Description:

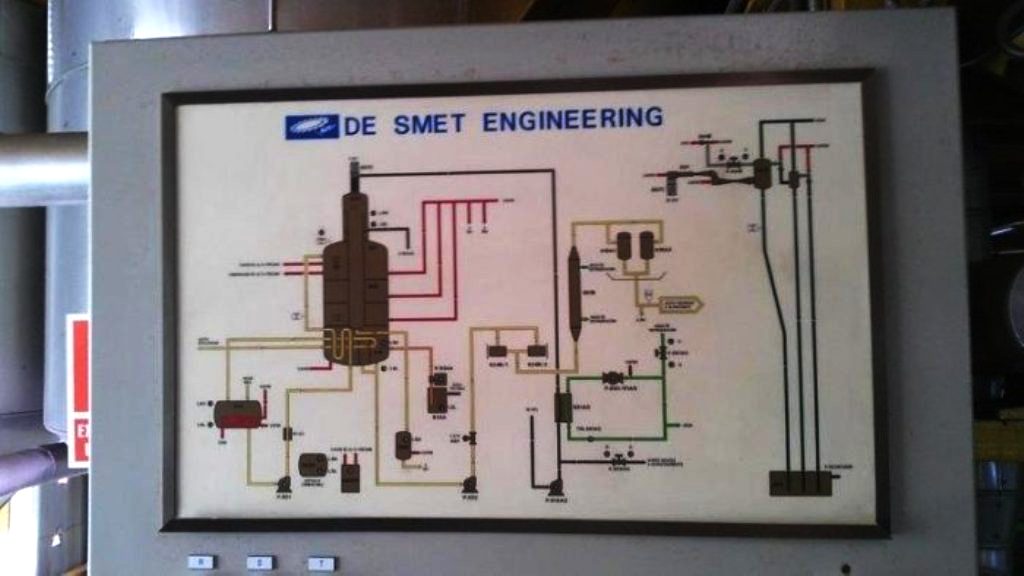

Used edible oil refinery built 2013 and shut down in 2017. Includes the following sections / equipment: – (3) GEA Westfalia separators (types RSE 90, RSE 170 and RTC 150) with combined capacity approximately 200 tons/day. – Desmet distillation, bleaching filter, deodorization. – Cooling towers, chillers, boilers, metal structure (which is reportedly simple to dismantle and reassemble again). – Steam generator with capacity 2500 kg/hour. – Reverse osmosis water treatment system. – (4) oil tanks (500,000 kg each), (2) have heating system and agitation. – (6) stainless steel tanks with capacity of 90,000 litres each for final product. – Vulcano Sadeca OMNIVAP 2.5 steam boiler with power 1,500,000 Kcal/h, steam 2,500 kg/h, pressure 13kg/cm3. Fueled by gasoil. The plant can refine oils with waxes (sunflower, corn, avocado) and oils without waxes (rapeseed, soya, olive), and the plant capacity depends on oil type. For standard oils with waxes capacity is approximately 60 tons/day. For oils without waxes the capacity is approximately 100 tons/day. Excellent condition. FCA Europe.

The GEA Westfalia 60-100 TPD edible oil refinery is a robust and versatile facility designed for the efficient processing of various edible oils. Built in 2013 and operational until 2017, this refinery features advanced technology that allows for the refinement of both waxy and non-waxy oils, including sunflower, corn, avocado, rapeseed, soya, and olive oils. The plant's capacity is adaptable, with a processing capability of approximately 60 tons per day for oils containing waxes and up to 100 tons per day for those without. This flexibility makes the refinery an ideal choice for businesses looking to diversify their product offerings or optimize their operations based on market demand. The equipment included in this refinery is of high quality, ensuring that the end product meets stringent industry standards for purity and quality.

The refinery is equipped with three GEA Westfalia separators (types RSE 90, RSE 170, and RTC 150), which collectively provide a combined capacity of around 200 tons per day. This high throughput is complemented by essential components such as a Desmet distillation unit, bleaching filter, and deodorization system, all of which are crucial for producing high-grade edible oils. Additionally, the facility includes a steam generator capable of producing 2,500 kg/hour, along with a reverse osmosis water treatment system that ensures the quality of water used in the refining process. The presence of multiple stainless steel tanks, each with a capacity of 90,000 liters, allows for the effective storage of the final product, while the four oil tanks, each holding 500,000 kg, are equipped with heating systems and agitation to maintain optimal conditions for oil storage.

The GEA Westfalia 60-100 TPD edible oil refinery is not only efficient but also designed for ease of maintenance and operation. The metal structure of the plant is reportedly simple to dismantle and reassemble, making it a practical choice for companies considering relocation or expansion. With its excellent condition and FCA Europe status, this refinery represents a significant investment opportunity for businesses in the edible oil industry looking to enhance their production capabilities with a reliable and high-performance facility.

Key Features:

High Processing Capacity, Versatile Oil Processing, Advanced Separation Technology, Efficient Storage Solutions, Easy Maintenance and Relocation

Frequently Asked Questions

We're sorry, but this item has been sold.

Please consider the alternatives below.