Description:

Max bowl speed 3000 RPM, 3190 x G, 25 x 90" bowl ID. SS casings, eccentric liquid dams, hogged-out cake ports, 5" single lead polished conveyor, 125 HP motor 460/3/60/1780 RPM, 95:1 gearbox, 50 HP backdrive, CIP jogging motor, feed tube, guards, lube system, vibration isolators/switch and control panel, mounted on a stand with chutes, tank and pump. Excellent condition.

The Sharples P5400 sanitary decanter centrifuge, 316/317SS, is engineered for high-efficiency separation processes, making it an invaluable asset in various industrial applications. With a maximum bowl speed of 3000 RPM and a centrifugal force of 3190 x G, this decanter centrifuge is designed to handle substantial volumes while ensuring optimal separation of solids and liquids. The 25 x 90-inch bowl ID provides ample capacity for processing, while the stainless steel (SS) casings ensure durability and resistance to corrosion, making it suitable for sanitary applications where cleanliness and hygiene are paramount. The inclusion of eccentric liquid dams and hogged-out cake ports further enhances the efficiency of the separation process, allowing for effective discharge of solids and minimizing downtime for maintenance.

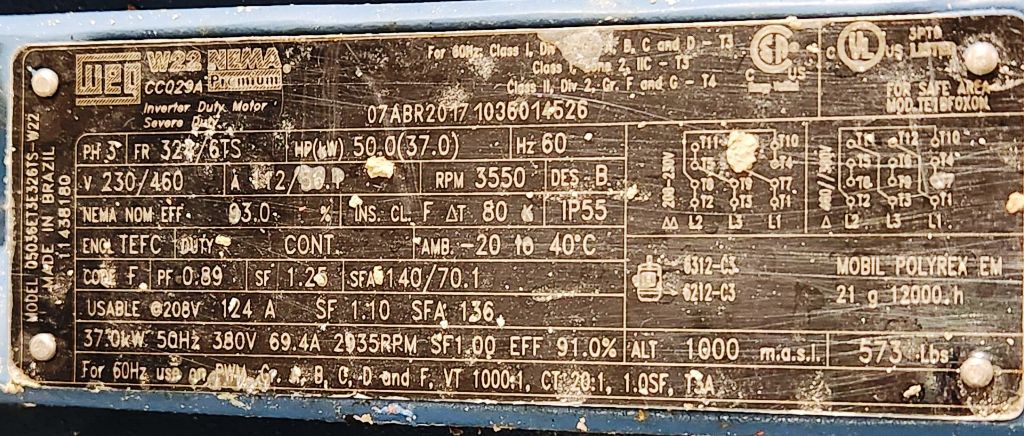

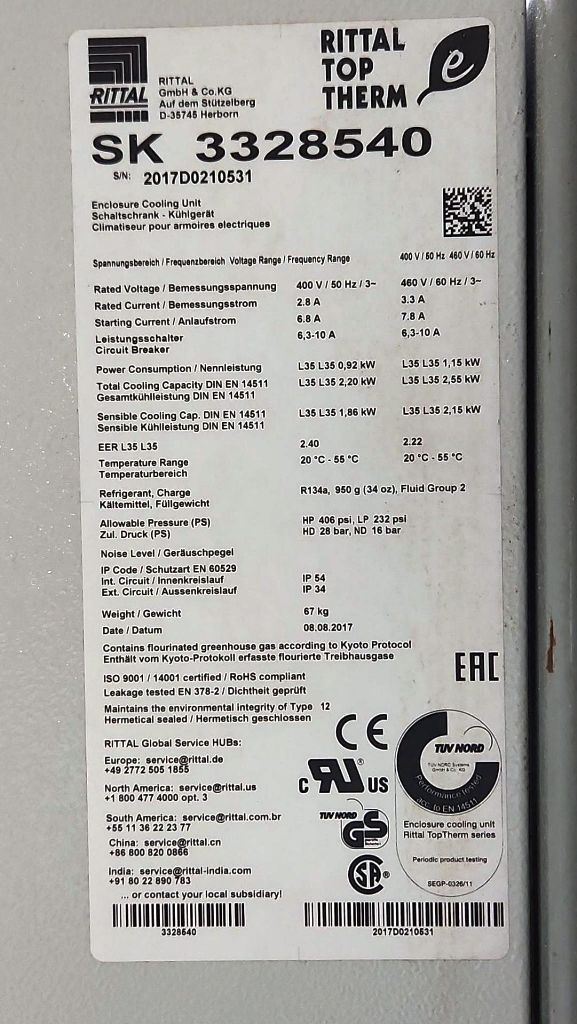

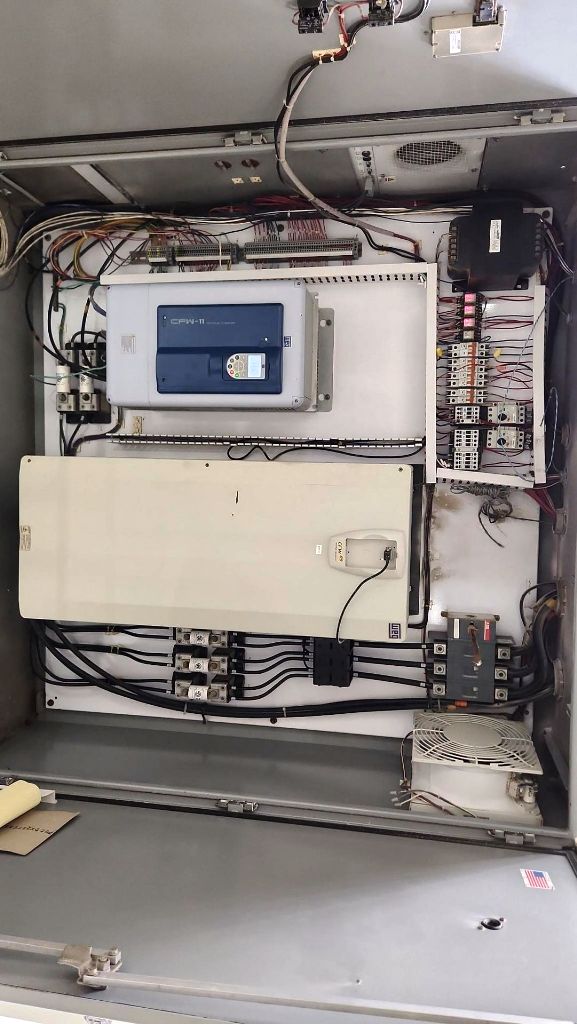

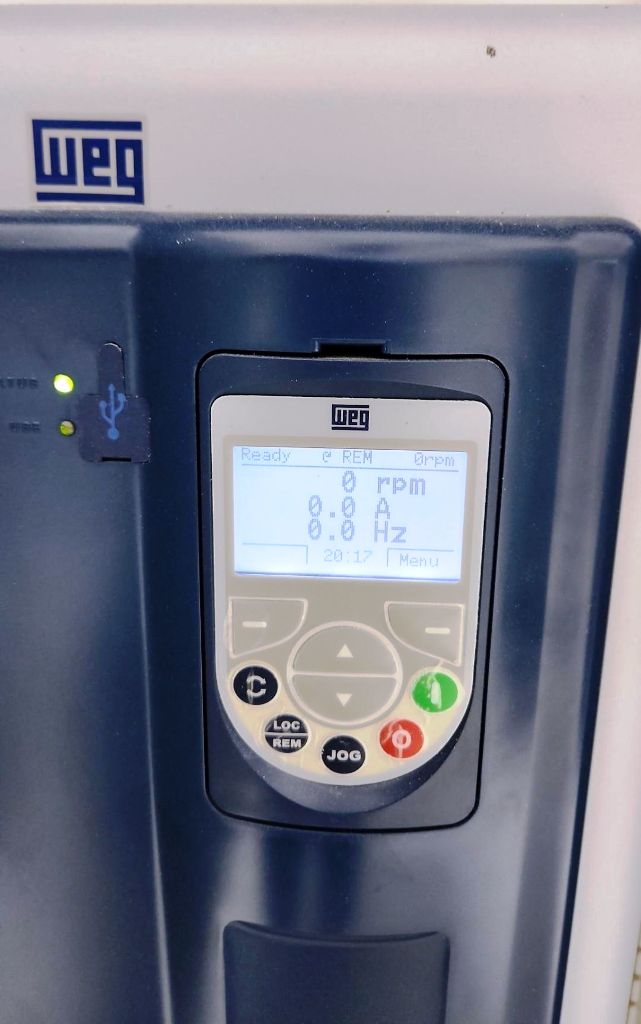

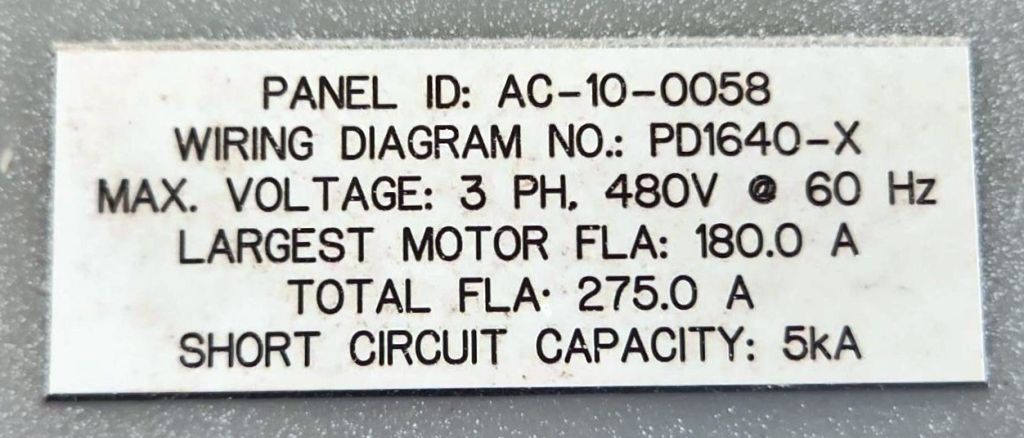

Equipped with a robust 125 HP motor operating at 460/3/60/1780 RPM, the Sharples P5400 ensures reliable performance under demanding conditions. The 95:1 gearbox and 50 HP backdrive facilitate smooth operation and control, while the CIP (Clean-In-Place) jogging motor simplifies maintenance, allowing operators to maintain hygiene standards without extensive disassembly. The unit also features a comprehensive lubrication system, vibration isolators, and a control panel that provides operators with the necessary tools to monitor and adjust performance parameters. Mounted on a sturdy stand with integrated chutes, tank, and pump, this centrifuge is designed for seamless integration into existing production lines, ensuring that your processes remain efficient and effective.

Key Features:

High-Speed Performance, Durable Construction, Efficient Separation, Robust Motor and Gearbox, User-Friendly Maintenance