Description:

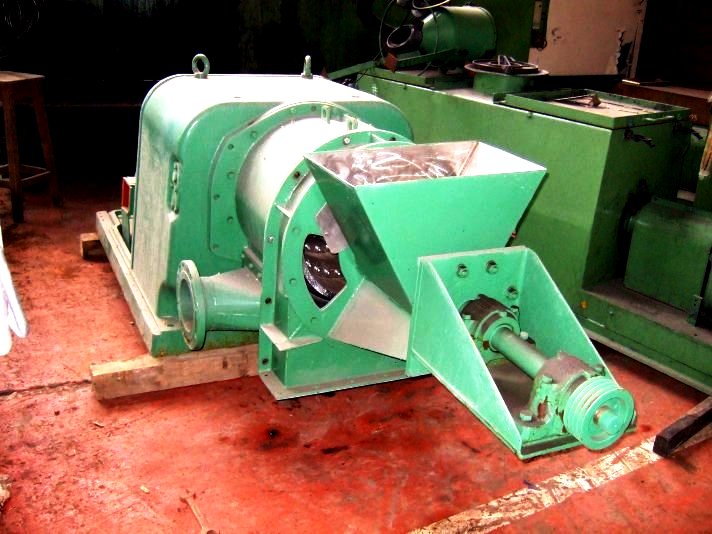

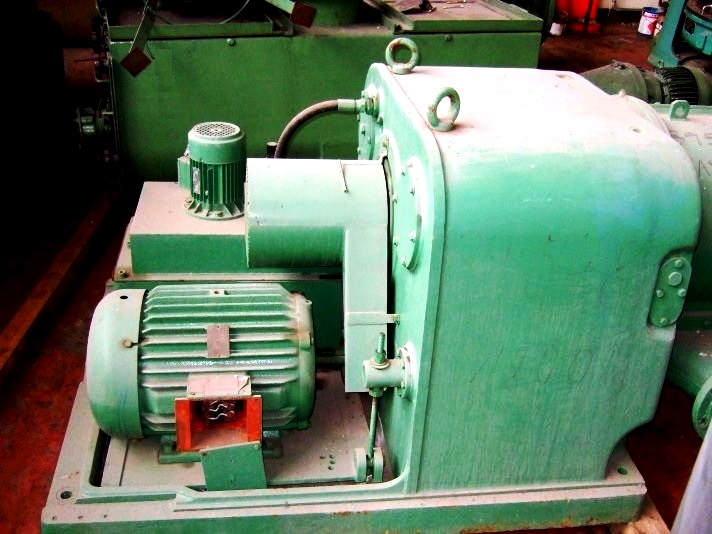

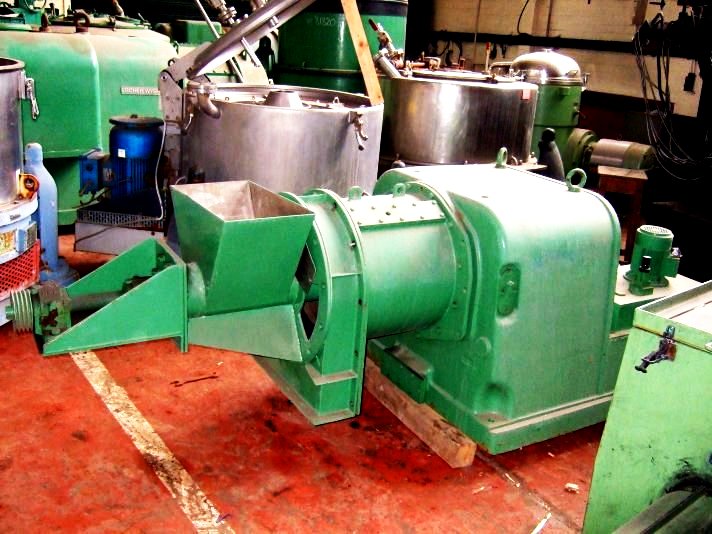

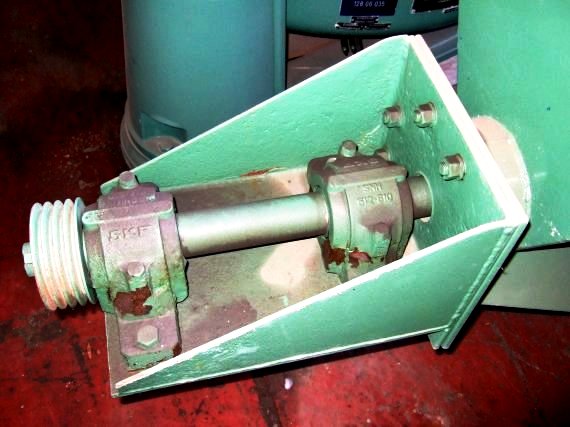

400mm/330mm bowl diameter, rubber-lined casing, 22 KW motor 415/3/50/1450 RPM, screw conveyor feed, wash and rinse tubes, unitized on inertia base with vibration isolators. Reconditioned with mechanical warranty. Located in UK.

