Description:

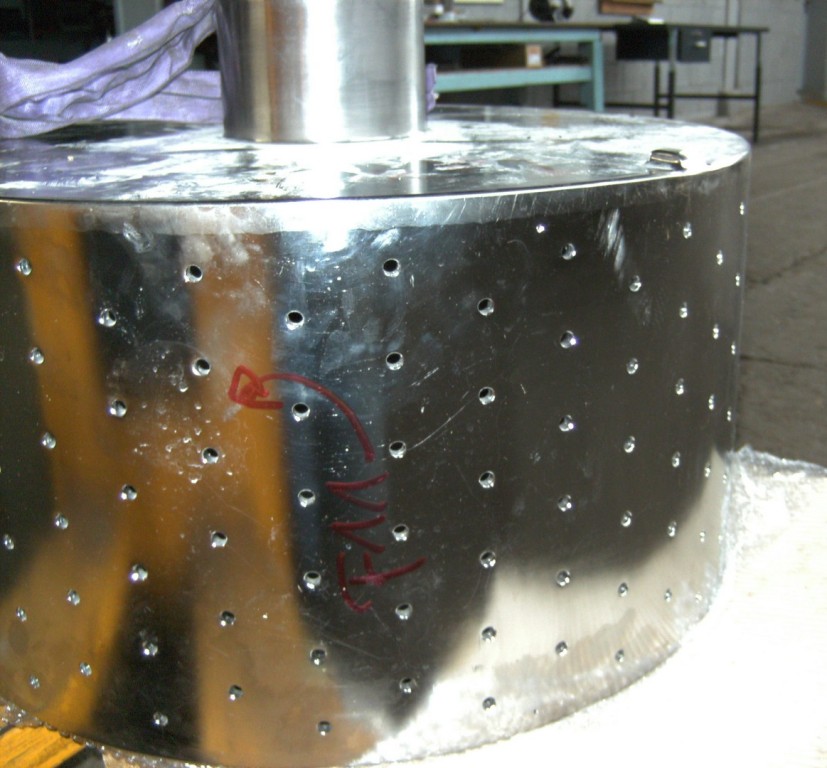

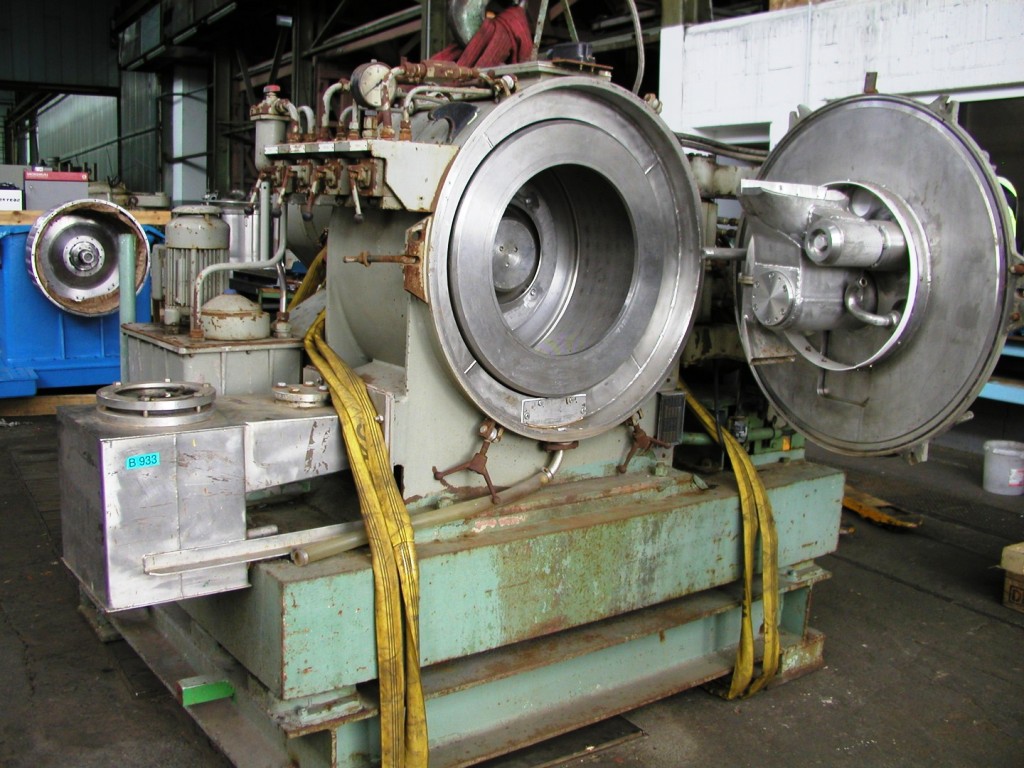

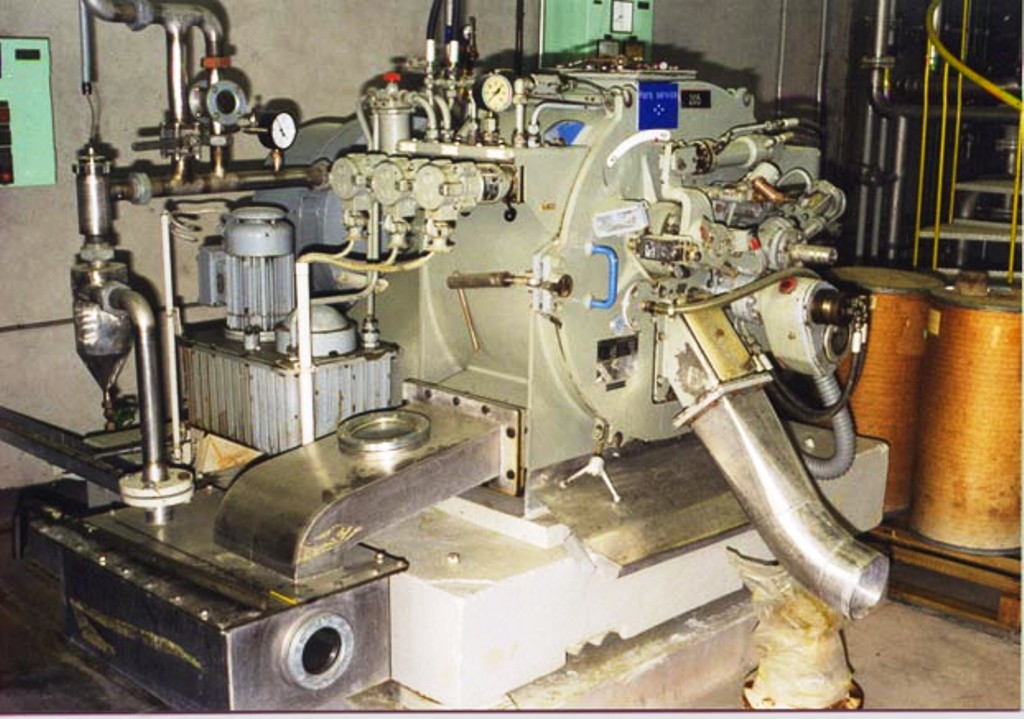

Max bowl speed 2400 RPM, 2028 x G, 0.63 sqM filtration area, 41 L volume, 51 kg max load, gas tight casing to 1 bar, clean room design cGMP. 7.5 KW XP motor 400/3/50/1460 RPM, belt guards, feed and wash pipes, broad knife plow with pneumatic heel cake removal system and solids discharge via PFTE lined chute. CIP system, door lock switch, pneumatic feed control unit, XP hydraulic control unit with connections for Ni purge and filtrate outlet with compensator and all technical documentation. 1998 vintage. Excellent condition. Located in Europe.

The Ferrum HSZ-Ph 630/320 peeler centrifuge, Hastelloy, is engineered for high-performance separation processes, making it an ideal choice for industries requiring stringent cleanliness and efficiency standards. With a maximum bowl speed of 2400 RPM and a gravitational force of 2028 x G, this centrifuge excels in separating solids from liquids, ensuring optimal product recovery and minimal waste. The unit features a generous filtration area of 0.63 square meters and a volume capacity of 41 liters, allowing for substantial processing of materials while maintaining high throughput rates. Its robust construction includes a gas-tight casing capable of withstanding pressures up to 1 bar, making it suitable for applications that demand a controlled environment, such as pharmaceutical and biotech industries. The clean room design adheres to current Good Manufacturing Practices (cGMP), ensuring compliance with regulatory standards and enhancing product safety.

