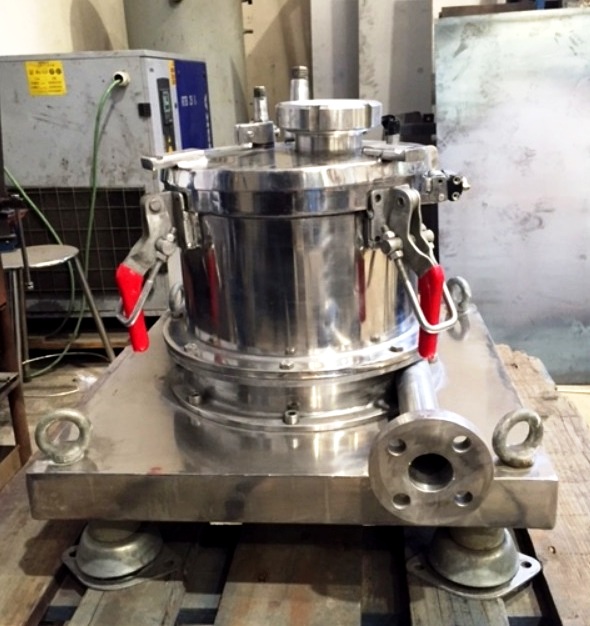

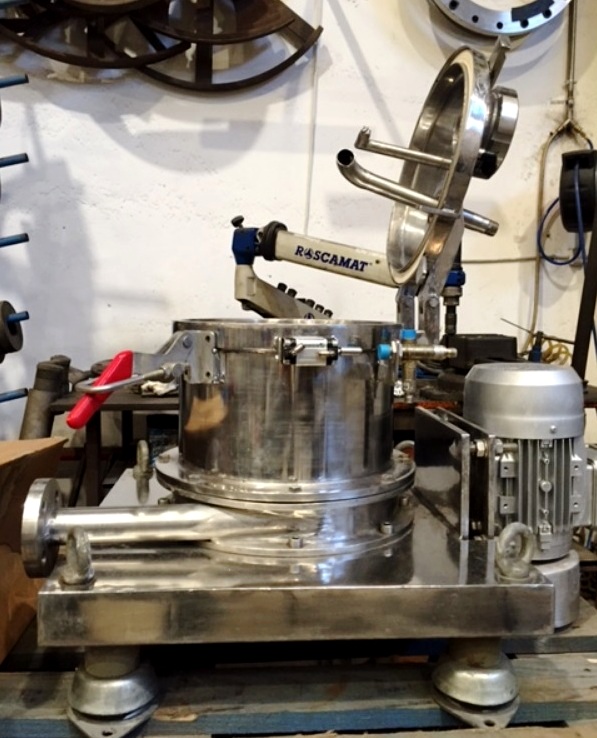

Max bowl speed 3000 RPM, 1500 x G, 320 x 160mm basket ID, 7 L volume, 7 kg max load. Top cover, sight glass, feed rinse tubes, lube system, 1.5 KW motor 220/380/3/50/60 and VFD control panel unitized on a skid. 2010 vintage. Reconditioned to "as new." Located in Europe.

The (2) Comteifa DT-2-BD perforate basket centrifuges, 316L SS, are engineered for high-performance separation processes, making them an ideal choice for various industrial applications. With a maximum bowl speed of 3000 RPM and a gravitational force of 1500 x G, these centrifuges excel in efficiently separating solids from liquids. The 320 x 160mm basket interior is designed to accommodate a volume of 7 liters, allowing for a maximum load of 7 kg, which is suitable for moderate to large batch processing. The robust construction using 316L stainless steel ensures durability and resistance to corrosion, making these centrifuges particularly well-suited for applications in the pharmaceutical, chemical, and food processing industries where hygiene and material integrity are paramount.

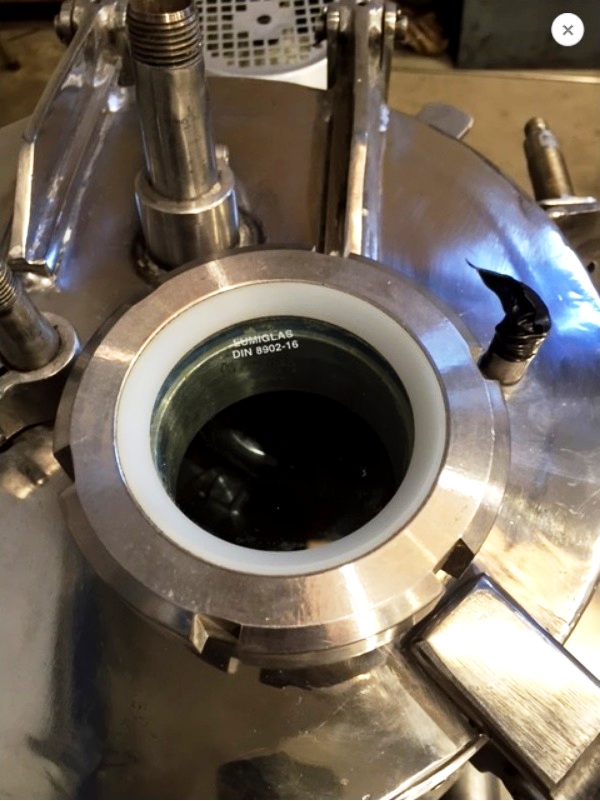

Equipped with a top cover, sight glass, and feed rinse tubes, the (2) Comteifa DT-2-BD centrifuges provide enhanced operational visibility and ease of use. The integrated lubrication system ensures smooth operation and longevity of the motor, while the 1.5 KW motor, compatible with 220/380V, 3-phase, 50/60 Hz power supply, delivers reliable performance. The inclusion of a Variable Frequency Drive (VFD) control panel allows for precise speed adjustments, optimizing the centrifuge's performance for different materials and operational requirements. These units have been reconditioned to 'as new' standards, ensuring that they meet the rigorous demands of industrial applications while providing a cost-effective solution for buyers looking to enhance their separation capabilities.

Located in Europe, these centrifuges are not only a testament to quality engineering but also offer a practical solution for businesses seeking to upgrade their existing equipment without the burden of new machinery costs. The reconditioning process has ensured that these units are fully functional and ready for immediate use, making them an attractive option for companies looking to improve their operational efficiency and productivity.

Key Features:

High-Speed Performance, Durable Construction, Easy Maintenance, Versatile Applications, Reconditioned to 'As New'