Description:

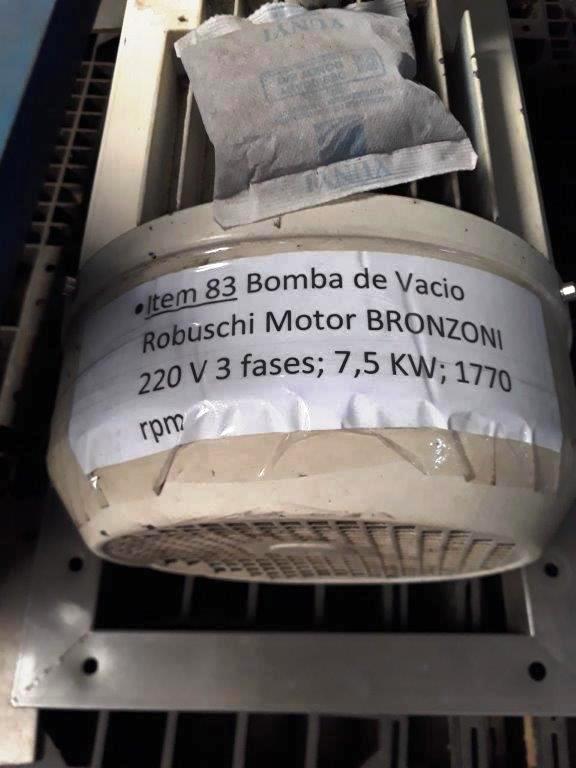

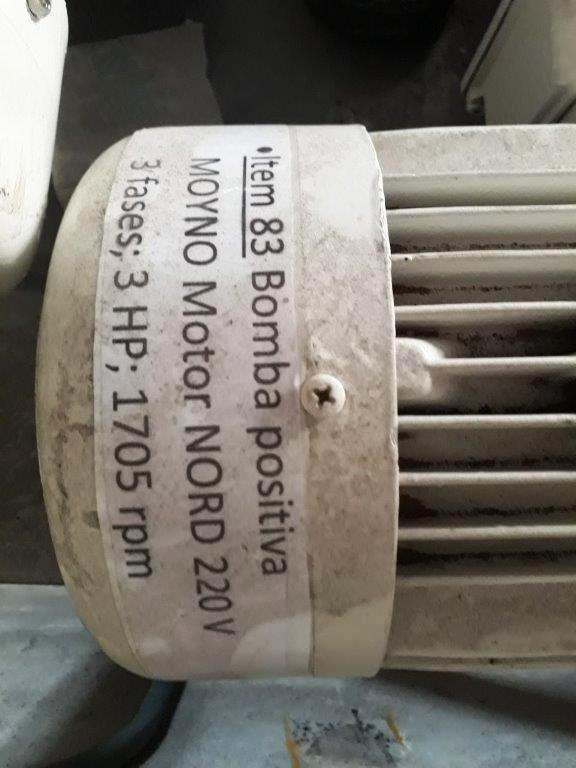

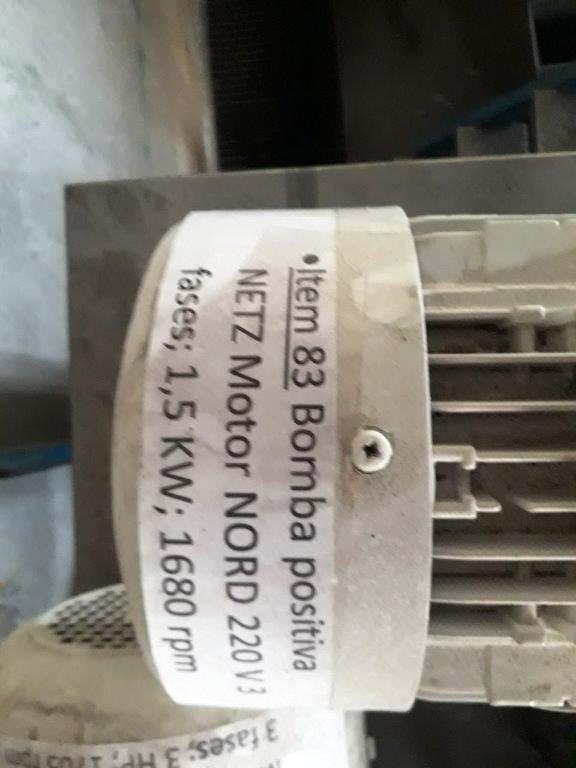

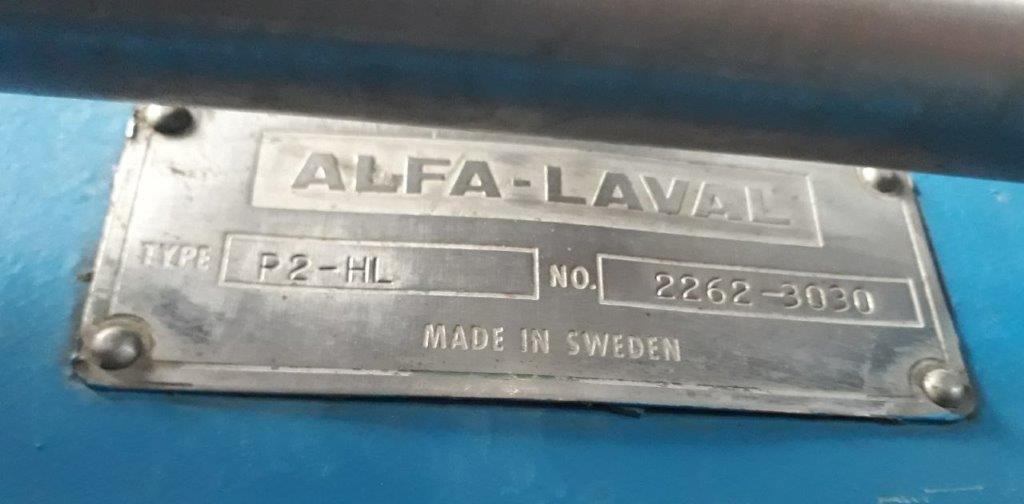

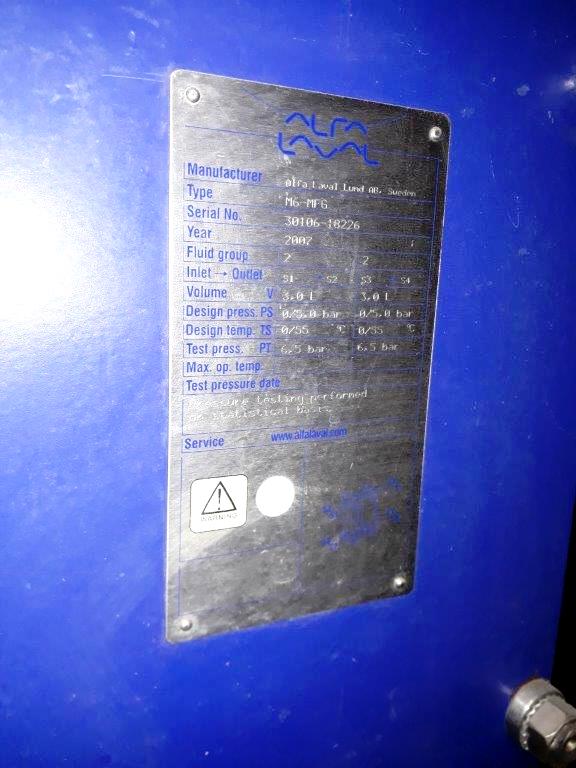

Thin-film, single-effect, spinning cone evaporator designed for highly viscous slurry to 20,000cP. Rated @ 800 LPH (12-65 Brix). Includes 3 column pre-evaporator and tower, A/L P2-HL plate heat exchanger, Wide Stream FRONTS-WSFRM PHE rated @ 194.4 L, 7.0 Bar & -10/120C, M6-MFG PHE rated @ 3.0 L, 5 Bar & 0-55C, 3 HP Moyno progressive cavity pump, 7.5 HP vacuum pump, strainer, level regulator thermometer and feed pump. No controls. Very good condition. Located in South America.

