Description:

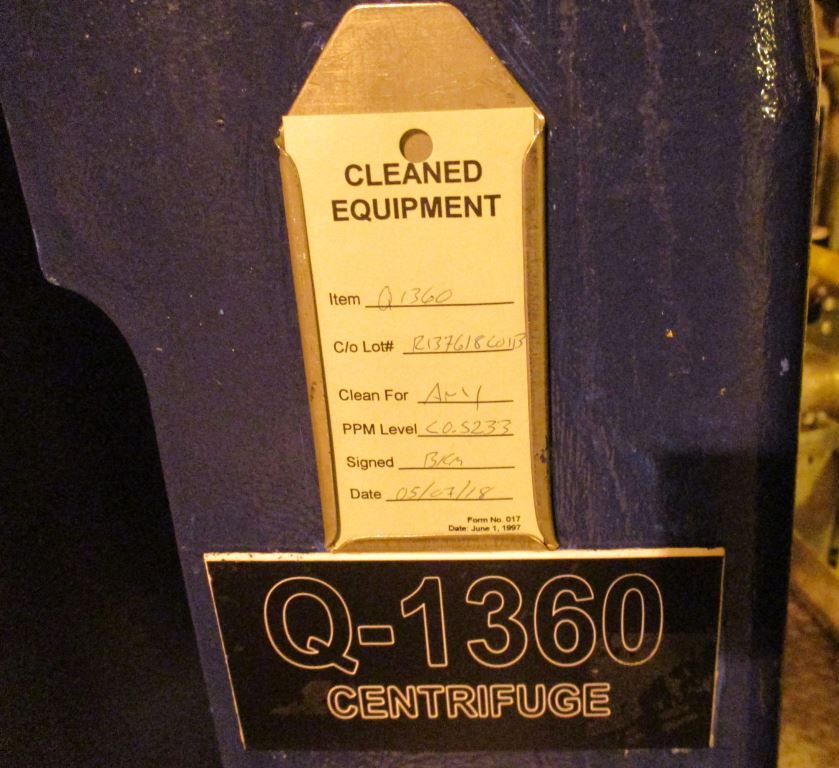

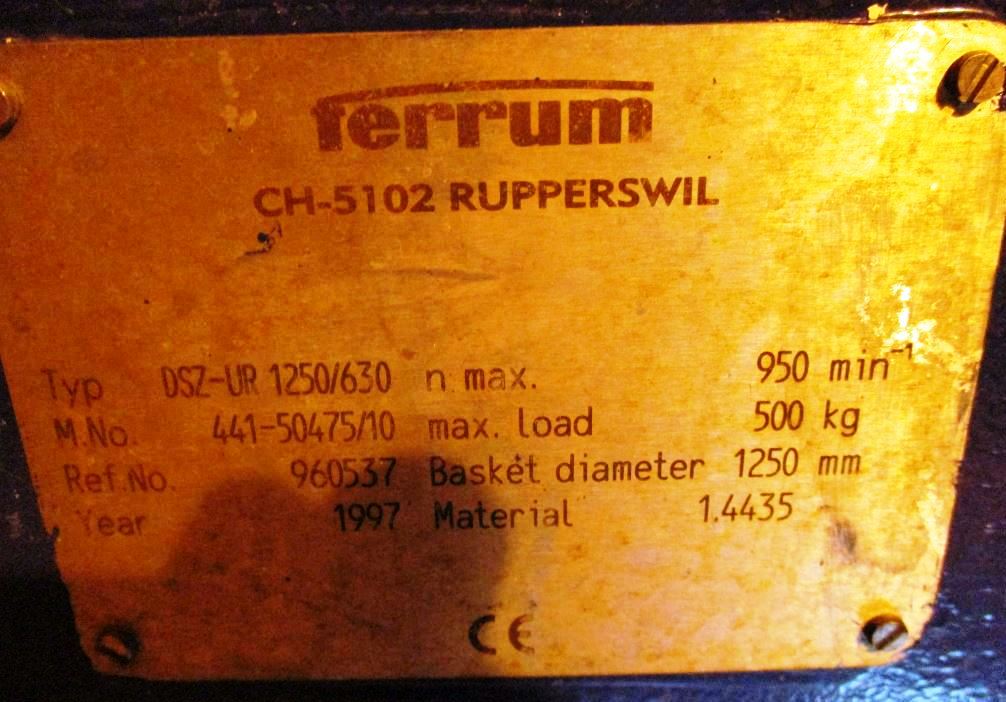

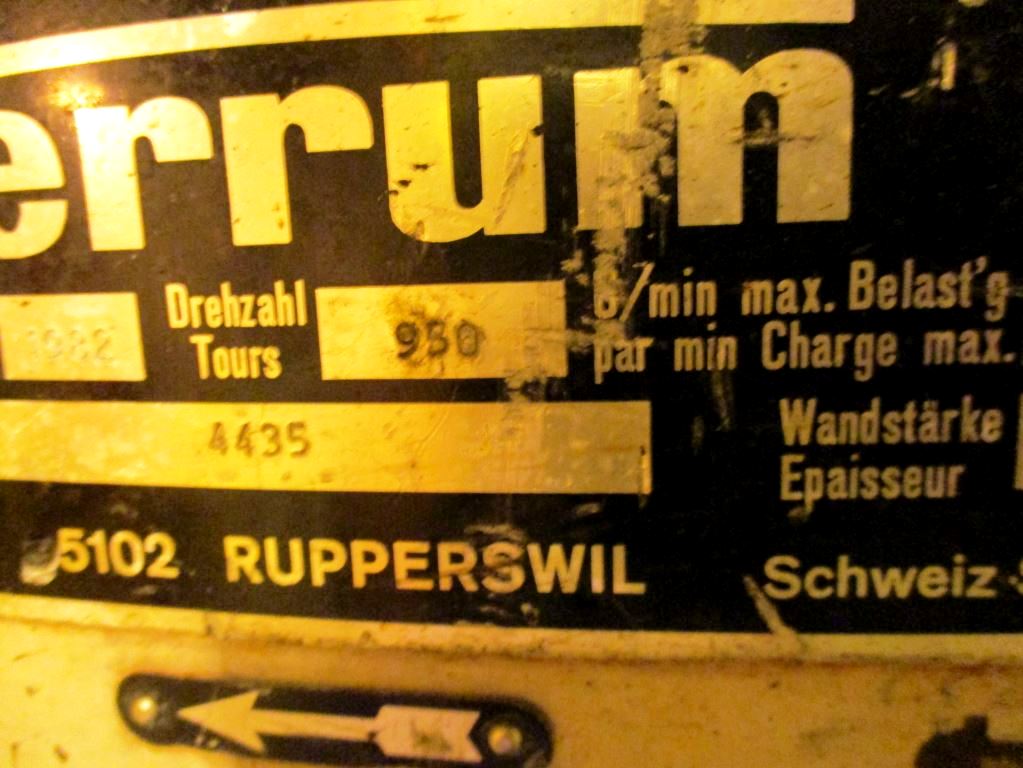

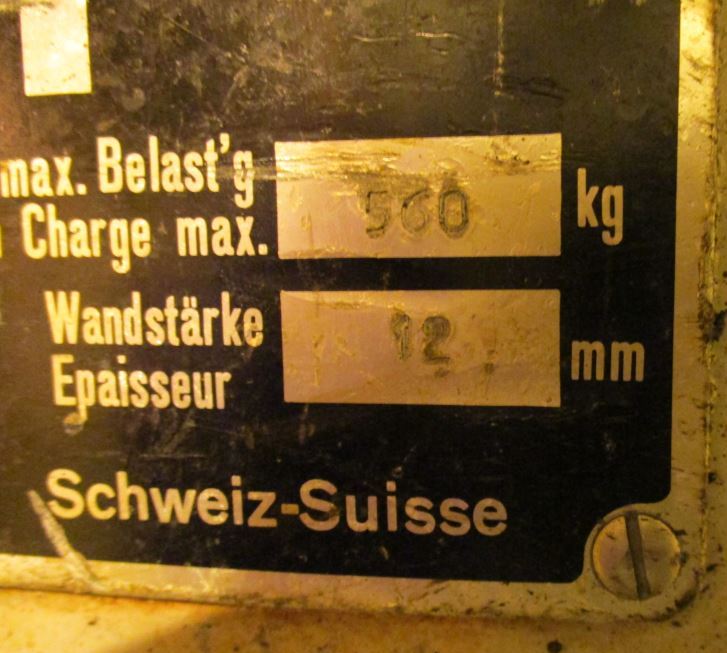

