Description:

Max bowl speed 2600 RPM, 2229 x G, 598 x 2020mm, 23.54 x 79.53" bowl ID. High volume design for very low gravity solids (LGS) and barite recovery. Hydraulic capacity 792 GPM (180 m3/h), max solids discharge rate 125 GPM (28.5 m3/h). 6 degree beach angle, 150mm, 5.9" single lead STC-tiled 304SS conveyor, 132 KW XP motor 400/460/3/50/60, hydraulic main drive and backdrive, 80:1 11 kNm gearbox, guards, feed tube, bearing lube system, vibration switch/isolators and chutes with PLC controls and ancillary tanks, pumps on skid-mounted base. 2012 vintage. Very good condition. Located in UK.

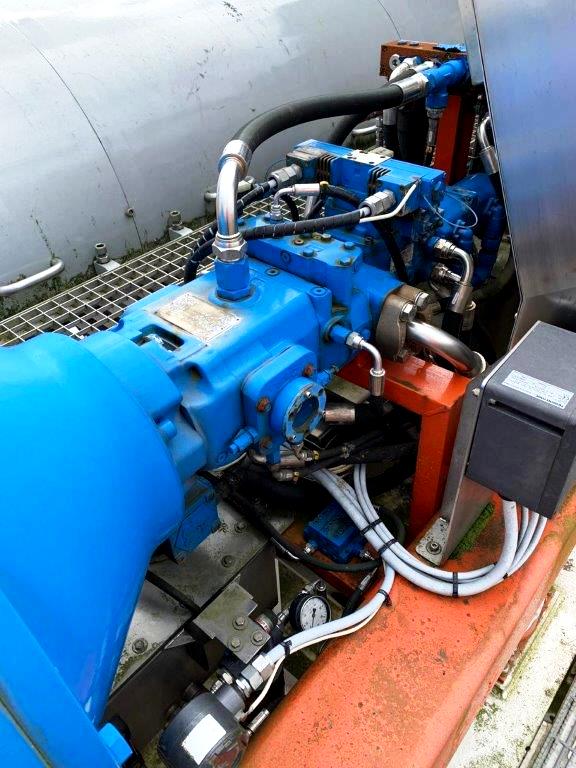

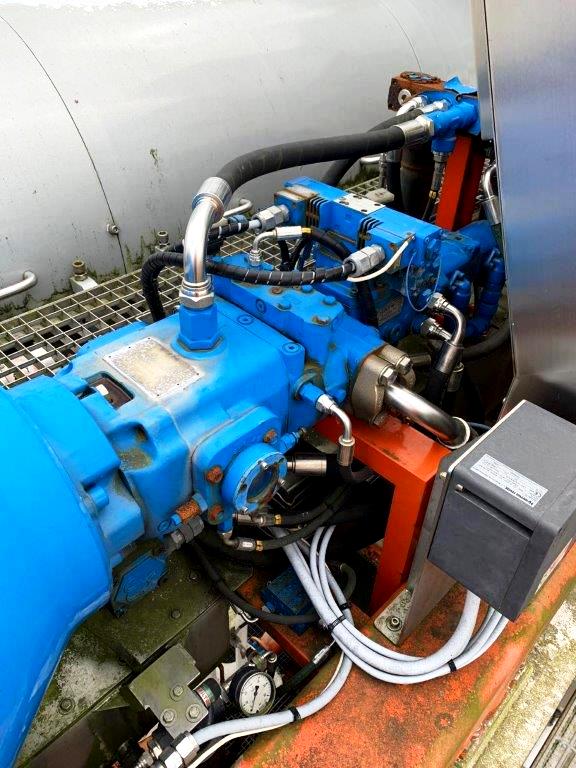

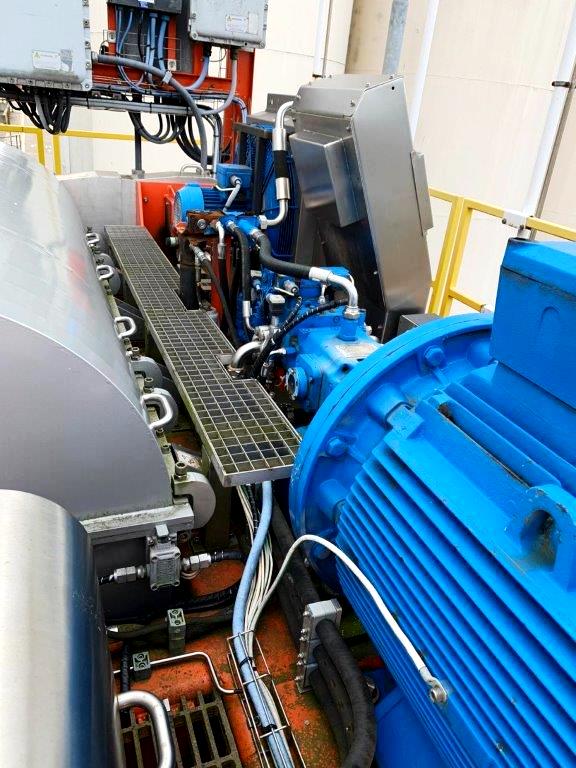

The (2) Swaco CD 600 FH drilling mud centrifuges, A890 duplex SS, are engineered for high-performance separation of drilling fluids, specifically designed to handle very low gravity solids (LGS) and facilitate efficient barite recovery. With a maximum bowl speed of 2600 RPM and a centrifugal force of 2229 x G, these centrifuges are capable of achieving exceptional separation efficiency. The dimensions of the bowl, measuring 598 x 2020mm (23.54 x 79.53 inches), provide a high-volume design that is crucial for operations requiring rapid processing of drilling mud. The hydraulic capacity of 792 GPM (180 m³/h) ensures that these centrifuges can manage significant volumes of fluid, while the maximum solids discharge rate of 125 GPM (28.5 m³/h) allows for effective removal of solids, thereby maintaining optimal fluid properties throughout the drilling process.

In addition to their impressive performance specifications, the (2) Swaco CD 600 FH centrifuges are equipped with a variety of features that enhance their operational reliability and ease of use. The 6-degree beach angle and the 150mm (5.9 inch) single lead STC-tiled 304SS conveyor are designed to optimize the discharge of solids, ensuring minimal carryover of drilling fluid. The robust 132 KW XP motor, compatible with 400/460V and 3-phase power at both 50 and 60 Hz, drives the hydraulic main drive and backdrive, providing consistent and powerful operation. The integrated 80:1 11 kNm gearbox, along with guards, feed tube, bearing lube system, and vibration switch/isolators, contribute to the overall safety and efficiency of the system. With PLC controls and ancillary tanks and pumps mounted on a skid base, these centrifuges are not only easy to install but also facilitate straightforward maintenance and operation. The 2012 vintage units are in very good condition and are currently located in the UK, making them a valuable addition to any drilling operation looking to enhance their mud management capabilities.

Key Features:

High-Speed Performance, Durable Construction, Efficient Solids Discharge, Advanced Control Systems, Robust Hydraulic Capacity