Description:

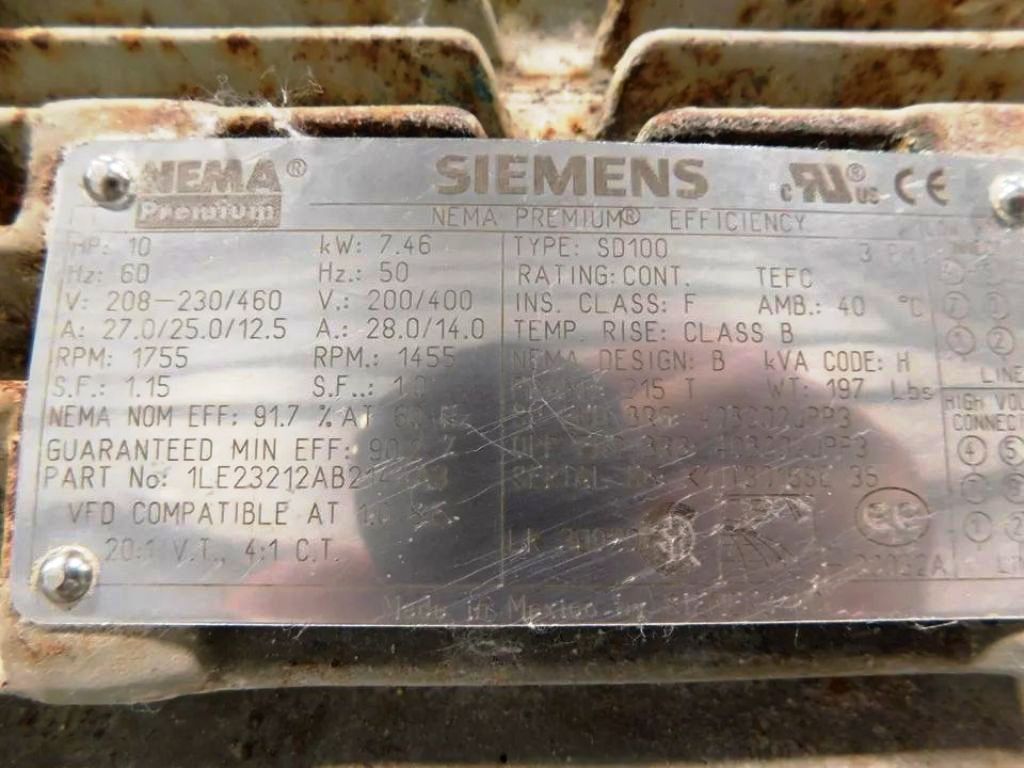

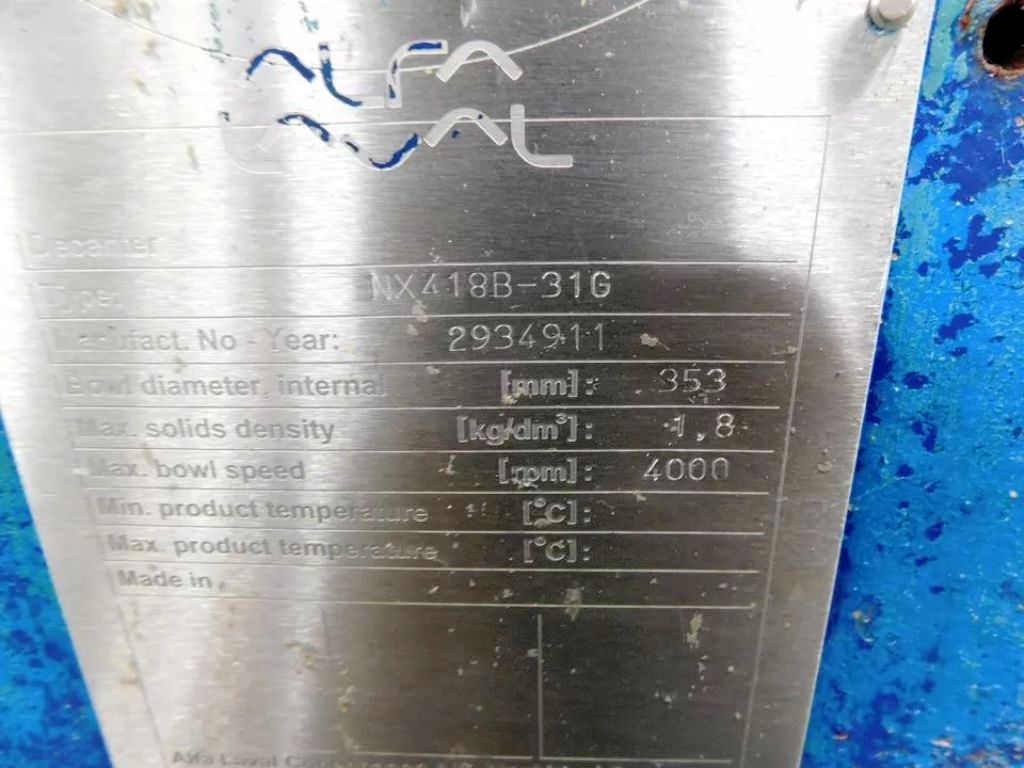

Max bowl speed 4000 RPM, 3158 x G, liquid discharged by gravity, 110mm hardsurfaced Esbjerg conveyor, 50 HP motor 230/460/3/60/1755 RPM, guards, 159:1 2.5 kNm gearbox, 10 HP backdrive, guards and feed tube, mounted on stand. Prior use: Starch and sweeteners. Very good condition.