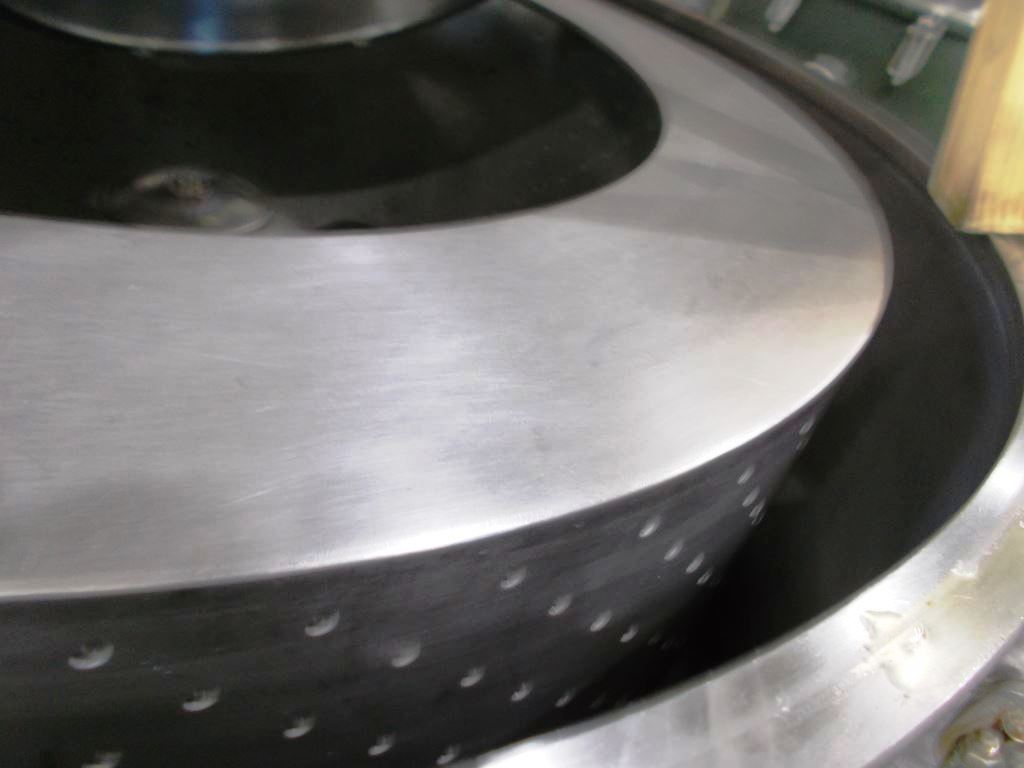

Max bowl speed 950 RPM, 630 x G, bottom dump, gas-tight, 26.5 sqft filtration area, 500 kg max load, 104 G volume, nitrogen purge, GMP/FDA approved sanitary design. 18.5 KW motor 460/3/60/1750 RPM, pneumatic heel cake removal feature, CIP spray balls, hydraulic power pack for lid lifting, feed pipe and sight glass. Prior use: Pharmaceutical. Excellent condition.

