Description:

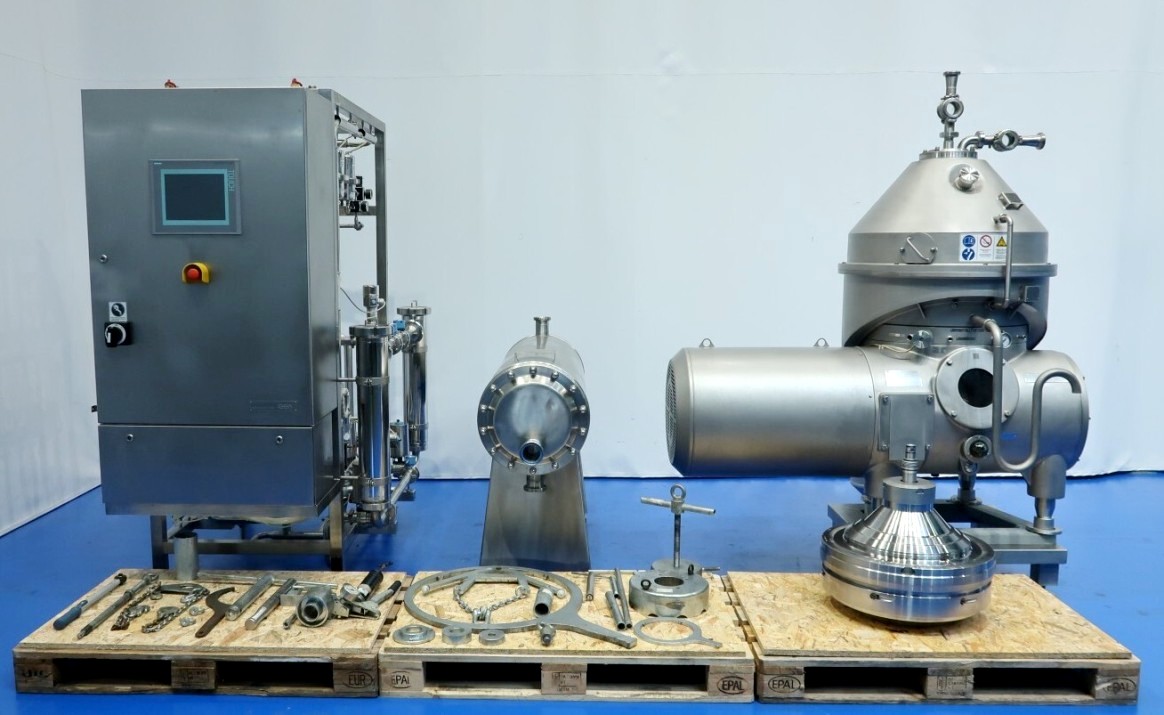

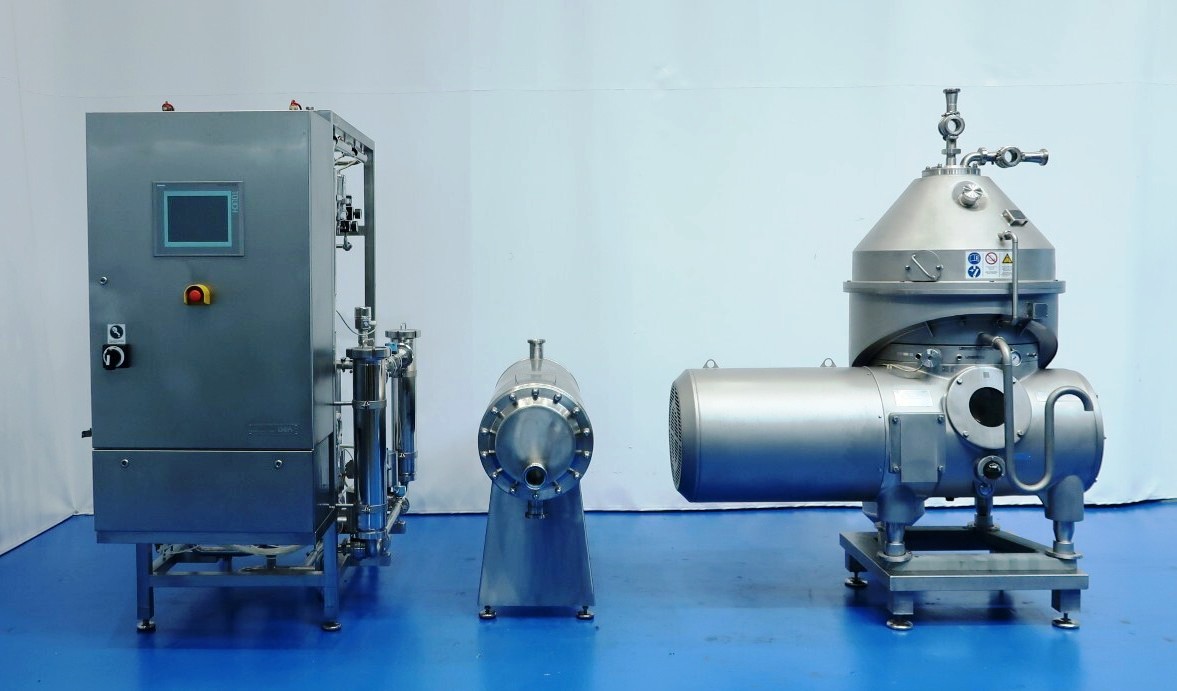

Max bowl speed 6000 RPM, rated @ 4000-5400 LPH input, 900-1100 KPH output @ 18%. 22 KW motor 400/690/3/50/1480 RPM, solids cyclone, flow meter, filters, valves, sensors, base frame, vibration isolators, spare parts kit, tools and full documentation. CIP system, Westfalia C1000 cooler with 18.5 KW motor and sterile air filter, motor starter, PLC control panel with VFDs and touch screen HMI. 2010 vintage. Excellent condition. Located in Europe.

