Description:

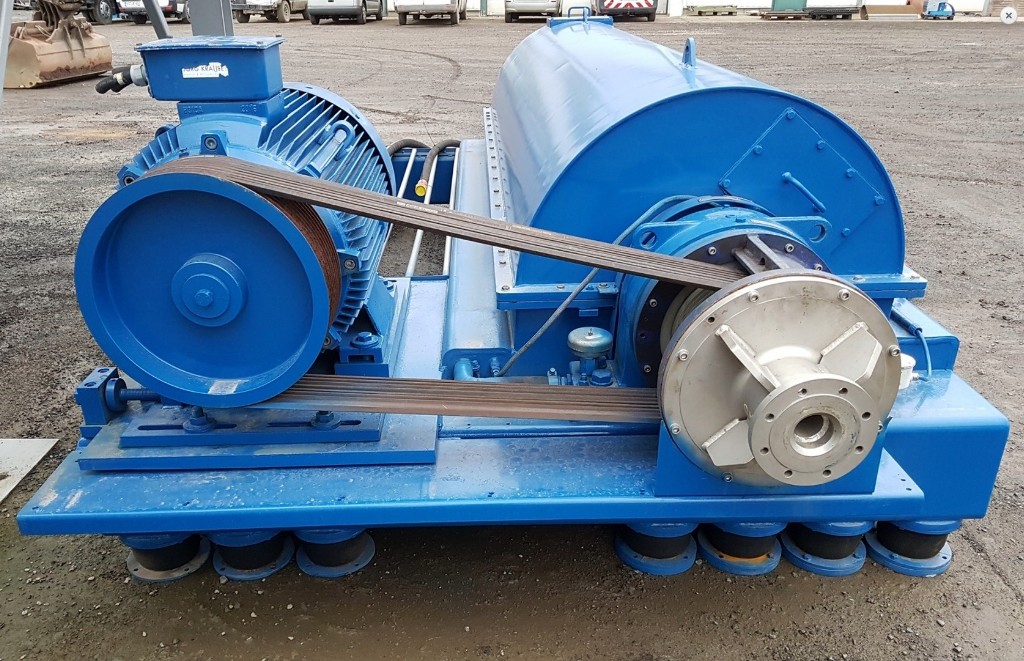

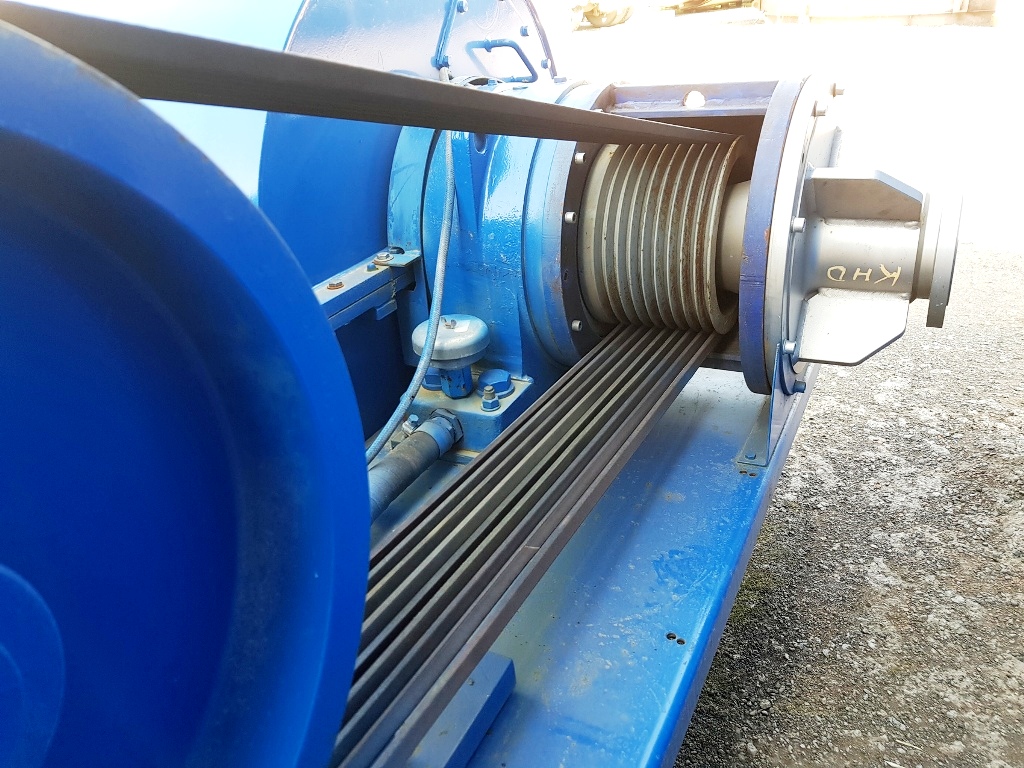

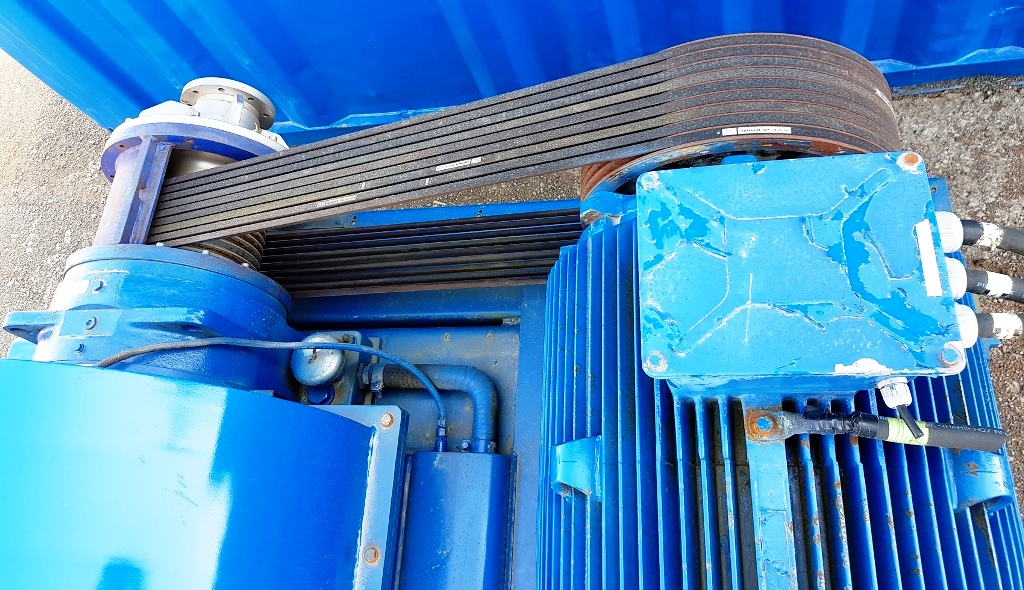

Max bowl speed 2500 RPM, 2620 x G, cyl/8 degree contour bowl, rated @ 300 GPM. End discharge cake ports with wear liners, ceramic tiled feed zone, adjustable plate dams, 12" single lead STC-tiled co-current conveyor, 132 KW motor 380/3/50/1485 RPM, planetary gearbox, lube system, feed tube and vibration isolators/switch. Prior use: Sewage dewatering. 1995 vintage. Reconditioned and ready to run. Located in Europe.

The Humboldt SC 4-02 (30 x 120) decanter centrifuge, CS. is engineered for high-performance separation processes, particularly in the demanding field of sewage dewatering. With a maximum bowl speed of 2500 RPM and a centrifugal force of 2620 x G, this centrifuge is designed to efficiently separate solids from liquids, ensuring optimal dewatering results. The cylindrical bowl features an 8-degree contour, which enhances the sedimentation process, allowing for a rated throughput of 300 gallons per minute (GPM). Its end discharge cake ports are equipped with wear liners, which provide added durability and longevity to the equipment, making it suitable for continuous operation in industrial environments. The ceramic tiled feed zone further enhances the wear resistance, ensuring that the centrifuge maintains its performance over time, even under heavy usage conditions.

This reconditioned unit, dating back to 1995, has been meticulously restored and is ready to run, making it a cost-effective solution for facilities looking to upgrade their dewatering capabilities without the expense of purchasing new equipment. The Humboldt SC 4-02 is powered by a robust 132 KW motor, operating at 380V, 3-phase, 50 Hz, and 1485 RPM, ensuring reliable and efficient operation. The integrated planetary gearbox and lubrication system contribute to the overall efficiency and reliability of the centrifuge, while the adjustable plate dams allow for fine-tuning of the separation process to meet specific operational requirements. Additionally, the inclusion of vibration isolators and switches enhances operational stability, reducing wear and tear on the machine and improving overall performance.

Key Features:

High-Speed Performance, Durable Construction, Efficient Dewatering, Robust Motor and Gearbox, Easy Installation and Maintenance