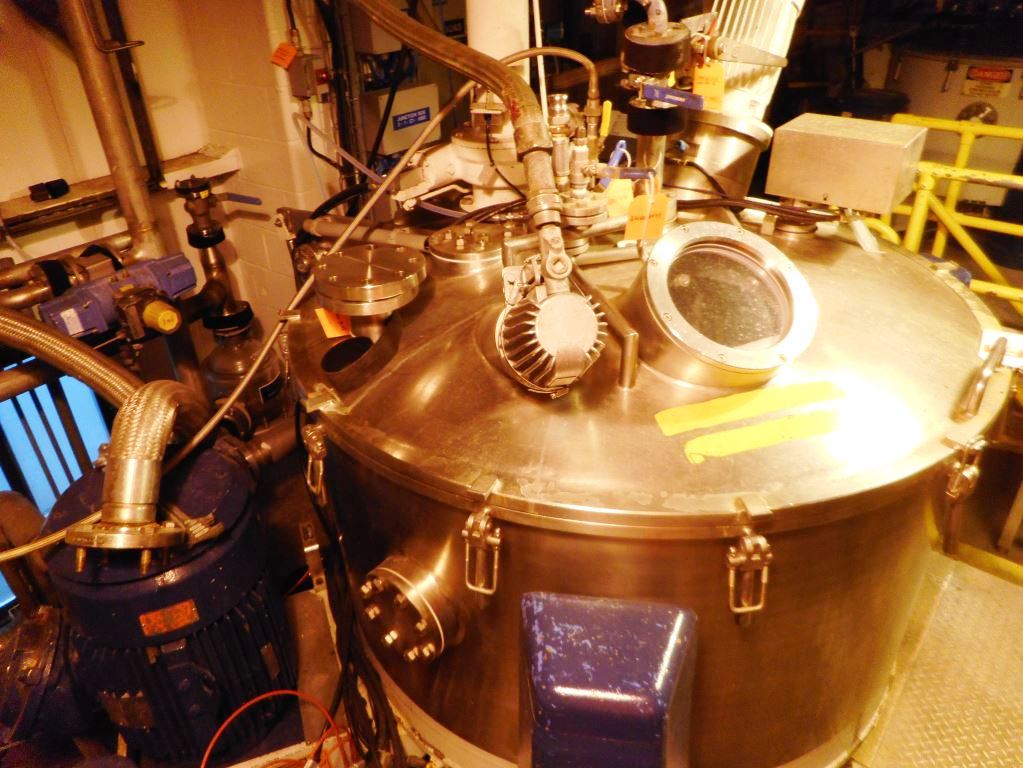

The (4) Ferrum DSZ-URF 1250/630 perforate basket centrifuges, 316L SS, are engineered for high-performance applications in the pharmaceutical industry, where precision and reliability are paramount. With a maximum bowl speed of 950 RPM and a gravitational force of 630 x G, these centrifuges are designed to efficiently separate solids from liquids, ensuring optimal product yield and quality. The bottom dump feature allows for easy discharge of processed materials, while the gas-tight construction ensures that the integrity of the process is maintained, preventing contamination and ensuring compliance with stringent industry standards. The generous filtration area of 26.5 square feet provides ample surface for effective separation, making these centrifuges ideal for large-scale operations with a maximum load capacity of 500 kg and a volume of 104 G.