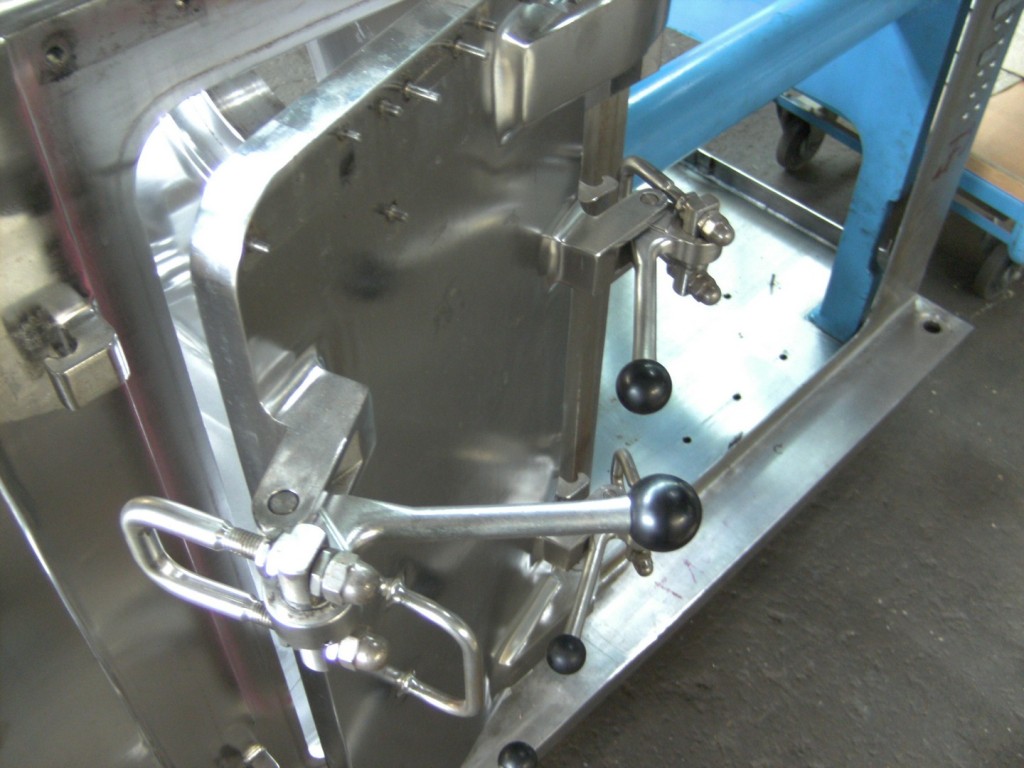

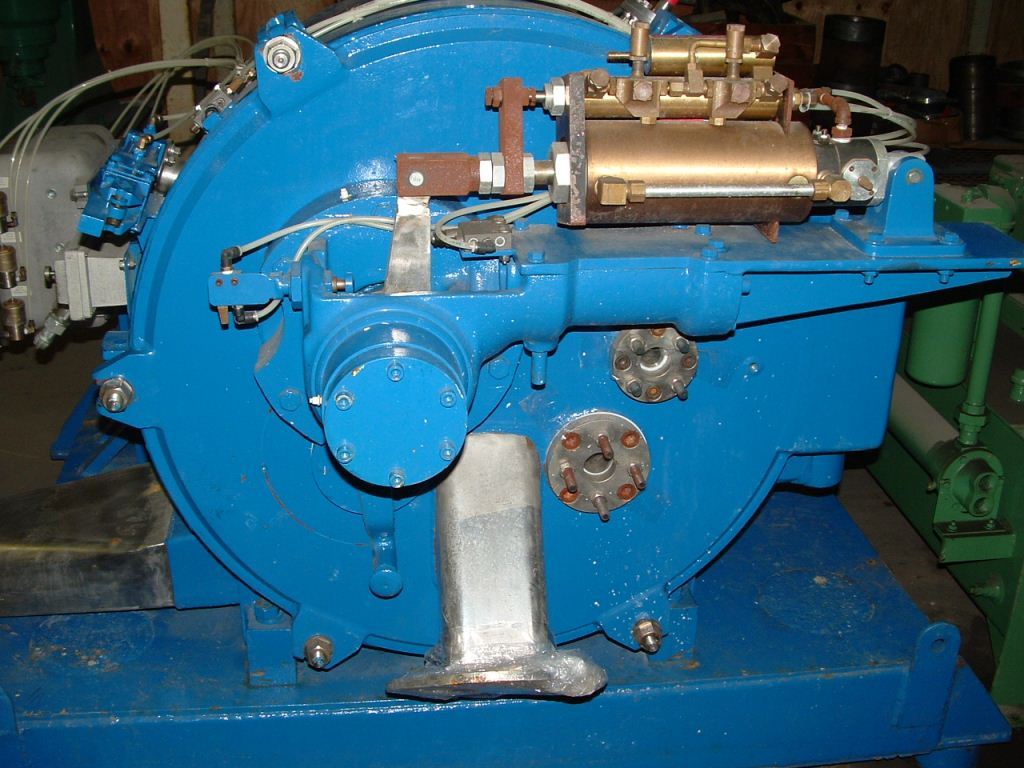

Equipped with a powerful 7.5 kW XP motor, the Ferrum HSZ-Ph 630/320 operates efficiently at 400/3/50/1460 RPM, providing reliable performance even under demanding conditions. Safety features such as belt guards and a door lock switch enhance operational safety, while the pneumatic feed control unit allows for precise material handling. The innovative broad knife plow with a pneumatic heel cake removal system ensures effective cake discharge, while the PFTE lined chute minimizes wear and tear during solids discharge. Additionally, the integrated Clean-In-Place (CIP) system simplifies maintenance and cleaning processes, reducing downtime and enhancing productivity. This centrifuge is a vintage model from 1998, yet it remains in excellent condition, demonstrating the durability and longevity of Ferrum's engineering. Located in Europe, this unit is ready to be integrated into your production line, providing a reliable solution for your separation needs.

Key Features:

High-Speed Performance, Durable Construction, Clean Room Design, Efficient Cake Discharge, Integrated CIP System