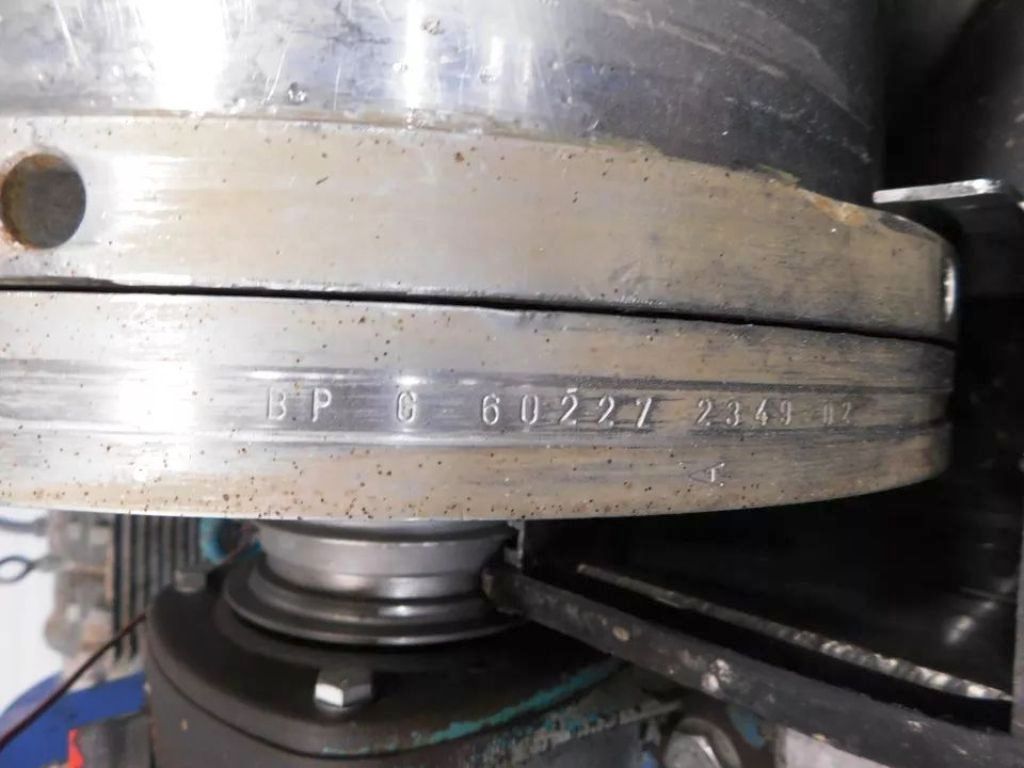

The Alfa-Laval NX 418B-31G decanter centrifuge, 316SS, is engineered for high-efficiency separation processes, making it an ideal choice for industries such as food processing, chemical production, and wastewater treatment. With a maximum bowl speed of 4000 RPM and a centrifugal force of 3158 x G, this centrifuge excels in separating solids from liquids, ensuring optimal performance in applications involving starch and sweeteners. The liquid discharge is facilitated by gravity, which enhances the operational efficiency and reduces the need for additional pumping systems. The robust design includes a 110mm hardsurfaced Esbjerg conveyor that effectively transports solids out of the bowl, minimizing wear and extending the lifespan of the equipment. The unit is powered by a 50 HP motor, capable of operating at 230/460V, 3-phase, 60Hz, and 1755 RPM, providing the necessary power to handle demanding separation tasks with ease.

Constructed from high-quality 316 stainless steel, the Alfa-Laval NX 418B-31G is built to withstand corrosive environments, ensuring durability and reliability over time. The gearbox features a 159:1 ratio with a 2.5 kNm capacity, allowing for smooth operation and precise control of the centrifuge's performance. Additionally, a 10 HP backdrive motor is included, which aids in maintaining consistent feed rates and enhances the overall efficiency of the separation process. Safety is also a priority, as the centrifuge comes equipped with guards and a feed tube, ensuring safe operation for personnel while minimizing the risk of contamination. Mounted on a sturdy stand, this centrifuge is designed for easy integration into existing production lines, making it a valuable asset for any industrial operation seeking to optimize their separation processes.

Key Features:

High-Speed Performance, Durable Construction, Efficient Solid-Liquid Separation, Safety Features, Versatile Applications