Description:

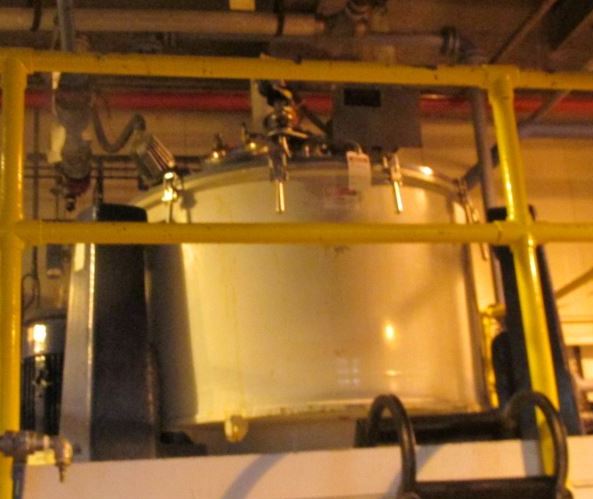

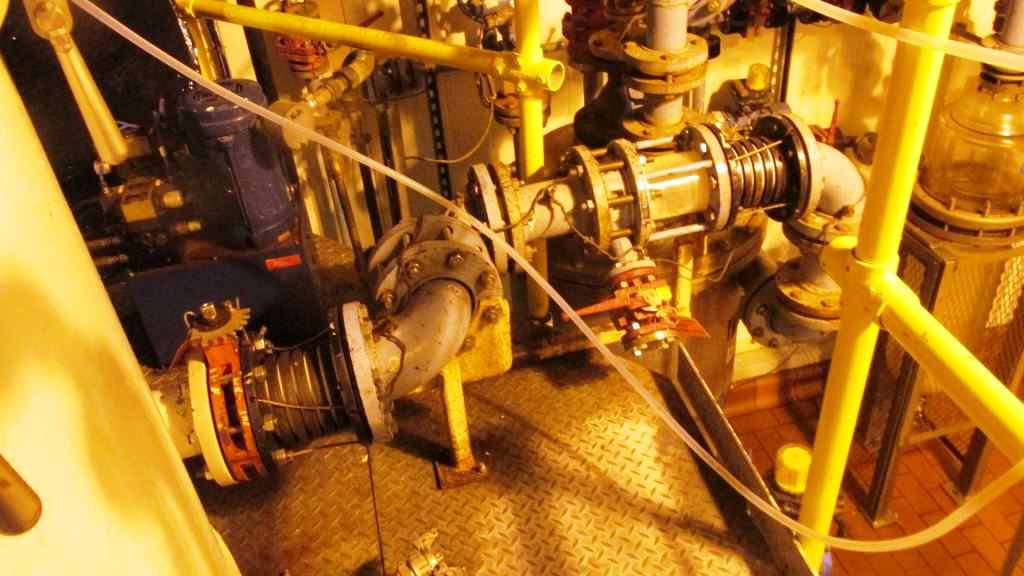

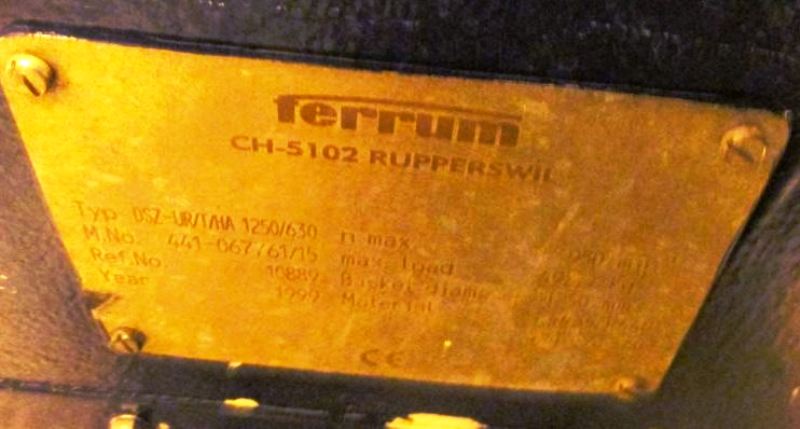

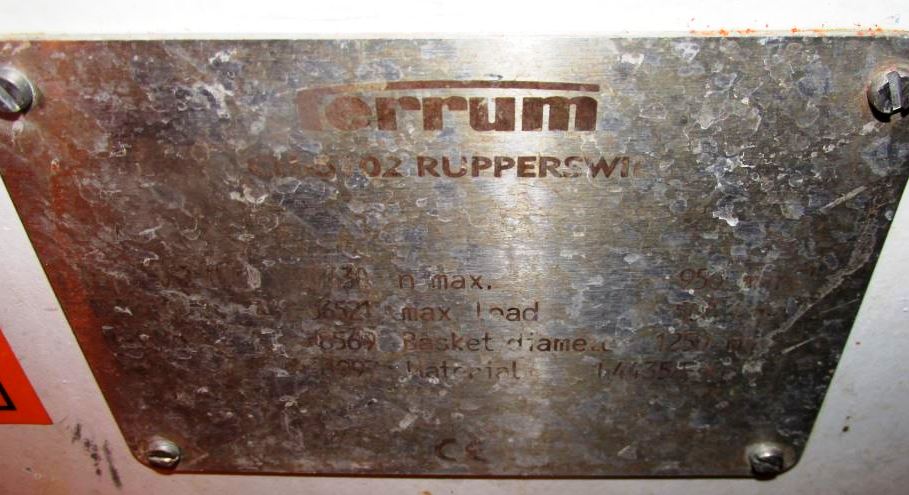

Max bowl speed 950 RPM, 630 x G, bottom dump, gas-tight, 26.5 sqft filtration area, 500 kg max load, 104 G volume, nitrogen purge, GMP/FDA approved sanitary design. 18.5 KW motor 460/3/60/1750 RPM, pneumatic heel cake removal feature, CIP spray balls, hydraulic power pack for lid lifting, feed pipe and sight glass. Prior use: Pharmaceutical. Excellent condition.

The Ferrum DSZ-UR/T/HA 1250/630 perforate basket centrifuge, Eldon-coated, is engineered for high-performance separation processes in the pharmaceutical industry. With a maximum bowl speed of 950 RPM and a centrifugal force of 630 x G, this centrifuge is capable of efficiently processing a variety of materials while ensuring optimal separation and clarity. The unit features a bottom dump design that allows for easy discharge of the separated solids, while its gas-tight construction ensures that the integrity of the process is maintained, preventing contamination and preserving the quality of the product. With a filtration area of 26.5 square feet, this centrifuge can handle a maximum load of 500 kg and a volume of 104 gallons, making it suitable for both small and large-scale operations.

Designed with a focus on compliance and safety, the Ferrum DSZ-UR/T/HA 1250/630 is GMP/FDA approved, ensuring that it meets the stringent standards required in pharmaceutical manufacturing. The 18.5 KW motor, operating at 460V/3/60/1750 RPM, provides robust power for reliable operation, while the pneumatic heel cake removal feature enhances efficiency by simplifying the cleaning process. The inclusion of CIP (Clean-In-Place) spray balls allows for thorough cleaning without the need for disassembly, further streamlining maintenance. Additionally, the hydraulic power pack for lid lifting facilitates easy access to the bowl for maintenance and inspection, and the integrated feed pipe and sight glass provide operators with real-time monitoring of the process. Overall, this centrifuge represents a blend of advanced technology, user-friendly design, and compliance with industry standards, making it an invaluable asset for any pharmaceutical facility.

Key Features:

High-Speed Performance, Durable Construction, Easy Maintenance, GMP/FDA Approved, Efficient Separation