Description:

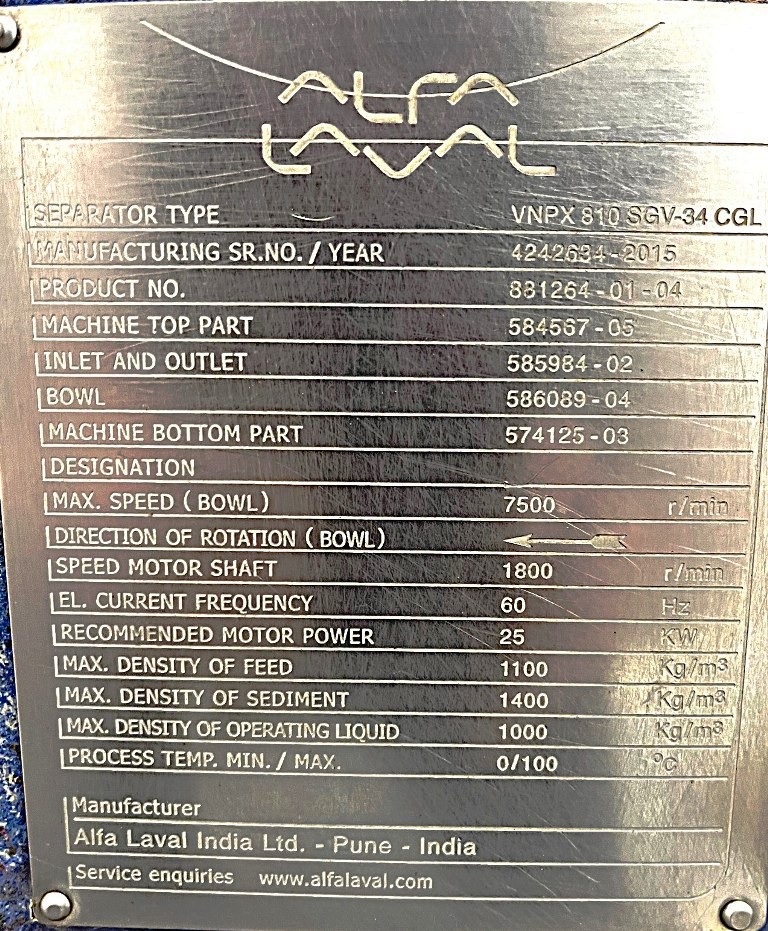

Max bowl speed 7500 RPM, rated @ 20,000 LPH, liquid discharged under pressure, low shear inlet design, Smart Eject self-triggering system, Oxy-Stop hydro-hermetic seal and jacketed hood. 25 KW motor 460/3/60/1800 RPM with VFD, sludge cyclone, flow meter, valves, piping, 3.5 KW feed pump motor, 4 KW solids pump motor, tools and PLC control panel, unitized on a SS skid. Prior use: Pea protein isolate. 2015 vintage. Excellent working condition. aka VNPX 810-SGV-34CGL. Located in Mexico.

