Description:

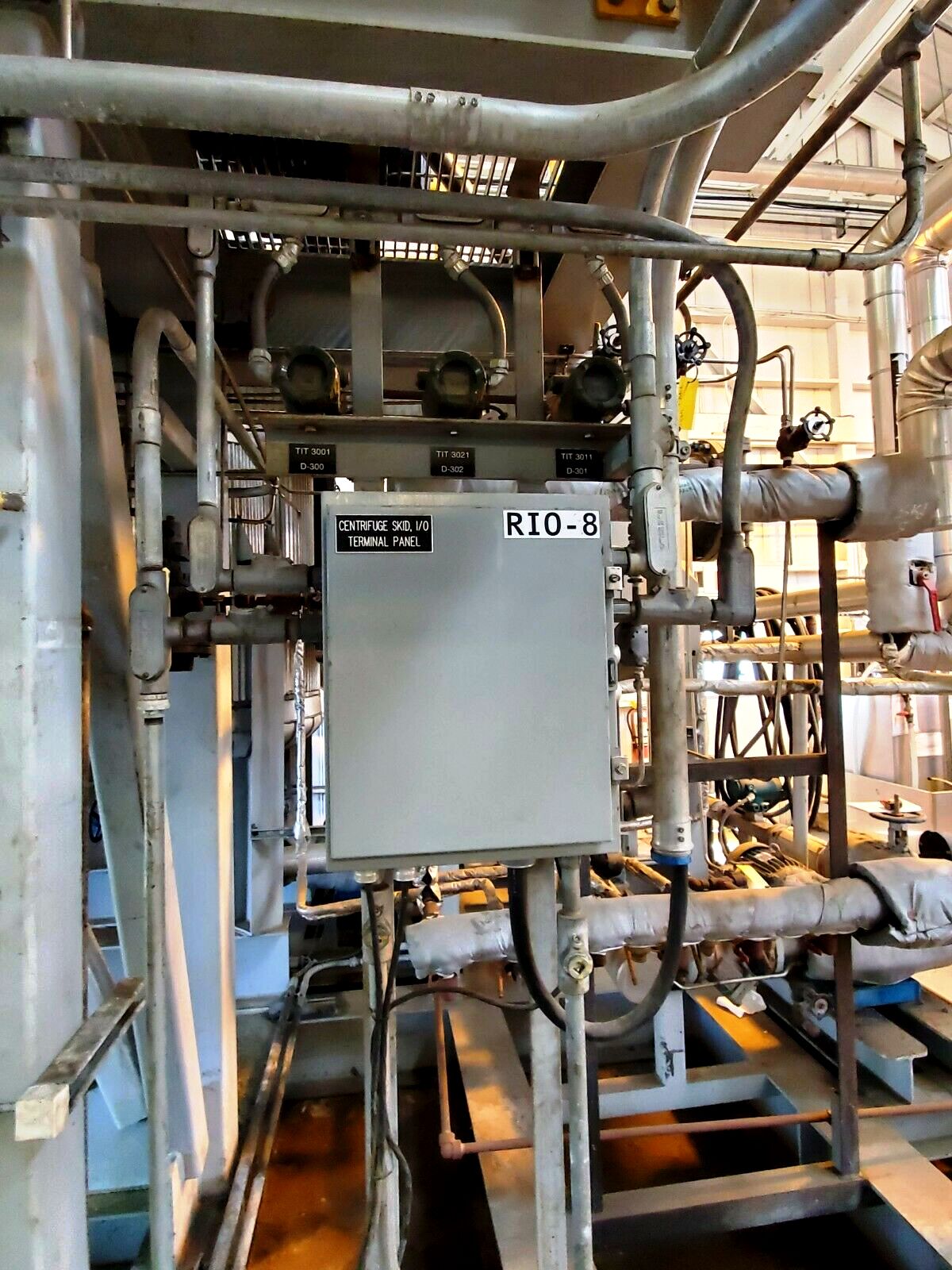

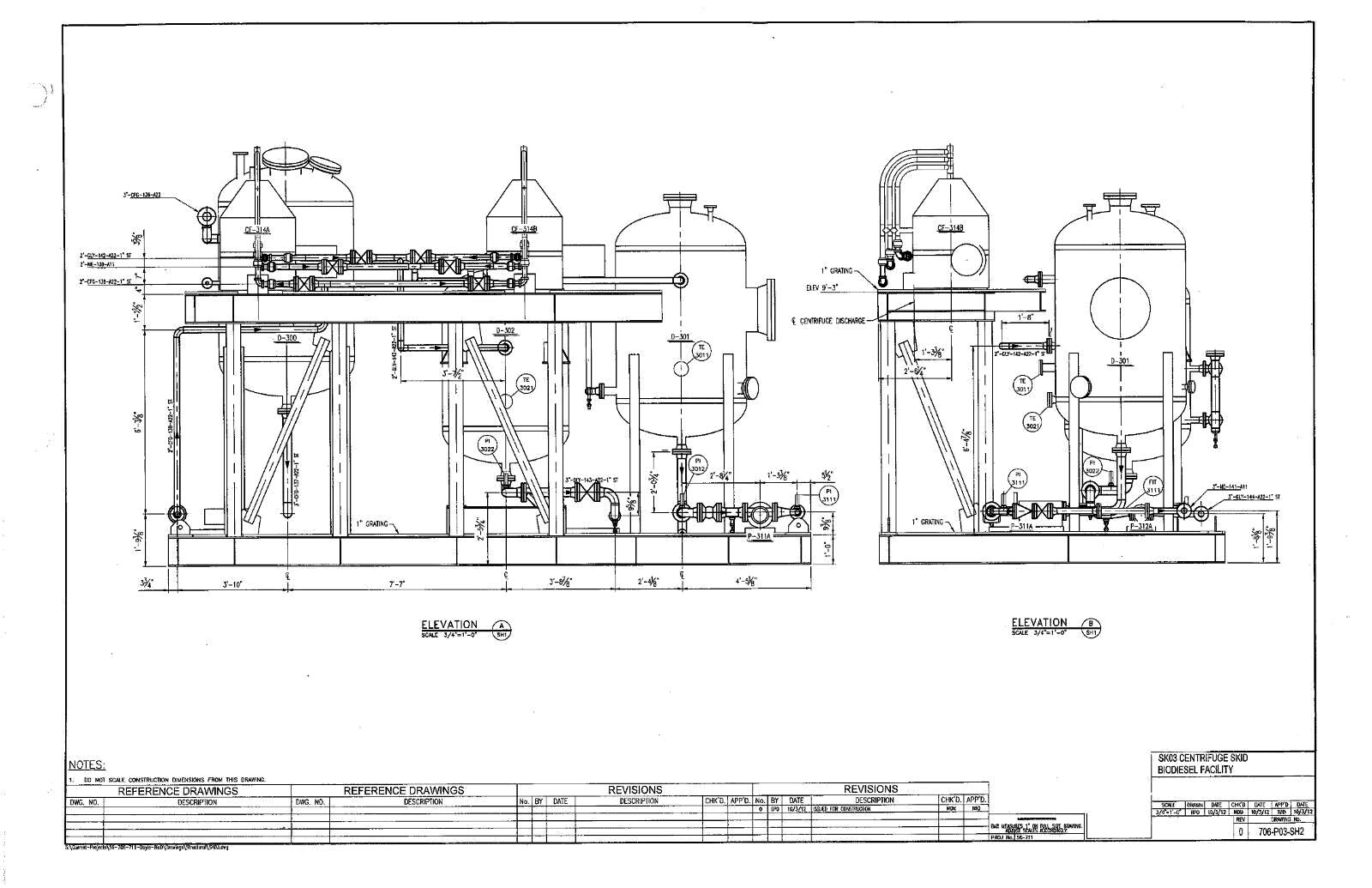

Max bowl speed 4000 RPM, rated @ 83 GPM, 4.5 gal sludge capacity, both liquid phases discharged under pressure, 20 HP XP motor 230/460/3/60/1760 RPM, feed pump, back pressure control valve, water harness, tools, manual and control panel. 650 G feed tank, 600 G light phase receiver and 400 G heavy phase receiver tank. 249 sqft shell and tube heat exchanger, 40 GPM Viking feed pump with 3 HP XP motor, 40 GPM light phase transfer and 5 GPM heavy phase transfer pump, control valves, instruments, safety devices, etc. Welded steel skid support structure to support centrifuges, heat exchangers, vessels, filters, pumps, piping, and instruments. All original drawings, engineering calculations, vessel drawings, ASME U-1A data reports, etc. Like new condition. The system was designed and constructed in 2014, but used only intermittently since. This equipment has been photographed, documented, tagged, disconnected, carefully removed, and is ready for immediate shipment.

The (2) Alfa-Laval MAPX 313 TGT-24-60 biodiesel skids, 316SS, are engineered for high-efficiency biodiesel production, featuring a robust design that ensures optimal performance in demanding industrial environments. With a maximum bowl speed of 4000 RPM, these skids are capable of processing up to 83 gallons per minute (GPM), making them an ideal choice for operations requiring significant throughput. The integrated 20 HP XP motor operates at 230/460 volts and 60 Hz, providing reliable power to drive the system. The