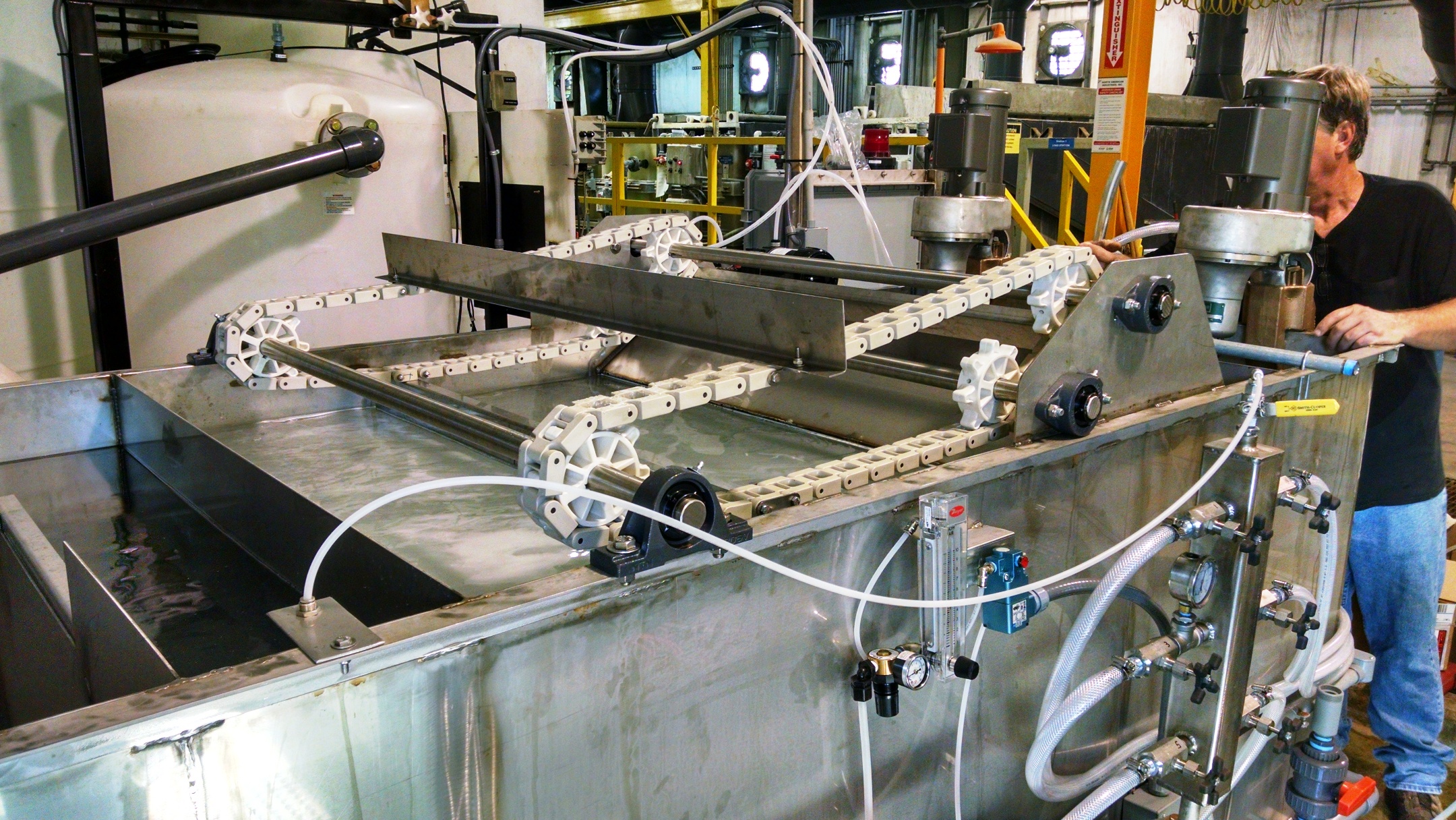

The Alfa-Laval CT-6 Centritherm evaporator, 316SS, is engineered to efficiently handle highly viscous slurries, making it an ideal choice for industries that require precise concentration processes. With a maximum viscosity of 20,000 cP, this thin-film, single-effect evaporator excels in applications where traditional evaporators may struggle. The design incorporates a spinning cone mechanism that promotes rapid evaporation while minimizing thermal degradation of sensitive materials. Rated at 800 liters per hour (LPH) and capable of achieving Brix levels between 12 and 65, this equipment is particularly suited for food processing, pharmaceuticals, and chemical manufacturing, where product integrity and concentration accuracy are paramount.

The Alfa-Laval CT-6 features a robust construction, utilizing 316 stainless steel, which ensures durability and resistance to corrosion, even in demanding environments. The system includes a three-column pre-evaporator and a tower that work in tandem to optimize the evaporation process. The integration of an A/L P2-HL plate heat exchanger and a Wide Stream FRONTS-WSFRM PHE rated at 194.4 L and 7.0 Bar enhances thermal efficiency, allowing for effective heat transfer and energy savings. Additionally, the system is equipped with a 3 HP Moyno progressive cavity pump and a 7.5 HP vacuum pump, which facilitate smooth operation and consistent feed flow. With the inclusion of a strainer, level regulator, thermometer, and feed pump, this evaporator is designed for seamless integration into existing production lines, although it should be noted that controls are not included. This unit is in very good condition and is currently located in South America, ready for immediate deployment in your facility.

Key Features:

High Viscosity Handling, Efficient Heat Transfer, Durable Stainless Steel Construction, Integrated Pumping System, Optimized for Energy Savings