Description:

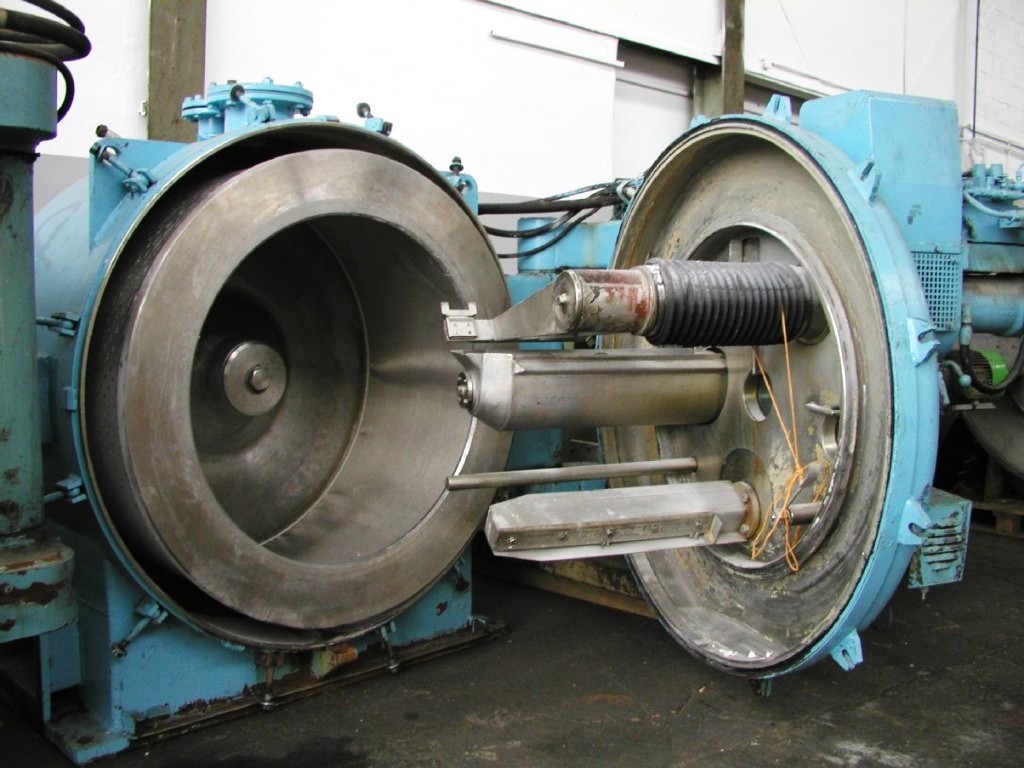

Max bowl speed 1220 RPM, 1050 x G, 1250 x 800mm basket ID, siphon design, 3.14 sqM filtration area, 410.9 L volume. 75 HP XP motor 460/3/60/1775 RPM, belt guards, feed and wash pipes, broad knife plow, discharge screw, gas purging of bearing seals, door interlock, speedometer, vibration monitor, hydraulic power pack and oil lubrication system. Prior use: Pharma. 1990 vintage. Very good condition.

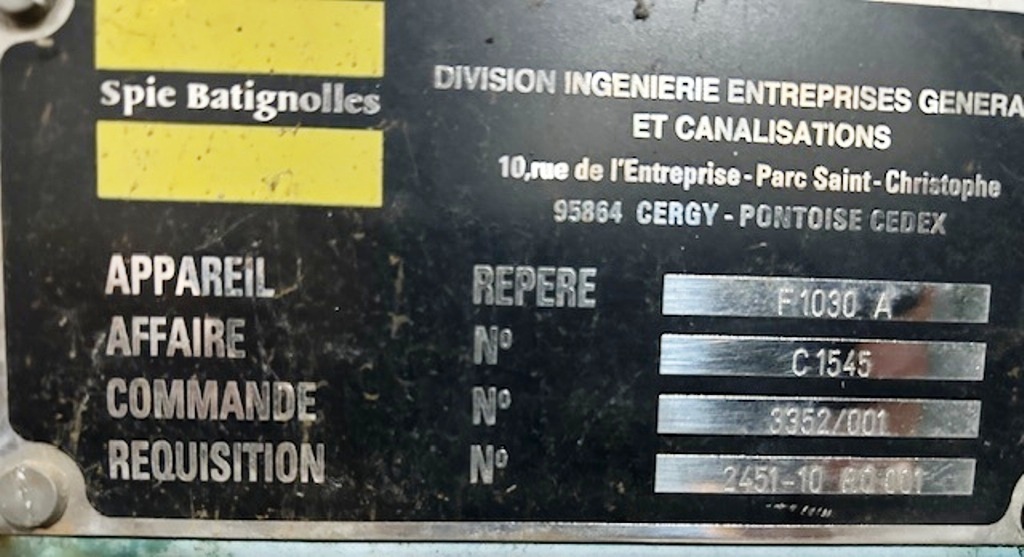

The Krauss-Maffei HZ 125/3.2 SiD peeler centrifuge, 316SS. is engineered for high-performance separation processes, particularly in the pharmaceutical industry. With a maximum bowl speed of 1220 RPM and a gravitational force of 1050 x G, this centrifuge is capable of efficiently separating solids from liquids, ensuring optimal product purity and yield. The spacious basket, measuring 1250 x 800mm in internal diameter, accommodates a substantial volume of material, with a filtration area of 3.14 square meters that enhances the centrifuge's throughput capabilities. The siphon design further contributes to effective liquid discharge, minimizing retention and maximizing operational efficiency during batch processing.

Equipped with a robust 75 HP XP motor, the Krauss-Maffei HZ 125/3.2 SiD operates at 460V, 3-phase, 60Hz, with a rated speed of 1775 RPM. This powerful motor ensures consistent performance under demanding conditions, while features such as belt guards, feed and wash pipes, and a broad knife plow facilitate seamless operation and maintenance. The discharge screw is designed to efficiently remove solids from the basket, while the gas purging of bearing seals enhances the longevity of the equipment. Safety is paramount, and the door interlock system, speedometer, and vibration monitor provide essential safeguards during operation. The hydraulic power pack and oil lubrication system further ensure that the centrifuge operates smoothly, reducing wear and tear and extending the lifespan of the machine. Despite its 1990 vintage, this unit is in very good condition, making it a reliable choice for businesses looking to enhance their processing capabilities.

Key Features:

High-Speed Performance, Durable Construction, Efficient Solid-Liquid Separation, Enhanced Safety Features, Low Maintenance Requirements