Description:

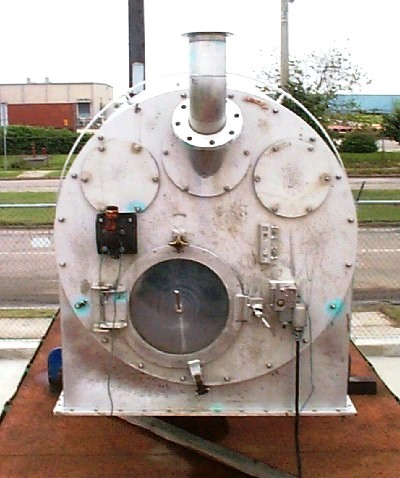

Max bowl speed 1050 RPM, 500 x G, 810/900mm basket diameter. 55 KW motor 400/3/50/1450 RPM, feed pipe, cyclo gear, 45 KW pusher motor, wash and rinse pipes, unitized on inertia base with vibration isolators. Prior use: Chemical. 1988 vintage. Excellent condition.

The Krauss-Maffei SZ 92 2-stage pusher centrifuge, 316SS, is engineered for high-efficiency separation processes, particularly suited for the chemical industry. With a maximum bowl speed of 1050 RPM and a centrifugal force of 500 x G, this centrifuge is capable of handling a wide variety of materials with precision and reliability. The 810/900mm basket diameter allows for substantial processing capacity, making it an ideal choice for operations requiring high throughput. The robust 55 KW motor operates at 400/3/50/1450 RPM, ensuring consistent performance under demanding conditions. Additionally, the inclusion of a 45 KW pusher motor enhances the unit's capability to effectively transport and separate materials, optimizing the overall efficiency of the separation process.

Constructed from high-grade 316 stainless steel, the Krauss-Maffei SZ 92 is designed to withstand corrosive environments while maintaining structural integrity. The unit's design features a feed pipe and cyclo gear, along with wash and rinse pipes, which facilitate easy cleaning and maintenance, ensuring that the centrifuge remains in excellent operational condition. The unitized construction on an inertia base with vibration isolators minimizes operational noise and enhances stability during high-speed operations. Despite being a vintage model from 1988, this centrifuge has been maintained in excellent condition, making it a reliable choice for businesses looking to invest in durable and effective separation technology.

Key Features:

High-Speed Performance, Durable Construction, Easy Maintenance, Efficient Separation, Vibration Isolation