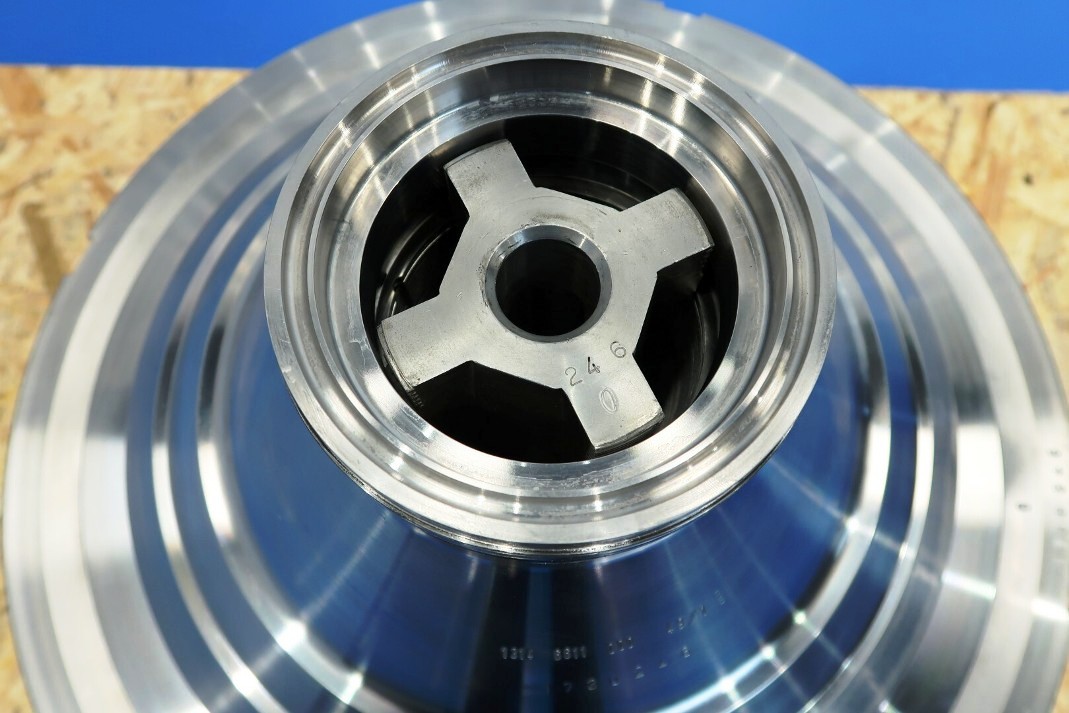

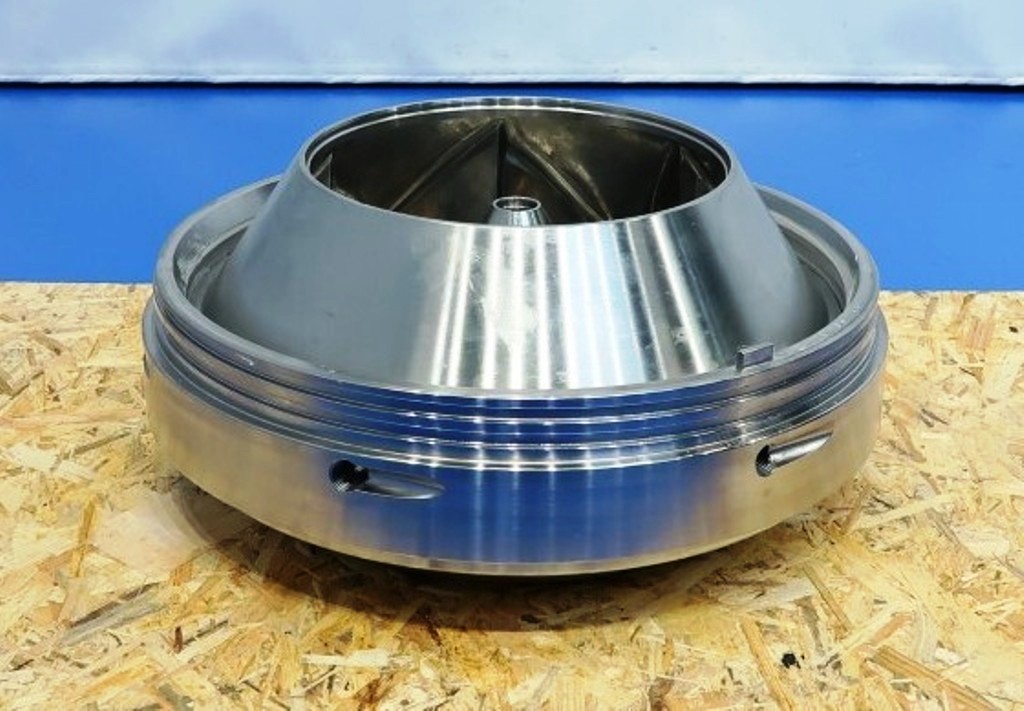

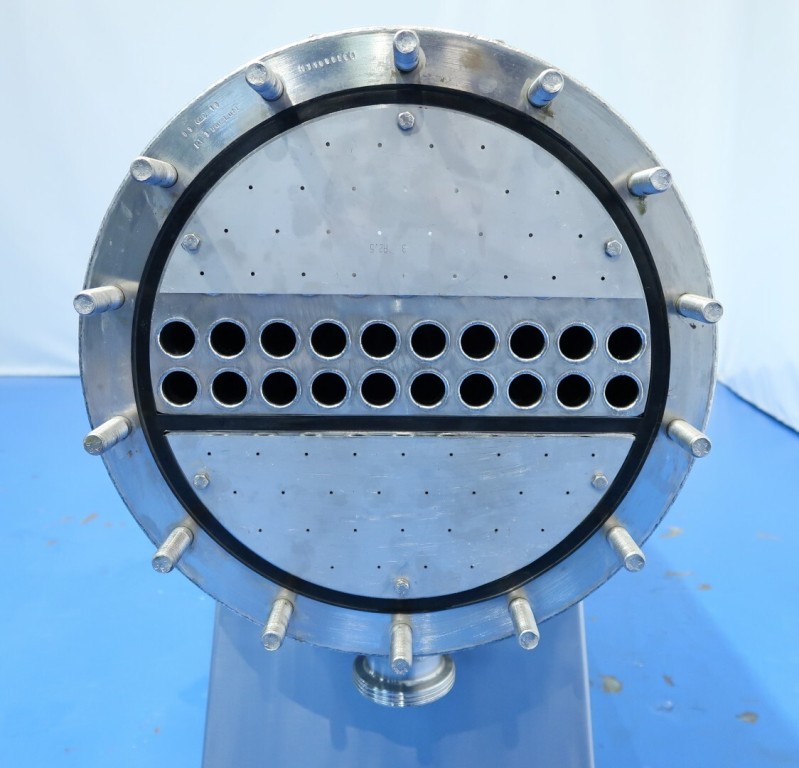

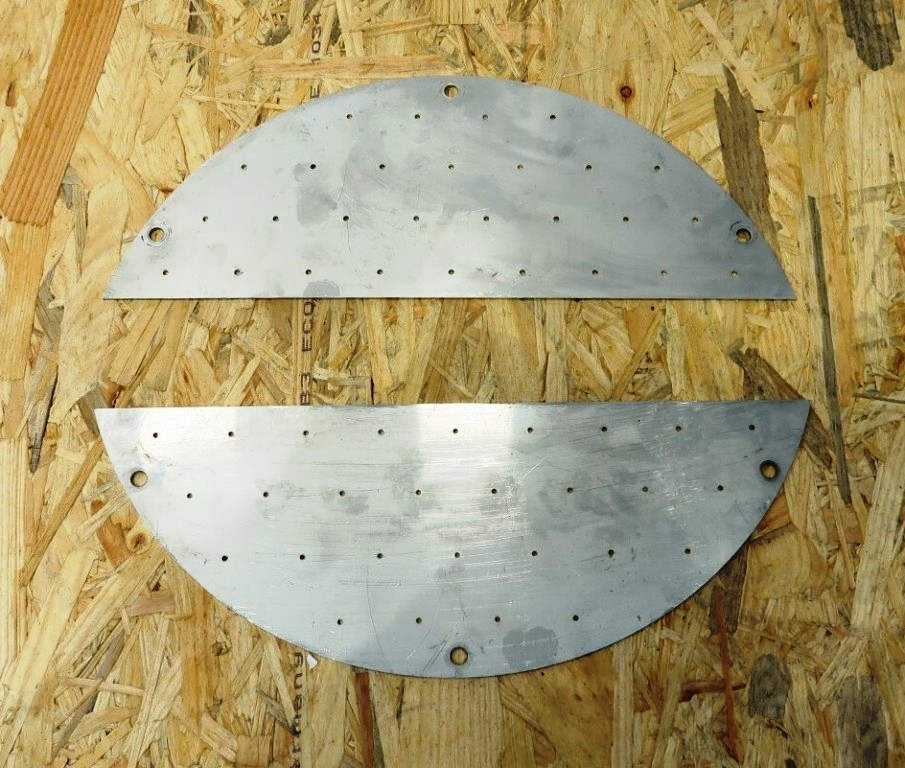

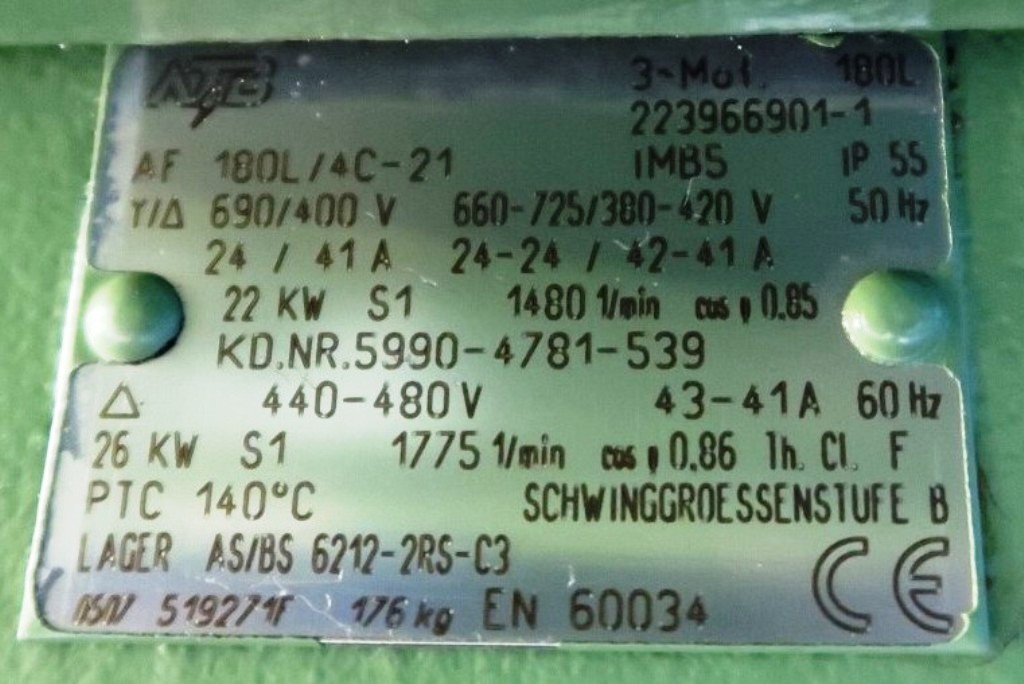

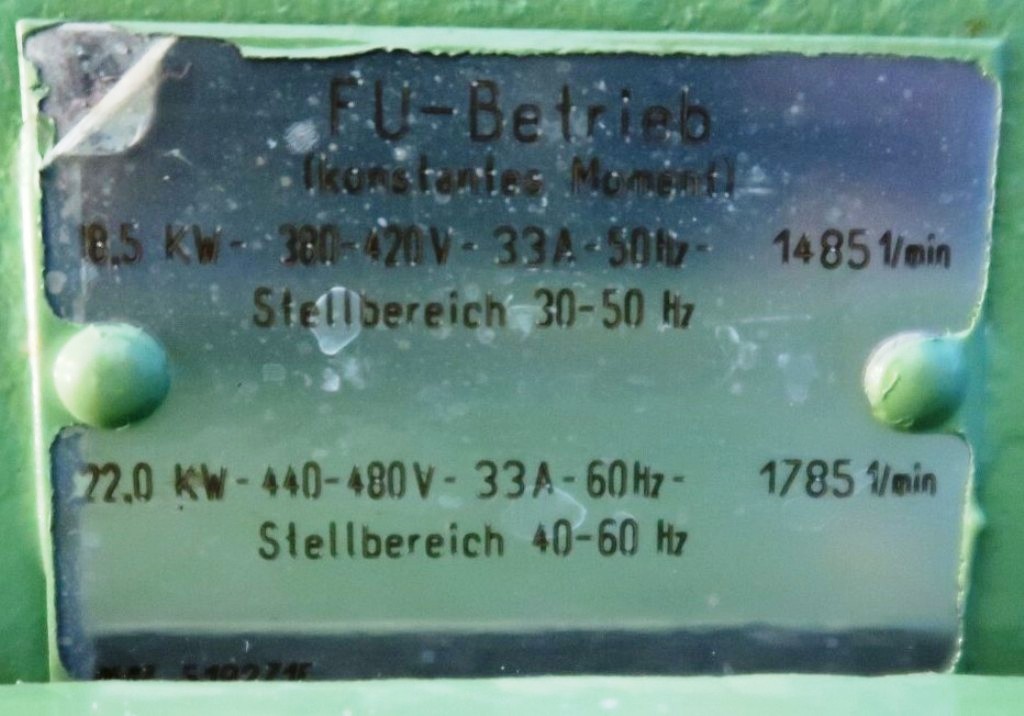

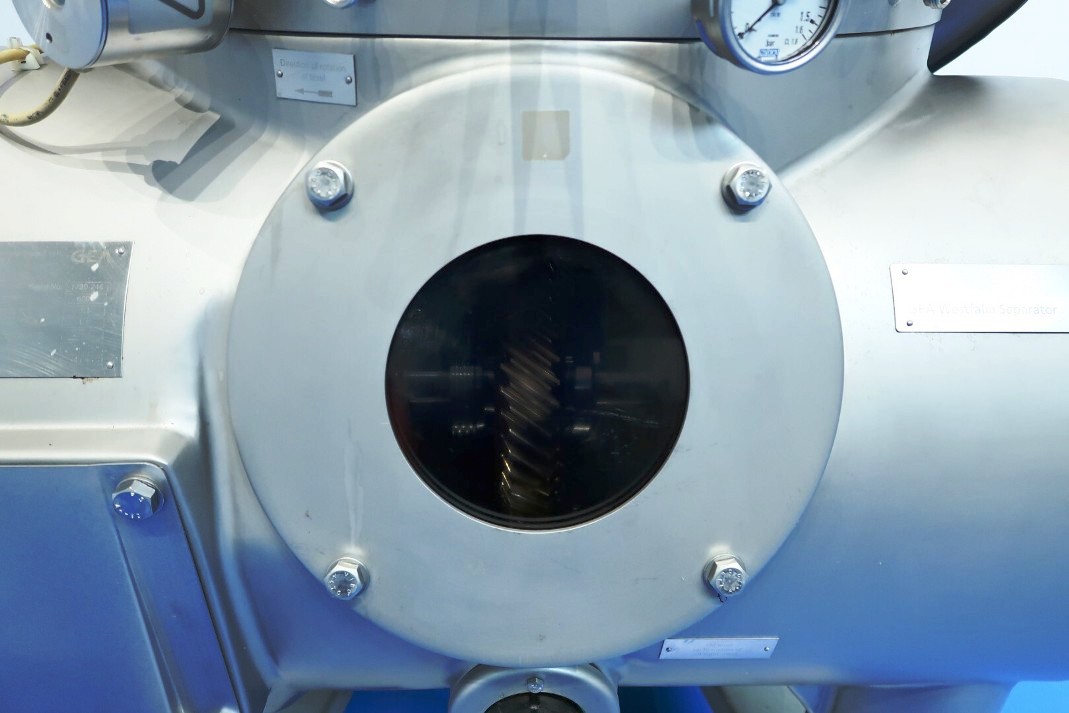

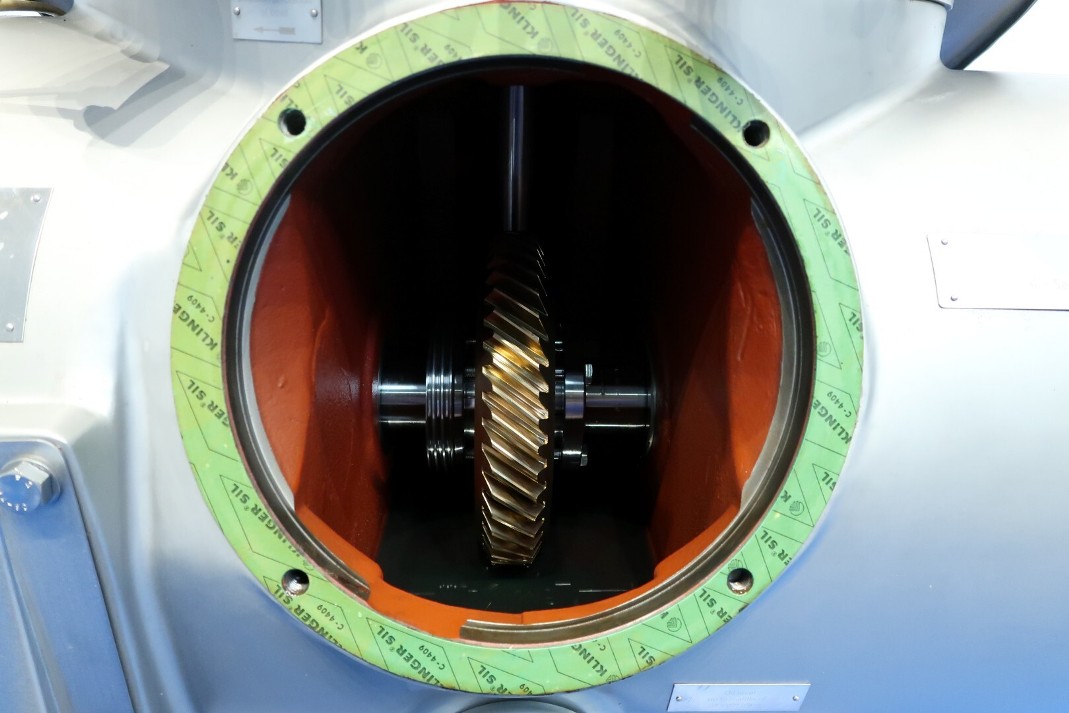

