Description:

Max bowl speed 1500 RPM, 792 x G, 630 x 315mm basket ID, bottom dump, filtration area 0.63 sqM, 50 L volume, max load 63 kg. 5.5 KW XP motor 400/3/50/1440 RPM, plow, hydraulic drive for plow and cover, feed and rinse tubes, sight glass, tri-clamp fittings for top cover and cake discharge chute. 1995 vintage. Excellent condition. Located in Europe.

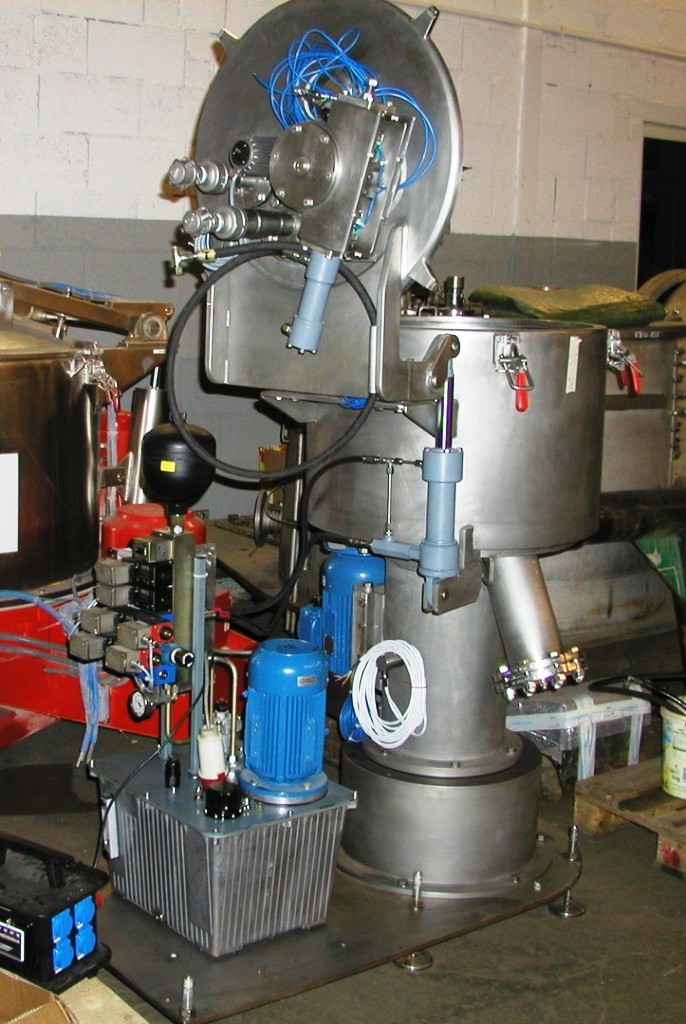

The GFT V 63-U perforate basket centrifuge, Hastelloy C22, is engineered for high-efficiency solid-liquid separation processes, making it an ideal choice for various industrial applications. With a maximum bowl speed of 1500 RPM and a centrifugal force of 792 x G, this centrifuge is capable of handling demanding separation tasks with precision. The generous basket dimensions of 630 x 315 mm and a filtration area of 0.63 square meters ensure that it can accommodate significant volumes of material, with a maximum load capacity of 63 kg. This robust design not only enhances throughput but also optimizes the quality of the separated solids and liquids, ensuring that operational efficiency is maintained throughout the process. The bottom dump configuration allows for easy discharge of the cake, minimizing downtime and maximizing productivity in your operations.

Equipped with a powerful 5.5 KW XP motor operating at 400/3/50/1440 RPM, the GFT V 63-U is designed for reliability and performance. The hydraulic drive system for the plow and cover ensures smooth operation and easy adjustments, allowing for optimal processing conditions. Additionally, the inclusion of feed and rinse tubes enhances the versatility of this centrifuge, enabling effective cleaning and maintenance procedures. The sight glass provides operators with a clear view of the separation process, facilitating real-time monitoring and adjustments as necessary. The use of tri-clamp fittings for the top cover and cake discharge chute further simplifies the maintenance process, ensuring that the equipment can be serviced quickly and efficiently. With its vintage from 1995, this centrifuge has been maintained in excellent condition, making it a valuable addition to any industrial facility looking to enhance its separation capabilities.

Key Features:

High-Speed Performance, Durable Construction, Easy Maintenance, Versatile Applications, Efficient Solid-Liquid Separation