Description:

Max bowl speed 4000 RPM, 3180 x G, adjustable liquid dams, wear liners on feed zone and cake ports, 110mm single lead STC tiled conveyor, 18.5 KW motor 400/3/50/3000 RPM, 159:1 2.5 kNm gearbox, feed tube, guards, vibration switch/isolators, grease lubricated bearings and chutes unitized on stand. Reconditioned. Located in Europe.

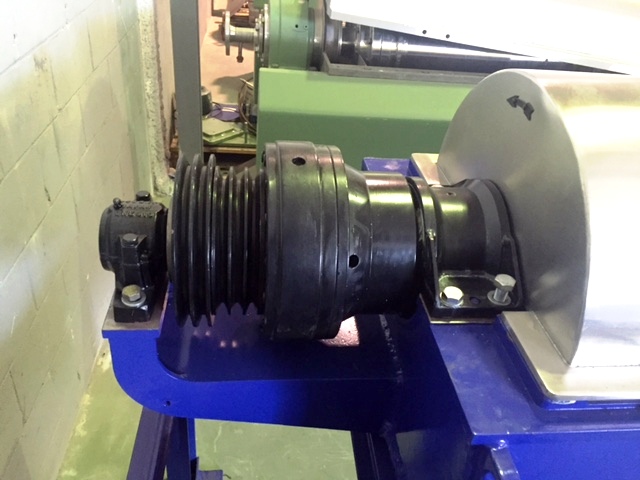

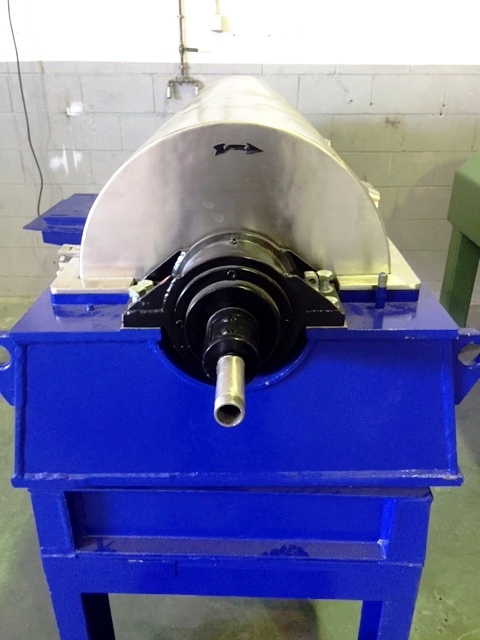

The Alfa-Laval NX 418B-31G decanter centrifuge, 316SS, is engineered for high-performance separation processes, making it an ideal choice for various industrial applications. With a maximum bowl speed of 4000 RPM and a centrifugal force of 3180 x G, this decanter centrifuge efficiently separates solids from liquids, ensuring optimal product quality and recovery rates. The adjustable liquid dams allow for precise control over the separation process, accommodating different feed characteristics and enhancing operational flexibility. Additionally, the wear liners on the feed zone and cake ports extend the lifespan of critical components, reducing maintenance costs and downtime.

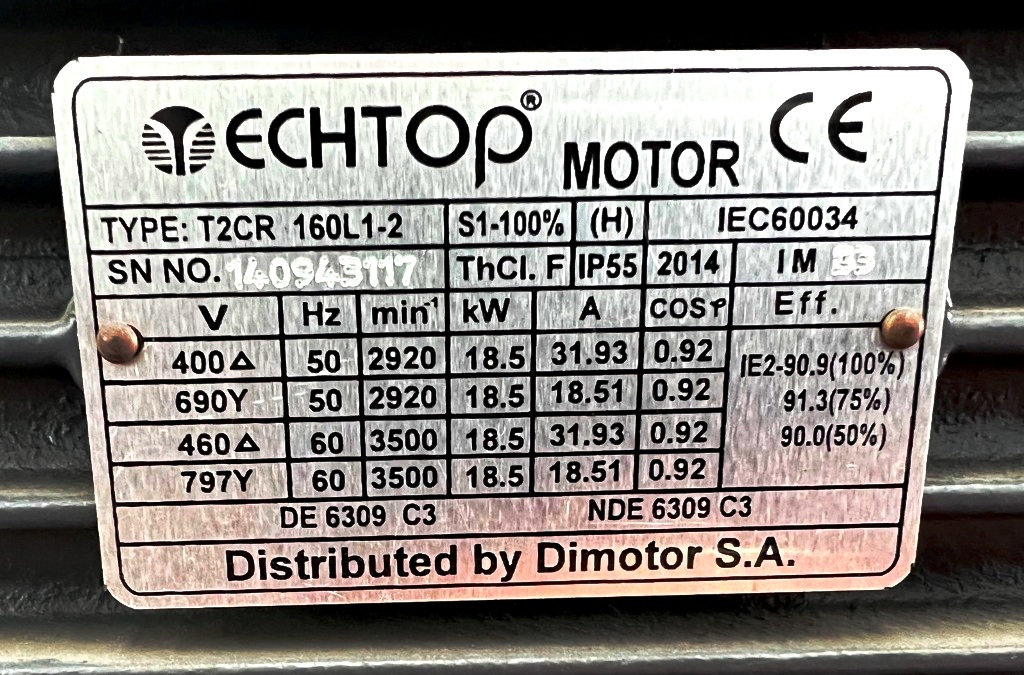

Equipped with a robust 18.5 KW motor operating at 400/3/50/3000 RPM, the Alfa-Laval NX 418B-31G decanter centrifuge delivers reliable performance under demanding conditions. The 159:1 2.5 kNm gearbox ensures smooth operation and efficient torque transmission, while the 110mm single lead STC tiled conveyor facilitates effective cake discharge. Safety and reliability are paramount, as evidenced by the inclusion of vibration switch/isolators and grease-lubricated bearings, which minimize wear and enhance the longevity of the equipment. This reconditioned unit is located in Europe, making it a valuable addition for businesses looking to optimize their separation processes without the expense of new equipment.

Key Features:

High-Speed Performance, Durable Construction, Adjustable Liquid Dams, Efficient Cake Discharge, Low Maintenance Requirements