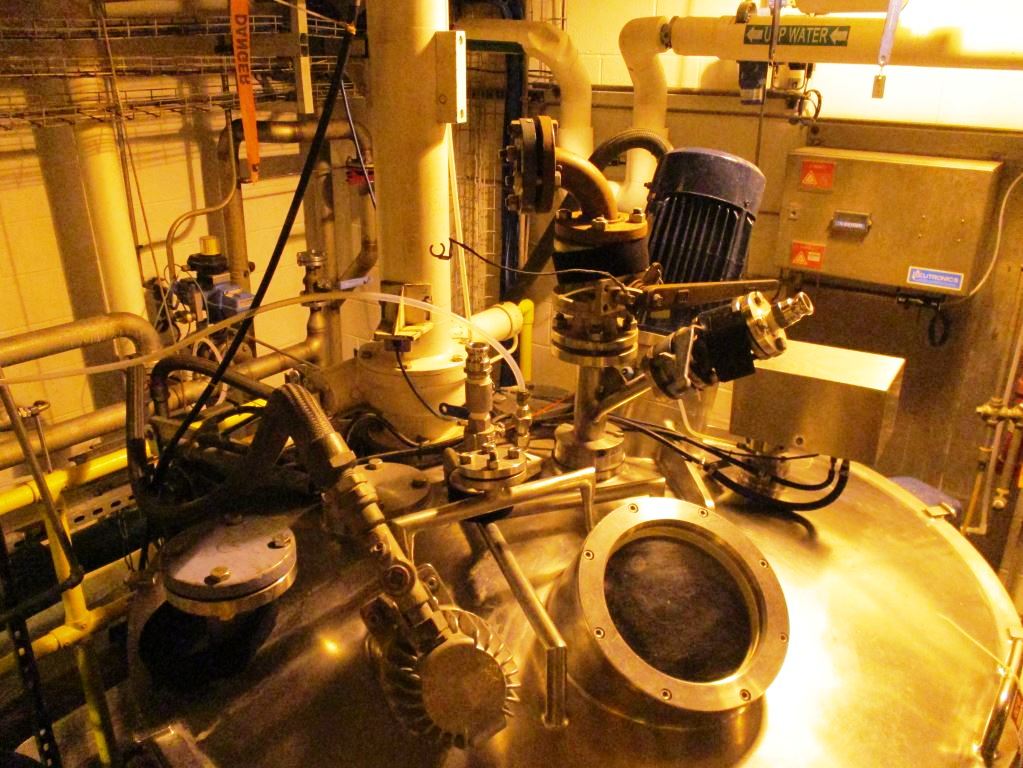

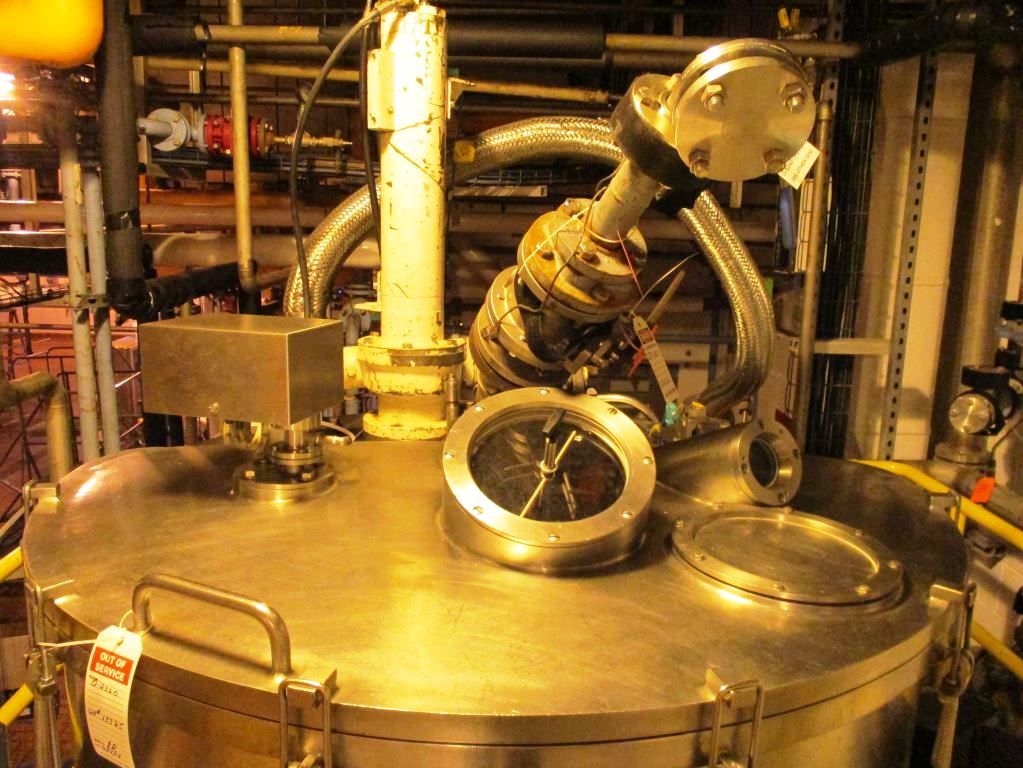

Designed with a focus on user convenience and operational efficiency, the (4) Ferrum DSZ-URF 1250/630 centrifuges are equipped with advanced features such as a nitrogen purge system, which enhances the safety and reliability of the process by minimizing the risk of oxidation. The GMP/FDA approved sanitary design ensures that these centrifuges meet the highest hygiene standards, making them suitable for pharmaceutical applications where product purity is critical. The 18.5 KW motor, operating at 460/3/60/1750 RPM, provides robust power for demanding tasks, while the pneumatic heel cake removal feature simplifies the cleaning process, reducing downtime and enhancing productivity. Additionally, the inclusion of CIP spray balls facilitates efficient cleaning in place, ensuring that the equipment remains in excellent condition for continuous operation.

Furthermore, the hydraulic power pack for lid lifting enhances the ease of access to the centrifuge interior, allowing for quick maintenance and inspection. The integrated feed pipe and sight glass provide operators with the ability to monitor the process visually, ensuring that adjustments can be made promptly to optimize performance. With prior use in the pharmaceutical sector and maintained in excellent condition, these centrifuges represent a valuable investment for any operation seeking to enhance its separation capabilities while adhering to the highest industry standards.

Key Features:

High-Speed Performance, Durable Construction, Easy Maintenance, Sanitary Design, Efficient Separation