Description:

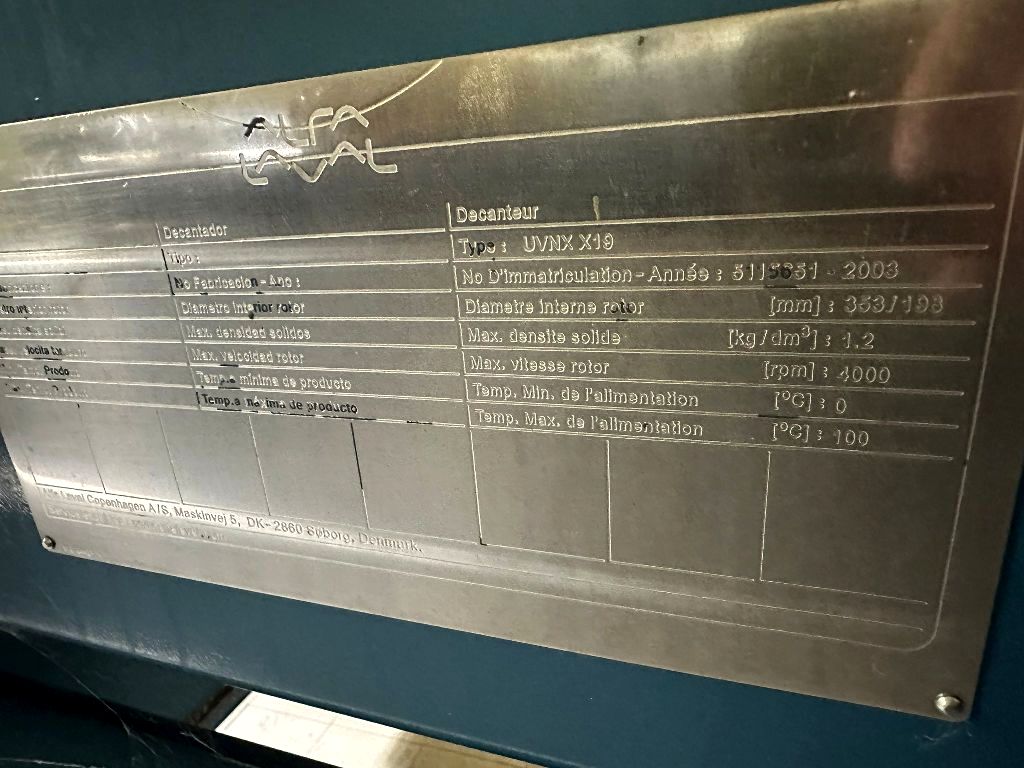

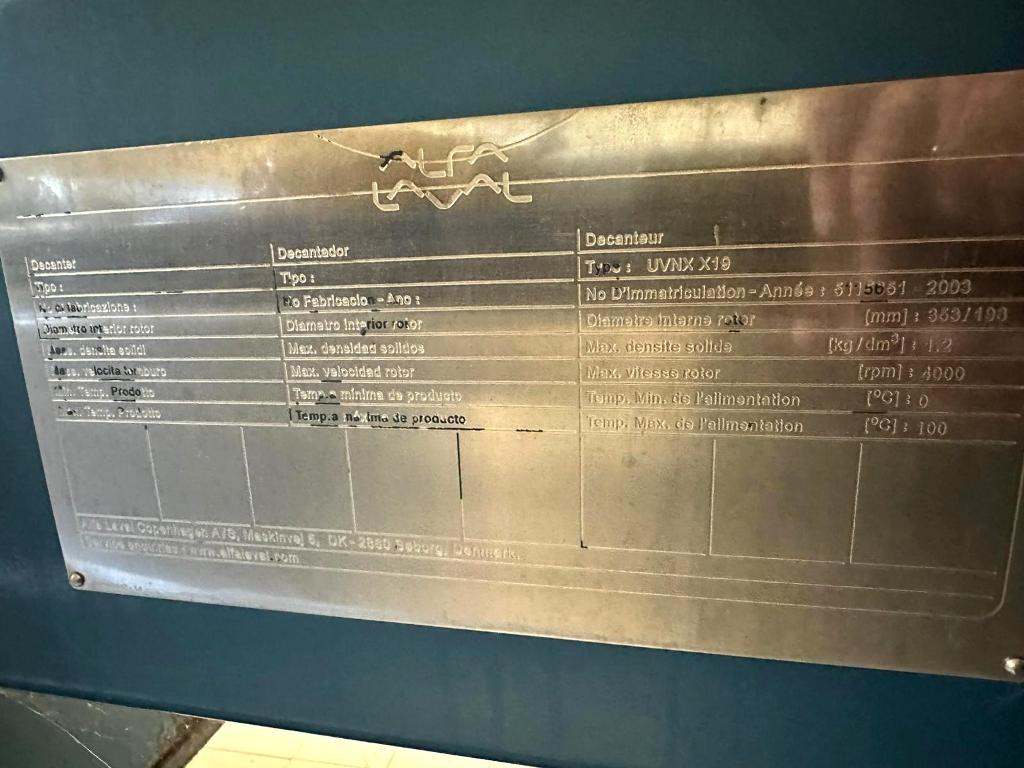

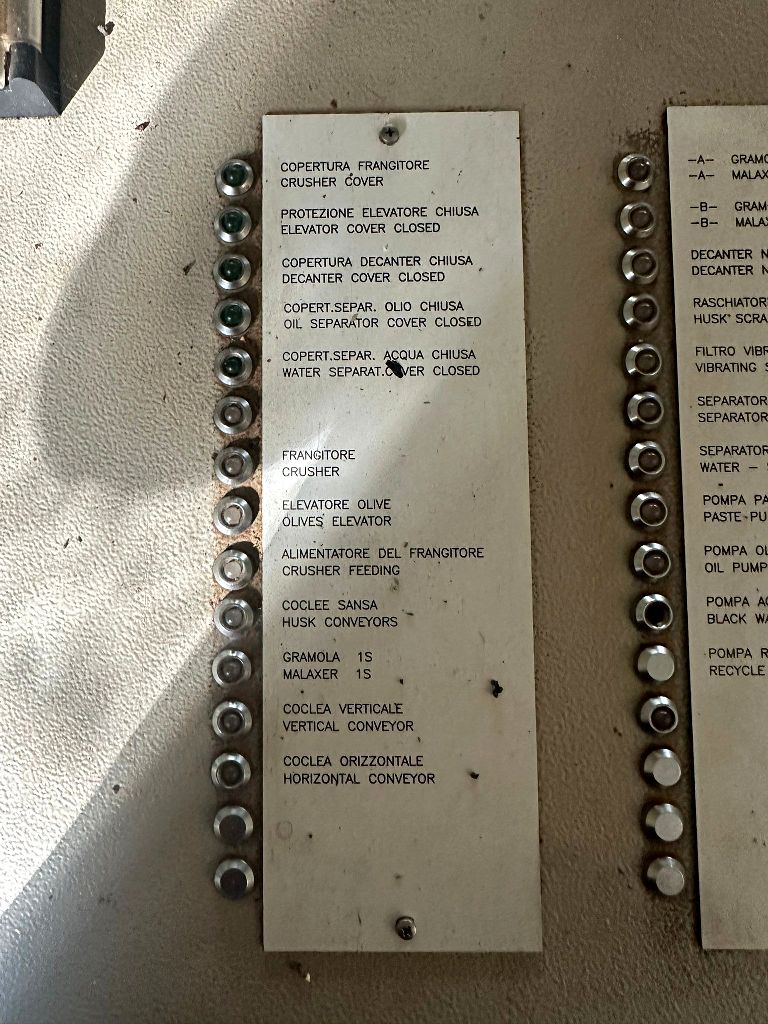

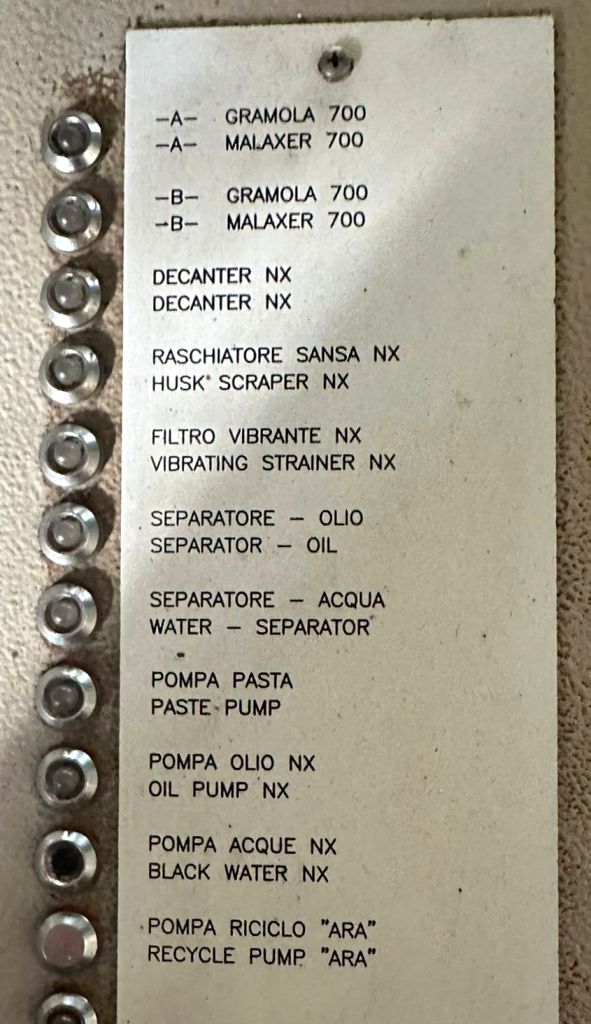

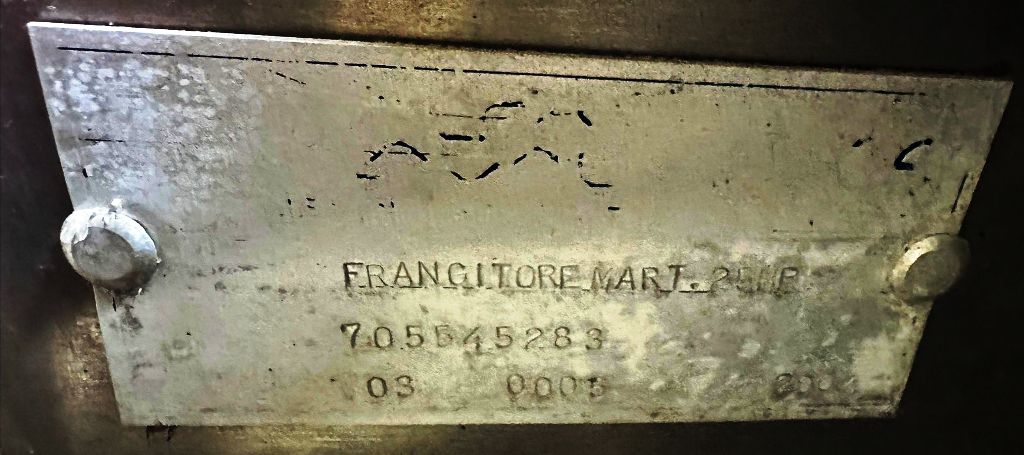

Max bowl speed 4000 RPM, 3158 x G, oil phase discharged under pressure, 70mm single lead hardsurfaced Esbjerg conveyor, 22 KW motor 380/3/50/1450 RPM, 159:1 2.5 kNm gearbox, 12.5 KW backdrive, guards, feed tube, vibration switch/isolators and chutes, unitized on stand. Includes (2) 700 LPH malaxers, husk scraper, vibrating strainer, oil separator, water separator, paste pump, oil pump, black water and recycle pumps, crusher, conveyors, olive elevator and PLC control panel. 2003 vintage. Very good condition. Located in Europe. Same as UVNX 418S-11G.