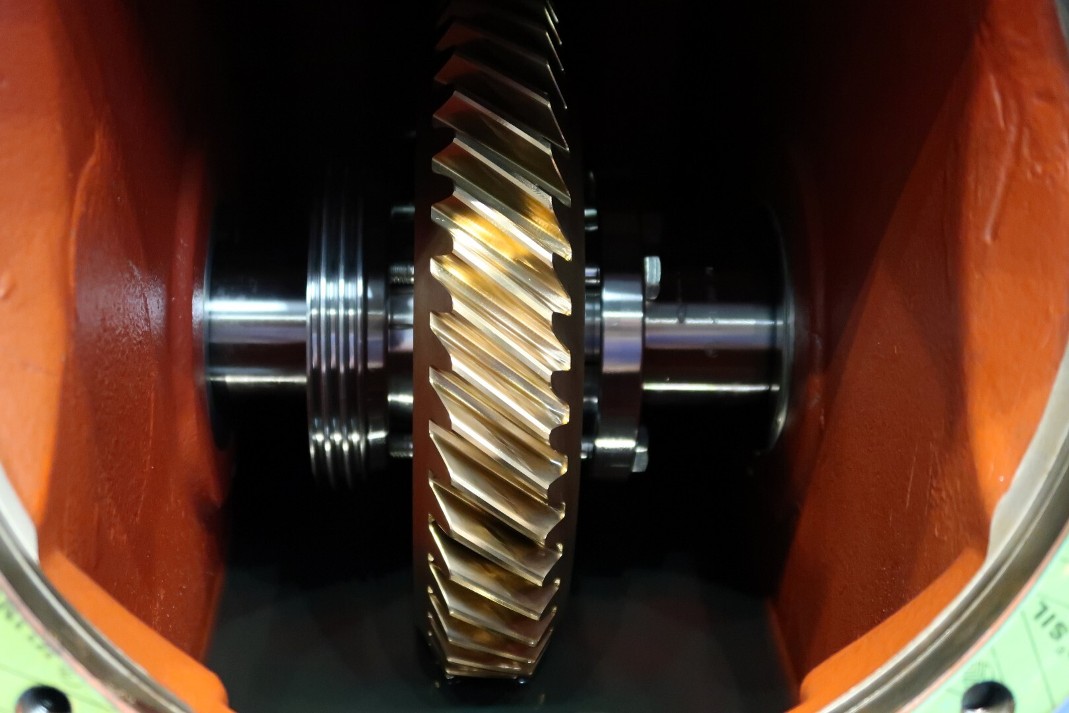

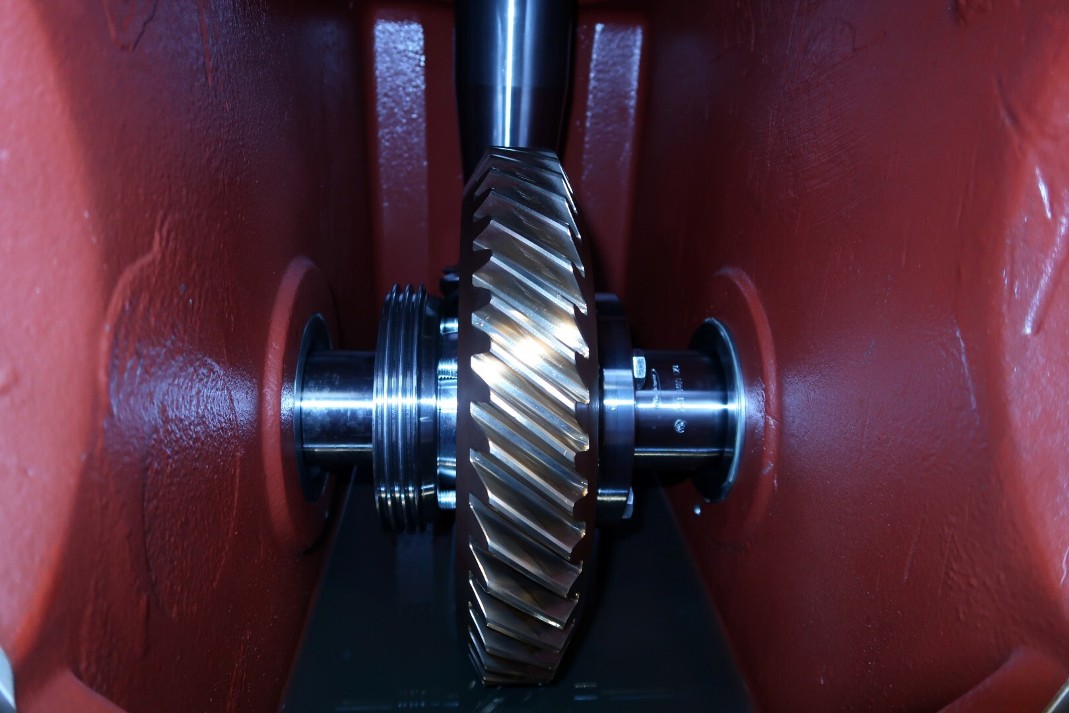

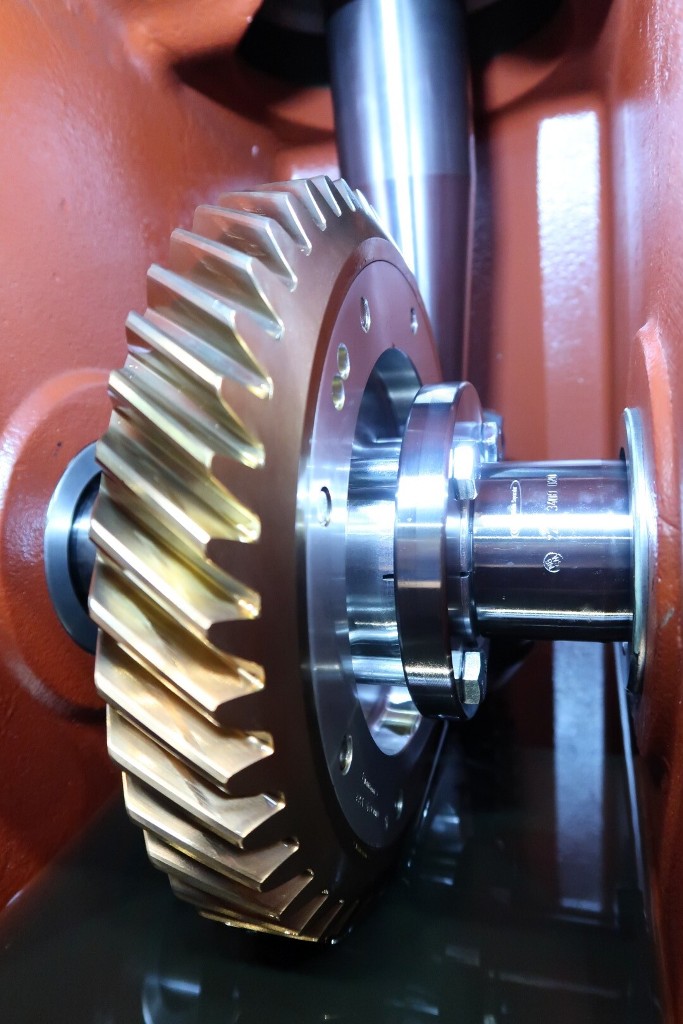

The Westfalia KDB 16-02-076 quark/yogurt nozzle separator, 316SS, is engineered for high efficiency and reliability in the dairy processing industry. With a maximum bowl speed of 6000 RPM, this separator is capable of handling a substantial input flow rate of 4000-5400 LPH, translating to an impressive output of 900-1100 KPH at a solids concentration of 18%. This level of performance is essential for operations that require consistent quality and high throughput, making it an ideal choice for producers of quark and yogurt. The robust 22 KW motor, compatible with 400/690V three-phase power supply at 50 Hz, ensures that the separator operates smoothly and efficiently, even under demanding conditions. The inclusion of a solids cyclone, flow meter, filters, valves, and sensors enhances the operational capabilities of the unit, allowing for precise control and monitoring of the separation process.