equipment includes essential components such as a feed pump, back pressure control valve, and a comprehensive control panel, ensuring seamless operation and ease of monitoring. The system's sludge capacity of 4.5 gallons allows for effective waste management, minimizing downtime and enhancing productivity.

The biodiesel skids are equipped with a 650-gallon feed tank, a 600-gallon light phase receiver, and a 400-gallon heavy phase receiver tank, facilitating efficient separation and collection of biodiesel phases. The 249 square feet shell and tube heat exchanger is designed to optimize thermal efficiency, while the 40 GPM Viking feed pump, powered by a 3 HP XP motor, ensures consistent feed flow. Additionally, the system includes dedicated pumps for light and heavy phase transfer, rated at 40 GPM and 5 GPM respectively, along with necessary control valves and safety devices. Constructed with a welded steel skid support structure, the equipment is designed to support various components, including centrifuges, heat exchangers, vessels, filters, and piping, ensuring durability and stability during operation. With all original engineering documentation, including ASME U-1A data reports, this equipment is not only in like-new condition but also ready for immediate deployment, having been meticulously prepared for shipment.

Key Features:

High-Speed Performance, Efficient Phase Separation, Robust Construction, Comprehensive Safety Features, Ready for Immediate Shipment

Frequently Asked Questions

We're sorry, but this item has been sold.

Please consider the alternatives below.