Description:

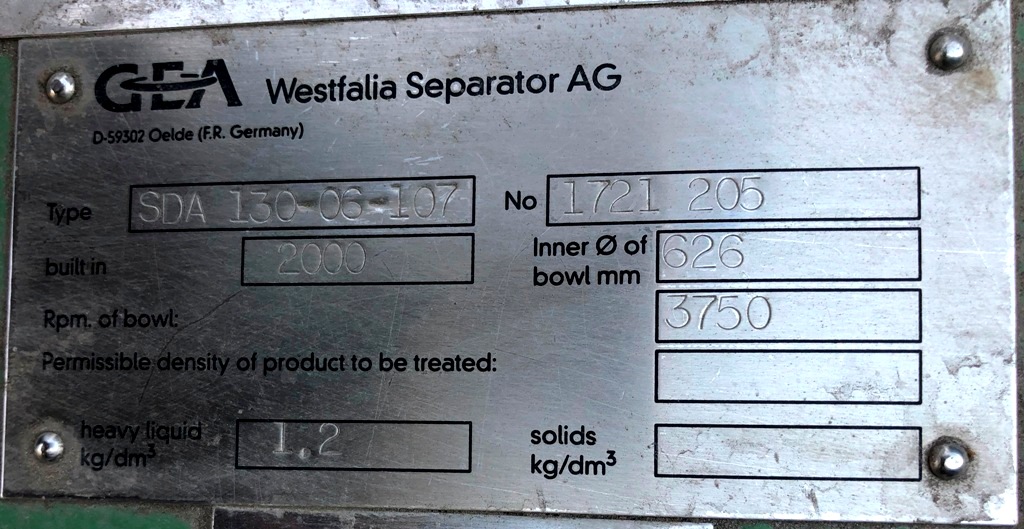

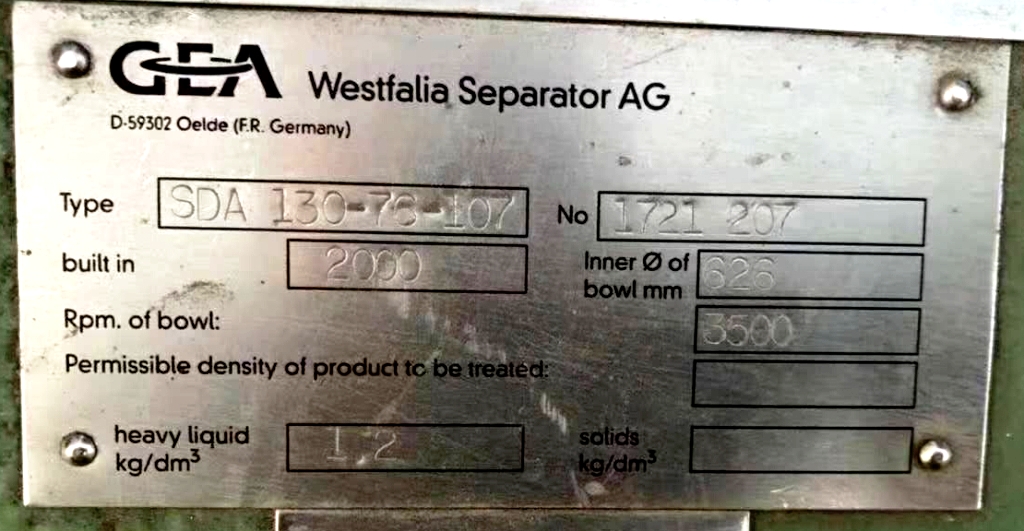

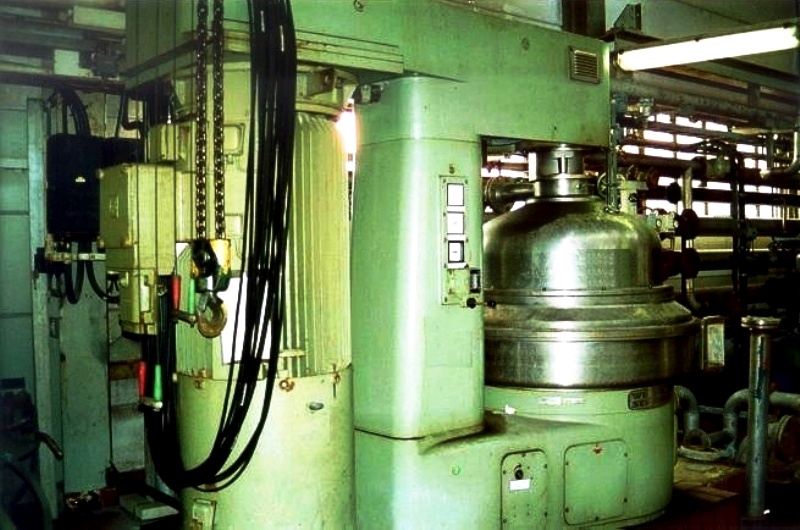

Max bowl speed 4500 RPM, rated @ 250 CMPH, liquid phase discharged under pressure, concentrated starch discharged into solids vessel; one with wash water feature, one without, 132 KW motor 380/3/50/3000 RPM. No tools or controls. 2000 vintage. Very good condition. Located in China.

The Westfalia SDA 130-76-107 nozzle centrifuge, 316SS. is engineered to deliver exceptional performance in the separation of liquids and solids, making it an ideal choice for various industrial applications, particularly in the food and beverage, chemical, and pharmaceutical sectors. With a maximum bowl speed of 4500 RPM and a rated capacity of 250 CMPH, this centrifuge is designed to efficiently handle high volumes of material while ensuring optimal separation efficiency. The liquid phase is discharged under pressure, allowing for a continuous operation that minimizes downtime and enhances productivity. The design includes two solids vessels, one equipped with a wash water feature, which facilitates the cleaning process and ensures that the concentrated starch is effectively discharged, maintaining the quality of the final product.

Constructed from 316 stainless steel, the Westfalia SDA 130-76-107 nozzle centrifuge is built to withstand the rigors of industrial use while providing excellent corrosion resistance. This robust construction not only extends the lifespan of the equipment but also ensures compliance with stringent hygiene standards, making it suitable for applications where cleanliness is paramount. The centrifuge is powered by a 132 KW motor operating at 380V/3/50/3000 RPM, providing the necessary torque and speed for efficient operation. Its vintage from 2000, combined with its very good condition, indicates that this unit has been well-maintained and is ready for immediate deployment in your facility. With no tools or complex controls required for operation, the Westfalia SDA 130-76-107 nozzle centrifuge is designed for ease of use, making it an excellent addition to any industrial processing line.

Key Features:

High-Speed Performance, Durable Construction, Efficient Liquid-Solid Separation, Easy Maintenance, Versatile Application