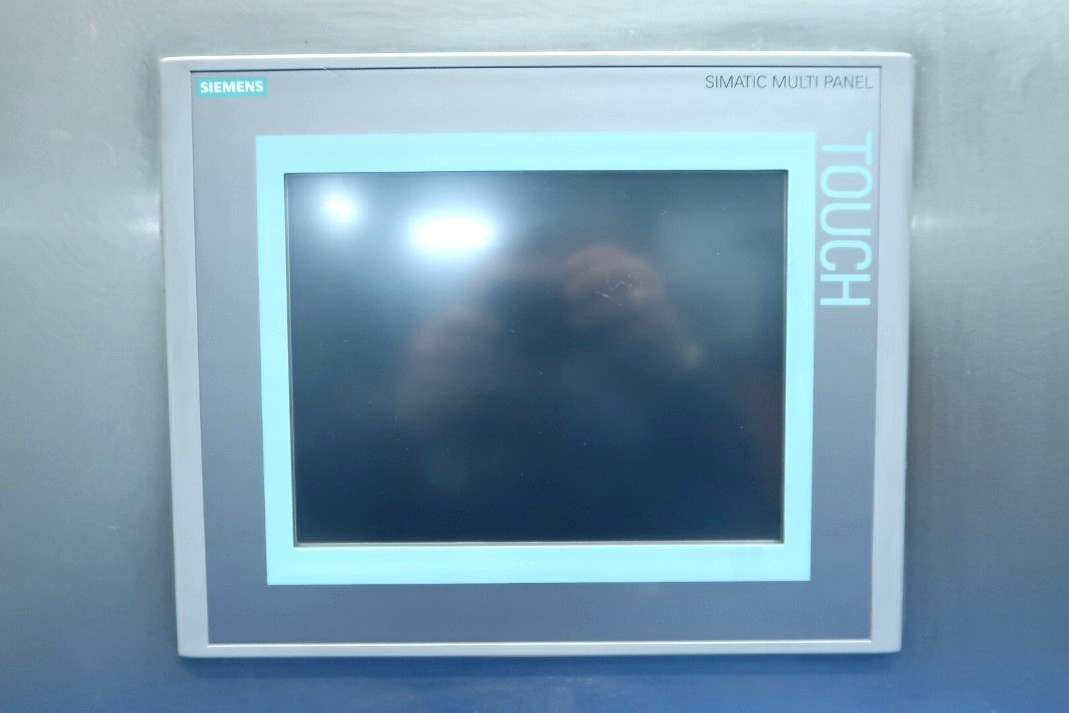

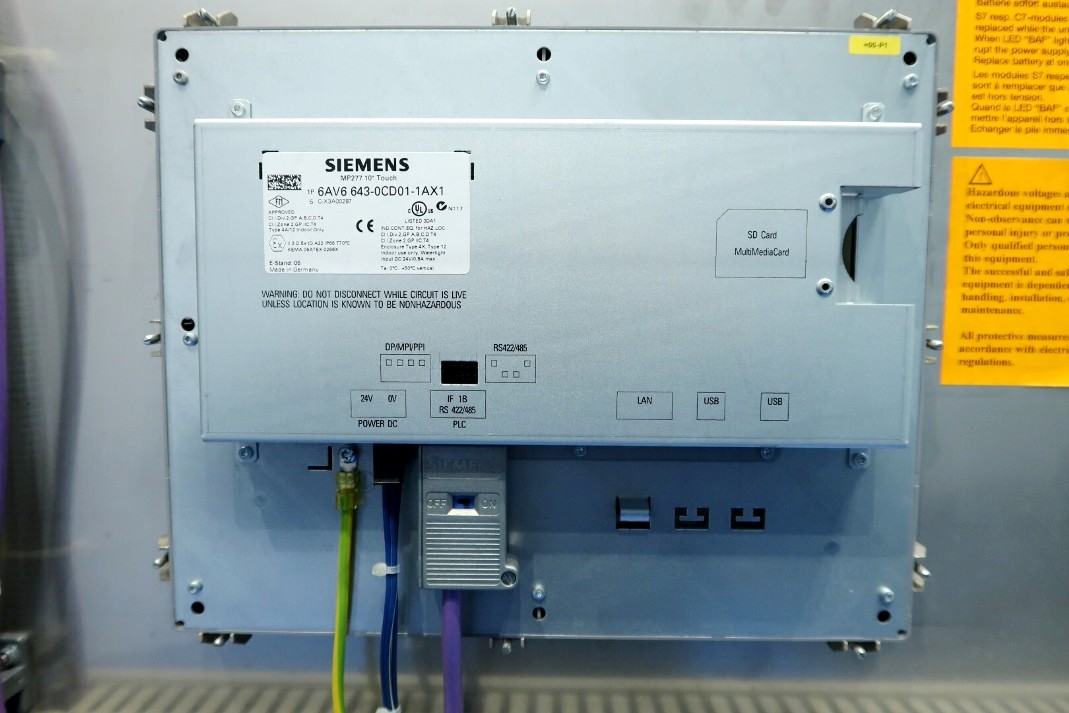

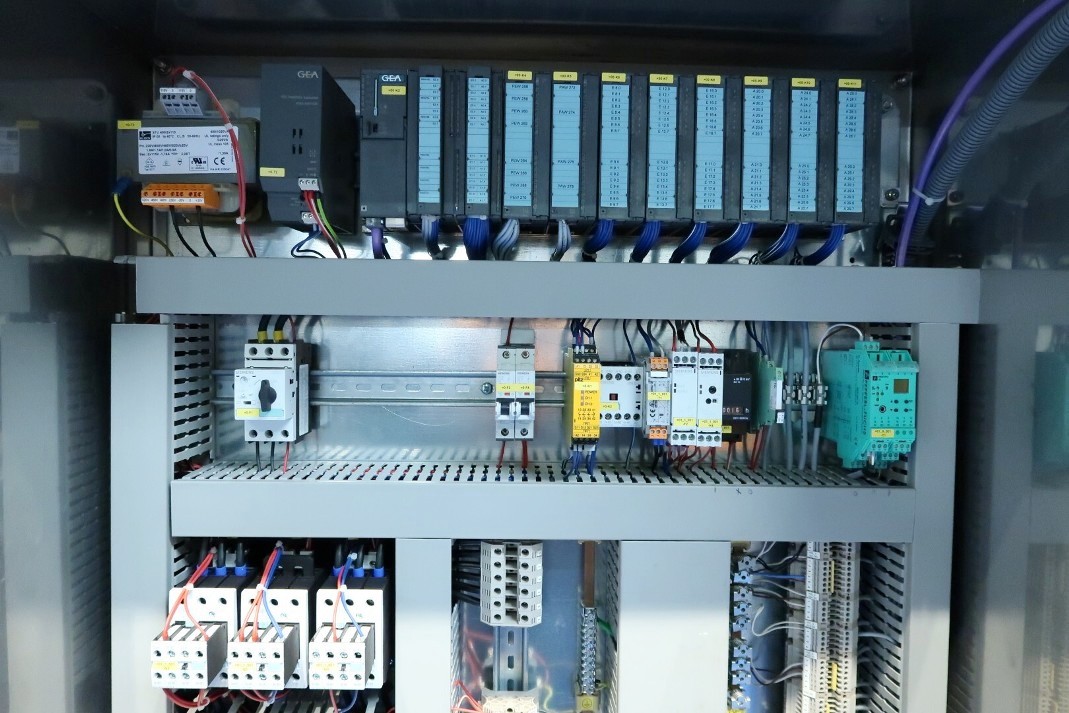

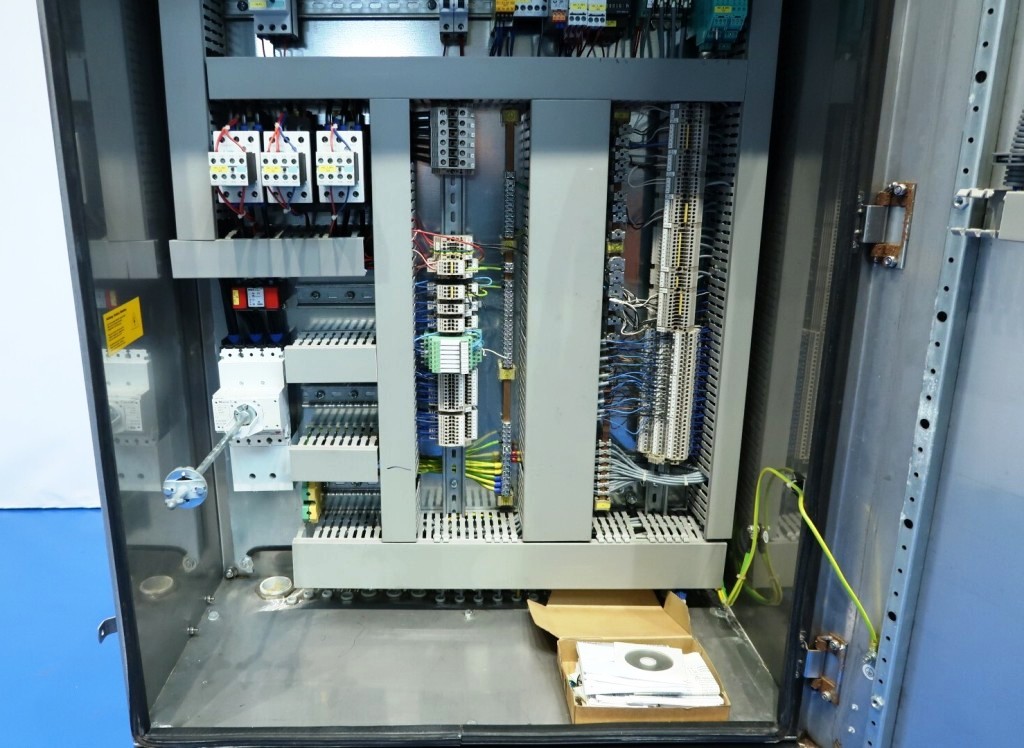

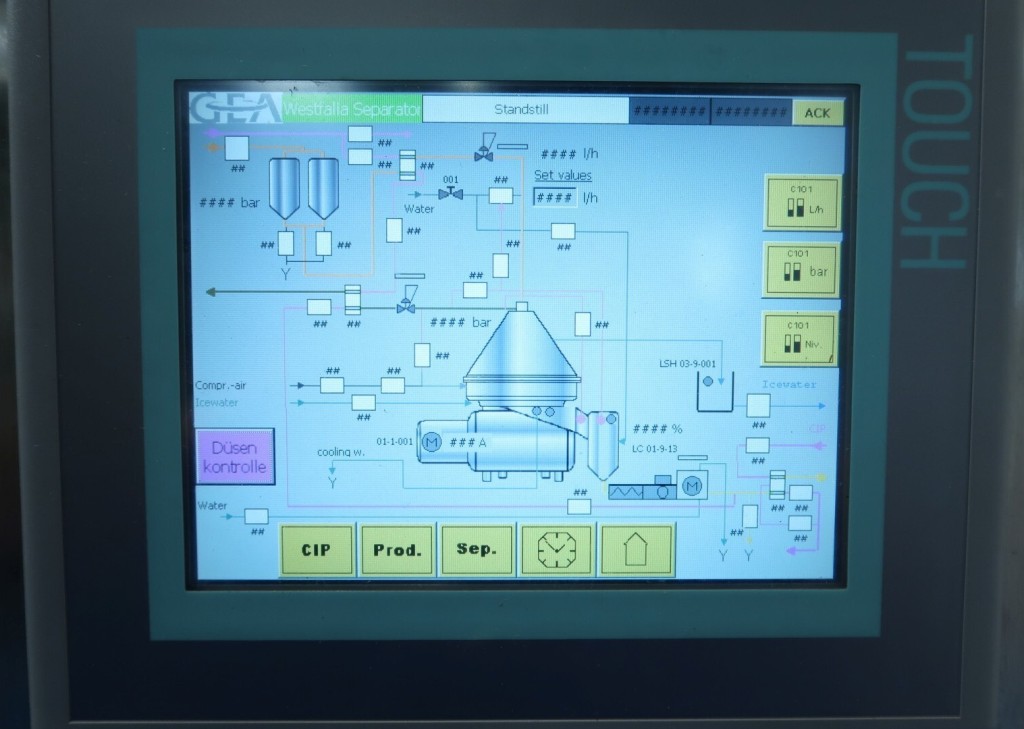

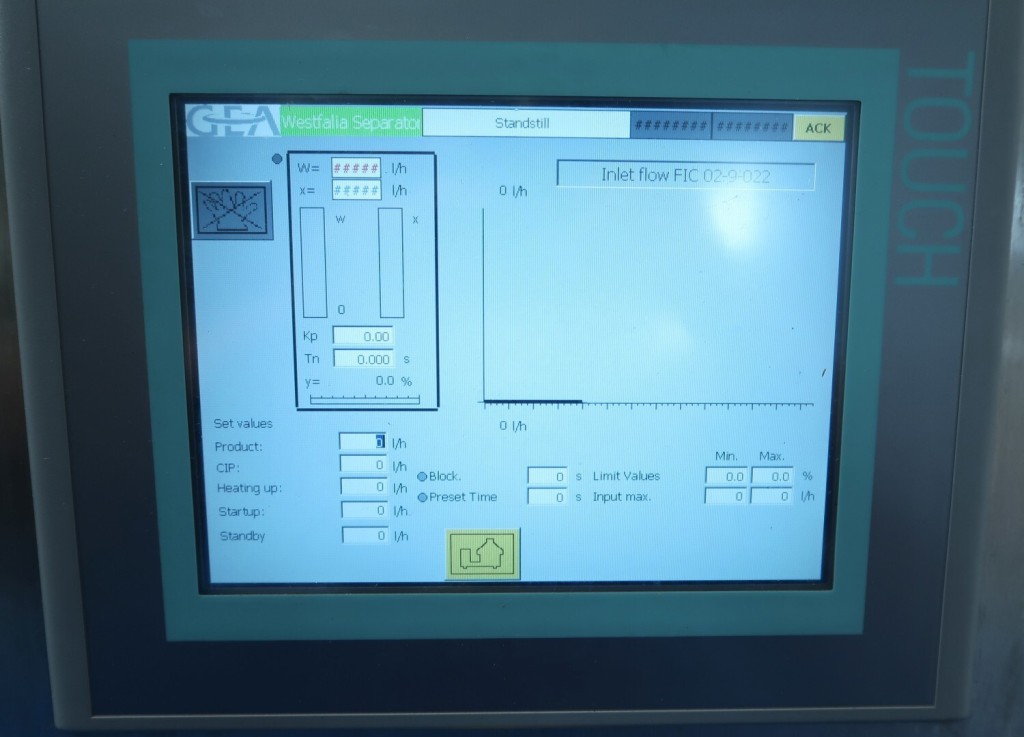

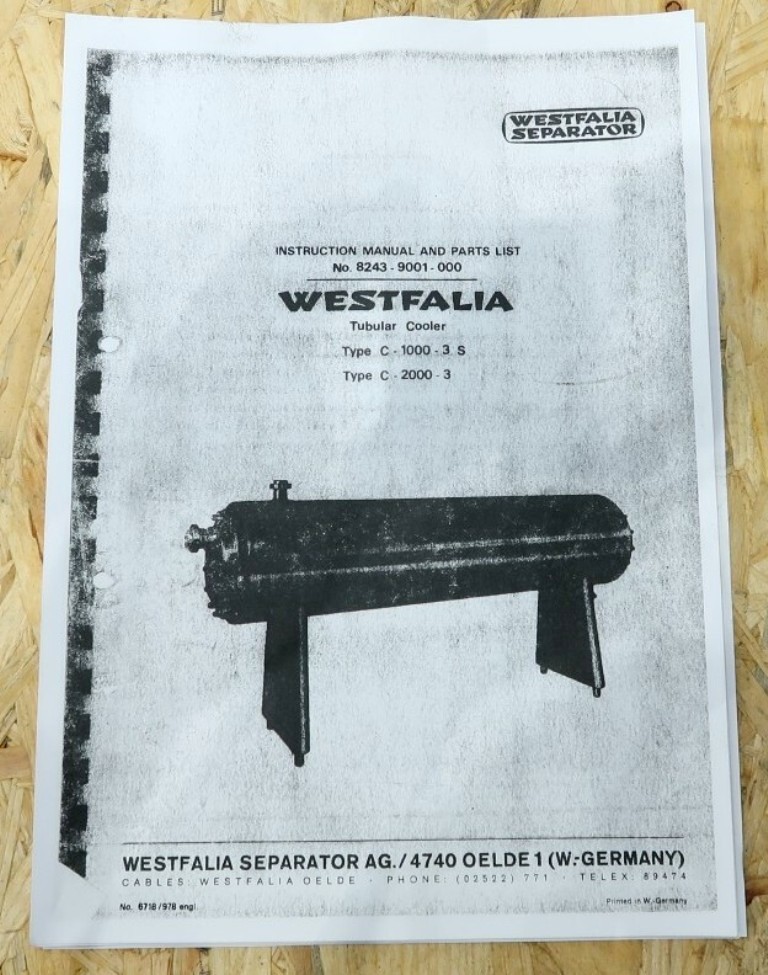

In addition to its impressive technical specifications, the Westfalia KDB 16-02-076 is designed with user convenience in mind. The integrated CIP (Clean-In-Place) system facilitates thorough cleaning and maintenance, ensuring hygiene standards are met without the need for disassembly. The accompanying Westfalia C1000 cooler, equipped with an 18.5 KW motor and sterile air filter, further enhances the system's efficiency by maintaining optimal temperatures during processing. The motor starter and PLC control panel, featuring variable frequency drives (VFDs) and a touch screen HMI, provide operators with intuitive control over the separator's functions, allowing for easy adjustments and monitoring of performance metrics. This equipment, manufactured in 2010 and in excellent condition, is a valuable asset for any dairy processing facility looking to enhance its production capabilities while maintaining high standards of quality and efficiency.

Key Features:

High-Speed Performance, Efficient Output Capacity, Integrated CIP System, Advanced Control Panel, Durable Stainless Steel Construction

Frequently Asked Questions

We're sorry, but this item has been sold.

Please consider the alternatives below.