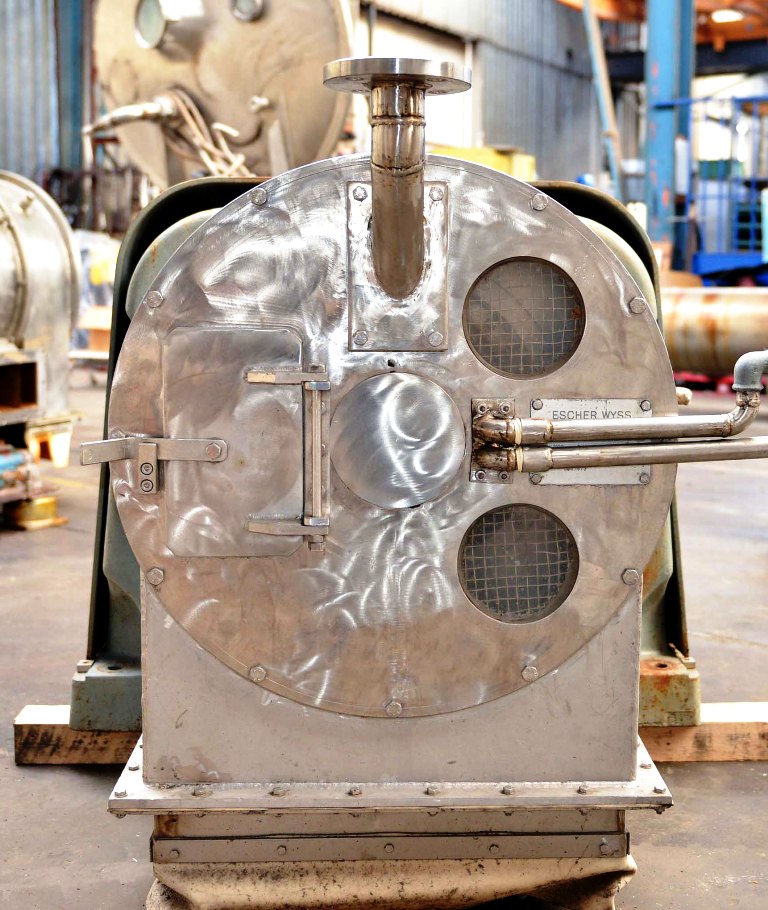

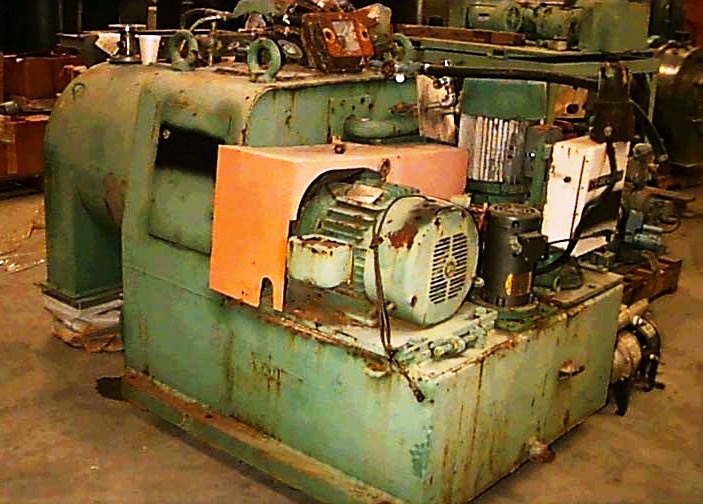

The (2) Escher-Wyss P-3 2-stage pusher centrifuges, Hastelloy C. are engineered for high-performance separation processes, making them ideal for various industrial applications. With a bowl diameter of 400mm and 330mm, these centrifuges are designed to efficiently handle a wide range of materials, ensuring optimal separation and clarity of the final product. The robust construction features a rubber-lined casing, which not only enhances durability but also provides protection against corrosive substances, making them suitable for challenging environments. Powered by a 22 KW motor operating at 415/3/50/1450 RPM, these centrifuges deliver consistent and reliable performance, ensuring that your production processes remain uninterrupted and efficient.

Equipped with a screw conveyor feed system, the (2) Escher-Wyss P-3 centrifuges facilitate smooth and continuous material input, which is crucial for maintaining operational efficiency. The inclusion of wash and rinse tubes further enhances the usability of these machines, allowing for thorough cleaning between batches and minimizing downtime. The unitized design, mounted on an inertia base with vibration isolators, ensures stability during operation, reducing wear and tear on the equipment and extending its lifespan. These centrifuges have been reconditioned and come with a mechanical warranty, providing peace of mind to buyers regarding their investment. Located in the UK, they are readily available for industries looking to enhance their separation capabilities with reliable and high-quality equipment.

Key Features:

High-Speed Performance, Durable Construction, Efficient Material Handling, Easy Maintenance, Stable Operation