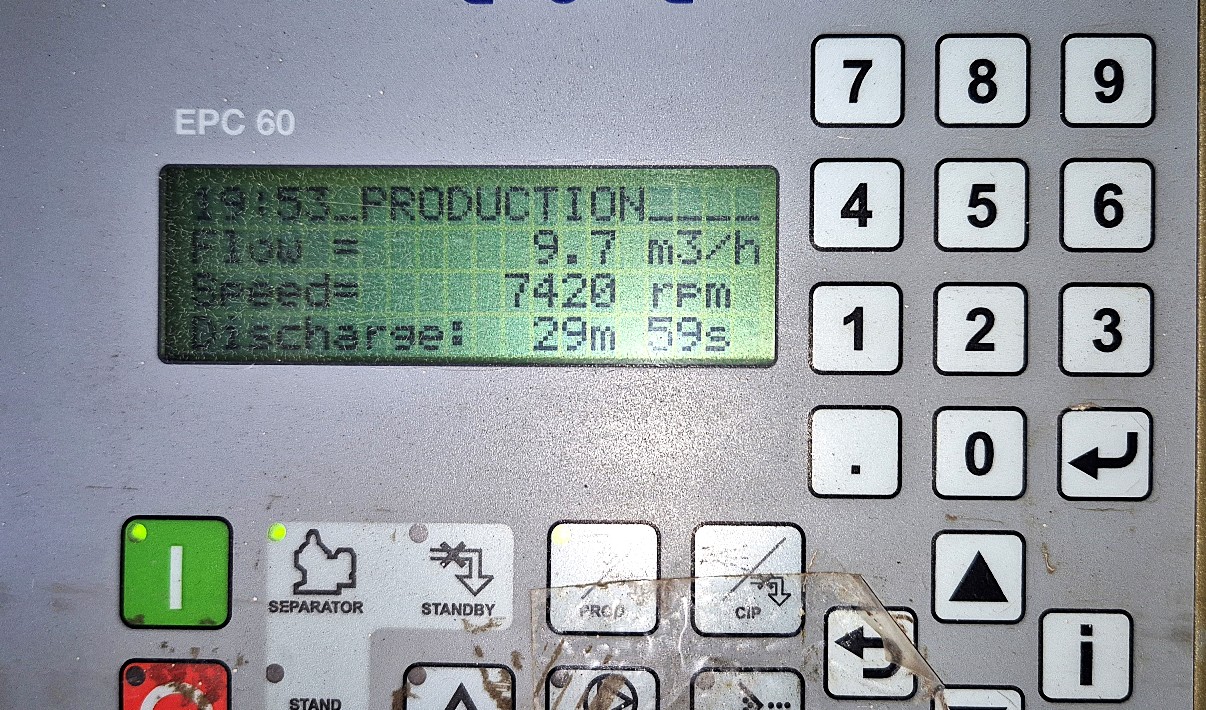

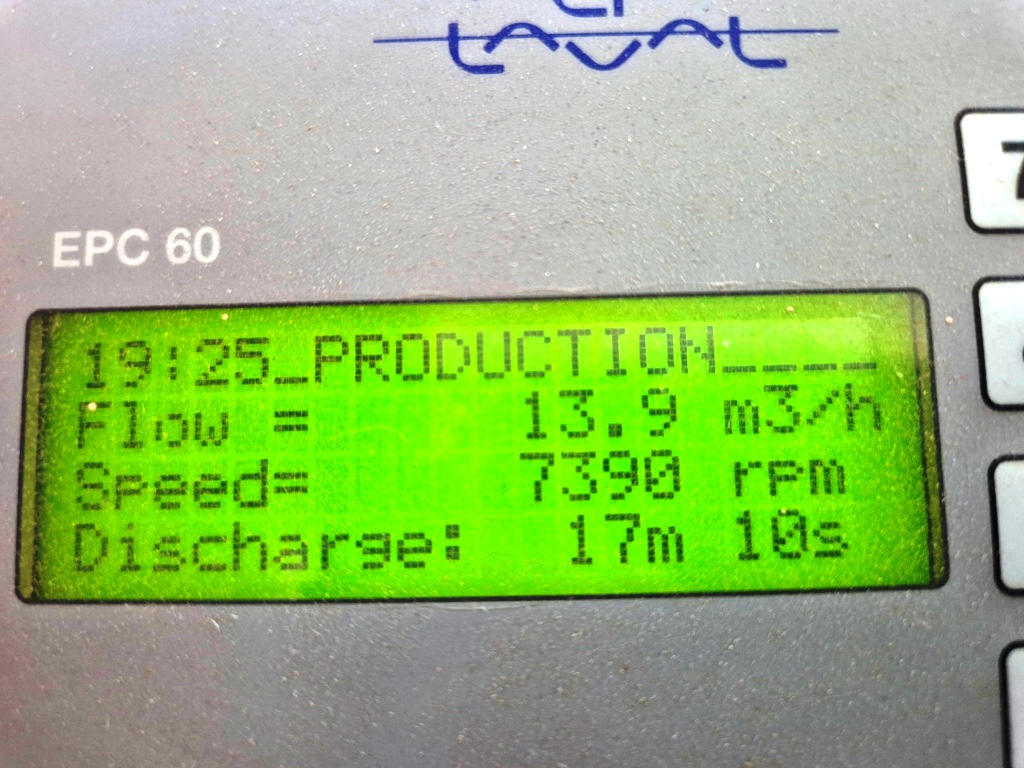

The Alfa-Laval CLARA 200 hermetic clarifier module, 316SS, is engineered for high-efficiency separation processes, making it an ideal choice for industries requiring precise liquid-solid separation. With a maximum bowl speed of 7500 RPM and a rated capacity of 20,000 liters per hour (LPH), this clarifier is designed to handle substantial volumes while maintaining optimal performance. The low shear inlet design ensures that the integrity of the feed material is preserved, making it particularly suitable for sensitive applications such as the processing of pea protein isolate. The unit is equipped with a Smart Eject self-triggering system, which enhances operational efficiency by automating the discharge process, thereby reducing downtime and labor costs associated with manual interventions.

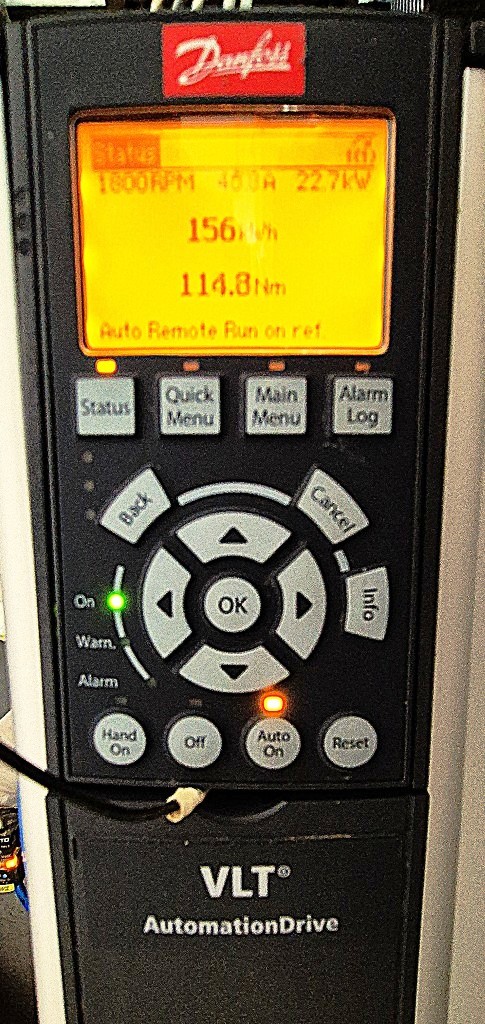

The Alfa-Laval CLARA 200 also features an Oxy-Stop hydro-hermetic seal and a jacketed hood, which work together to maintain a controlled environment within the clarifier, minimizing the risk of contamination and ensuring product quality. The robust construction of the unit, utilizing 316 stainless steel, provides excellent corrosion resistance and durability, making it suitable for a variety of industrial applications. The system is powered by a 25 KW motor operating at 460V, 3-phase, 60 Hz, and 1800 RPM, complete with a Variable Frequency Drive (VFD) for precise speed control. Additionally, the inclusion of a sludge cyclone, flow meter, valves, and piping enhances the functionality of the system, allowing for seamless integration into existing production lines. The unitized design on a stainless steel skid facilitates easy installation and mobility, making it a practical choice for facilities looking to optimize their processing capabilities.

Key Features:

High-Speed Performance, Durable Construction, Automated Discharge System, Efficient Liquid-Solid Separation, Easy Installation and Mobility