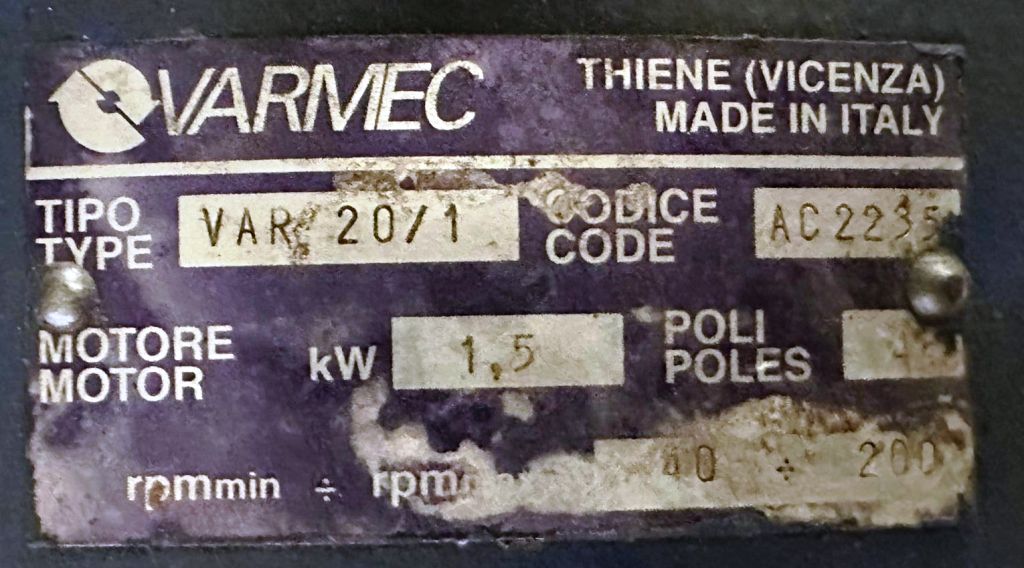

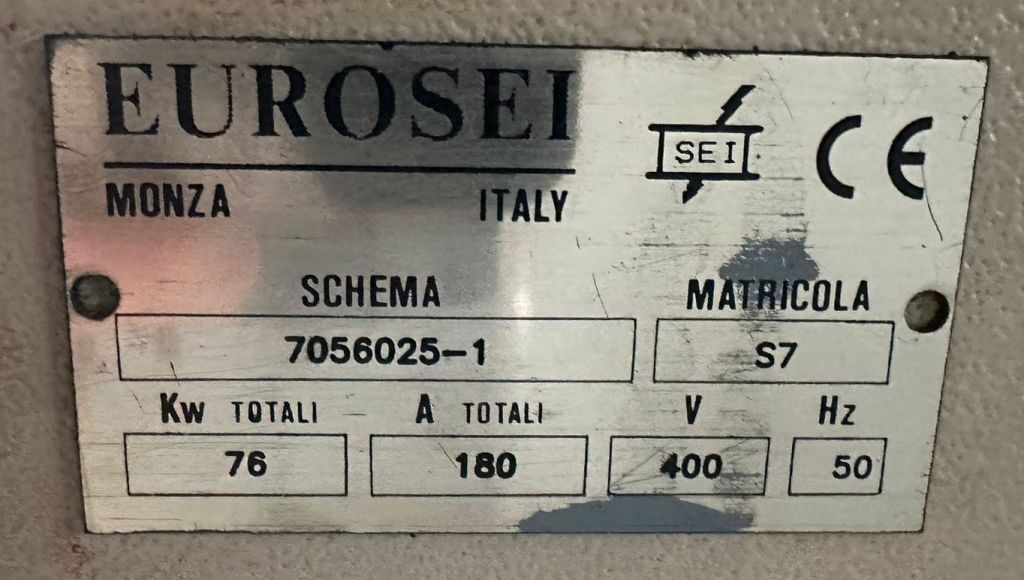

The Alfa-Laval X19 tricanter centrifuge olive oil plant is engineered to optimize the extraction process of olive oil, ensuring maximum yield and quality. With a maximum bowl speed of 4000 RPM and a force of 3158 x G, this unit efficiently separates the oil phase under pressure, enhancing the overall productivity of the olive oil production line. The inclusion of a 70mm single lead hardsurfaced Esbjerg conveyor ensures that the solid and liquid phases are effectively transported without compromising the integrity of the olive oil. The robust 22 KW motor, operating at 380/3/50/1450 RPM, coupled with a 159:1 2.5 kNm gearbox, provides the necessary power and torque to handle the demanding requirements of continuous operation in an industrial setting. Additionally, the 12.5 KW backdrive enhances the system's efficiency by allowing for optimal control during the extraction process.

This comprehensive plant setup is designed with user convenience and safety in mind. It includes essential components such as guards, a feed tube, vibration switch/isolators, and chutes, all of which contribute to a safe working environment. The unitized design on a stand facilitates easy installation and maintenance, making it an ideal choice for both new and established olive oil producers. The Alfa-Laval X19 tricanter centrifuge olive oil plant also comes equipped with two 700 LPH malaxers, a husk scraper, a vibrating strainer, and both oil and water separators, ensuring a streamlined workflow. The inclusion of a paste pump, oil pump, black water and recycle pumps, a crusher, conveyors, and an olive elevator further enhances the plant's operational capabilities. With a PLC control panel, operators can easily monitor and adjust the system parameters, ensuring optimal performance. This 2003 vintage unit is in very good condition and is located in Europe, making it a valuable asset for any olive oil production facility.

Key Features:

High-Speed Performance, Durable Construction, Comprehensive Plant Setup, User-Friendly Control Panel, Efficient Separation Process