Description:

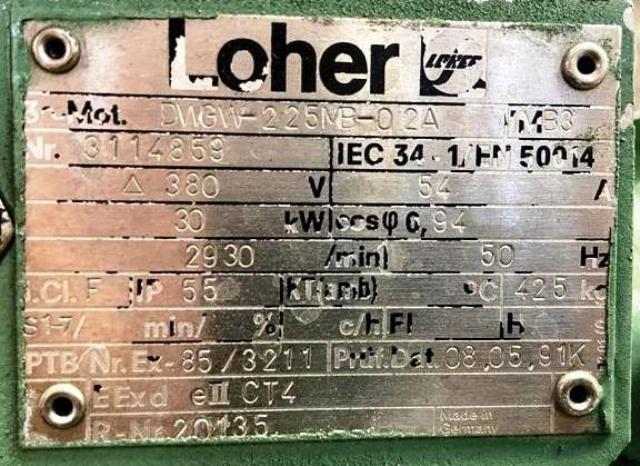

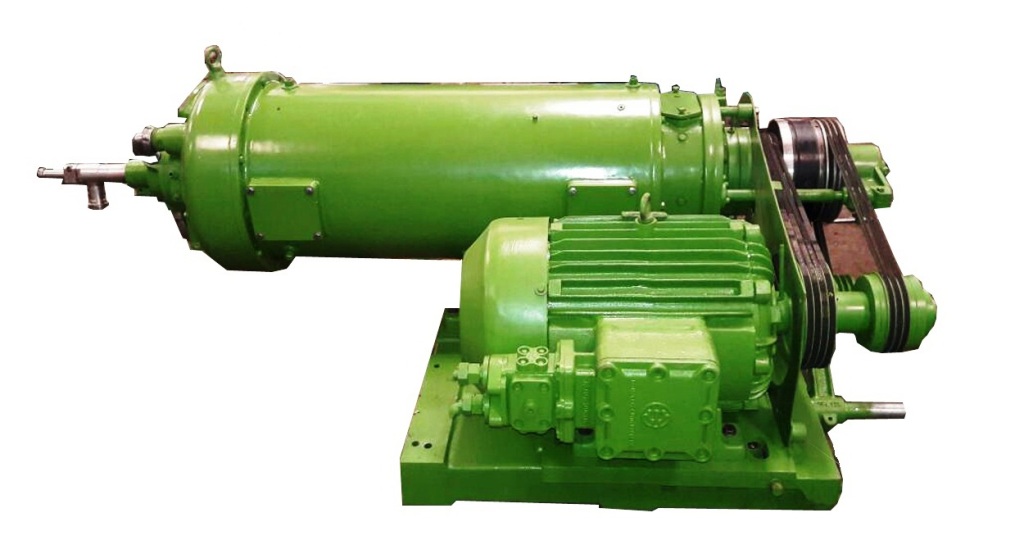

Max bowl speed 4000 RPM, rated @ 55 GPM, pressure discharge, gas-tight design, sleep angle beach. 30 KW motor 380/3/50/1450 RPM, cyclo gearbox, guards, feed tube and lube system. 1991 vintage. Very good condition. Located in Europe.

(2) Westfalia CA 366-29-00 extraction decanters, 316SS. are engineered for optimal performance in liquid-solid separation processes, making them an invaluable asset in various industrial applications. With a maximum bowl speed of 4000 RPM, these decanters are capable of handling a rated capacity of 55 gallons per minute (GPM), ensuring efficient extraction and processing of materials. The gas-tight design enhances safety by preventing the escape of vapors, while the steep angle beach design facilitates effective separation, allowing for higher throughput and reduced operational downtime. The robust 30 KW motor, operating at 380V/3/50Hz and 1450 RPM, is paired with a cyclo gearbox that provides reliable torque and speed control, making these decanters suitable for demanding environments. The inclusion of guards, a feed tube, and a lubrication system further enhances the operational reliability and maintenance ease of these machines.

Manufactured in 1991, these decanters have been well-maintained and are in very good condition, ready to be integrated into your production line. Their durable construction, made from high-quality 316 stainless steel, ensures resistance to corrosion and wear, which is crucial for industries dealing with aggressive chemicals or high temperatures. The design not only promotes longevity but also simplifies cleaning and maintenance, allowing for minimal downtime. Located in Europe, these decanters are an excellent choice for businesses looking to enhance their extraction processes with reliable, high-performance equipment. Investing in (2) Westfalia CA 366-29-00 extraction decanters means securing a dependable solution that can significantly improve your operational efficiency and product quality.

Key Features:

High-Speed Performance, Durable Construction, Gas-Tight Design, Efficient Liquid-Solid Separation, Easy Maintenance